How Do Car Pressure Sensors Work?

Date:2025-12-10

- 1 1. What is a Pressure sensor for automobiles and Why is it Critical?

- 2 2. A Deep Dive into Automotive pressure sensor types and applications

- 3 3. Troubleshooting: Common symptoms of a failing tire pressure monitoring sensor (TPMS)

- 4 4. DIY Guide: How to test a car pressure sensor with a multimeter

- 5 5. Smart Replacement: Buying guide: OEM vs aftermarket car pressure sensors

- 6 6. What's Next? Exploring Future trends in automotive pressure sensor technology

- 7 FAQ

At its core, a Pressure sensor for automobiles is an electromechanical device designed to measure the force exerted by liquids or gases within a vehicle's various systems. Its fundamental role is to convert this physical pressure into an electrical signal, typically a voltage or frequency, that can be interpreted by the car's Engine Control Unit (ECU) or other onboard computers. Think of it as the car's nervous system, constantly sending real-time data about internal conditions. Without this continuous stream of information, modern automotive technology—fuel injection, emissions control, advanced safety features—would be impossible.

1. What is a Pressure sensor for automobiles and Why is it Critical?

The criticality of these sensors cannot be overstated. They are the unsung heroes that ensure your car runs efficiently, safely, and cleanly. For instance, by measuring manifold pressure, the ECU can calculate the precise amount of fuel to inject for optimal combustion, directly impacting power and fuel economy. In safety systems like ABS and airbags, pressure sensors provide the instantaneous data needed to deploy life-saving interventions in milliseconds. In essence, they transform your vehicle from a purely mechanical machine into an intelligent, responsive system, making them indispensable components in contemporary automotive design.

- Converts physical pressure into readable electrical signals for the ECU.

- Crucial for optimizing engine performance, fuel efficiency, and emissions.

- Provides essential data for active and passive safety systems (ABS, ESC, Airbags).

- Enables the complex functionalities of modern vehicles, from climate control to tire monitoring.

2. A Deep Dive into Automotive pressure sensor types and applications

The world of automotive sensors is vast, but pressure sensors are among the most varied and widely deployed. Understanding the different types is key to diagnosing issues and appreciating the complexity of your vehicle. These sensors are not one-size-fits-all; each is meticulously designed for a specific environment and pressure range. From the high-heat environment of the engine bay to the exposed conditions of a wheel, each sensor plays a unique role. A comprehensive look reveals a sophisticated network of components working in harmony to monitor and manage vehicle dynamics. This section will explore the primary categories, detailing their specific functions and the systems they empower.

2.1 Engine Management Sensors

2.1.1 Manifold Absolute Pressure (MAP) Sensor

The MAP sensor is a cornerstone of engine management. It measures the absolute pressure inside the intake manifold, which fluctuates with engine load and altitude. The ECU uses this data, along with RPM and temperature, to determine the engine's air mass flow rate. This calculation is vital for setting the correct fuel injection timing and duration, ensuring optimal combustion and power output across all driving conditions.

2.1.2 Barometric Air Pressure (BAP) Sensor

Often integrated with the MAP sensor, the BAP sensor measures the ambient atmospheric pressure. This reading allows the ECU to adjust engine parameters based on altitude. As air density decreases at higher elevations, the BAP sensor helps the ECU compensate by altering the air-fuel mixture, preventing performance loss and maintaining efficiency.

2.2 Safety and Control Systems Sensors

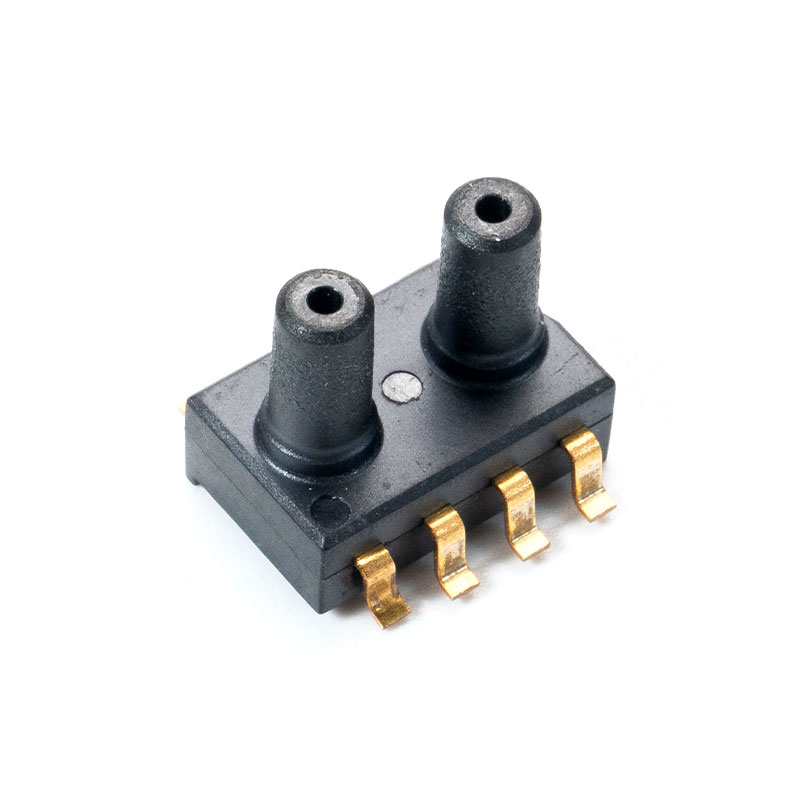

2.2.1 Tire Pressure Monitoring System (TPMS) Sensor

TPMS sensors are dedicated to monitoring the air pressure inside each tire. They directly contribute to safety by alerting the driver to under-inflation, which can lead to tire failure, reduced braking performance, and poor fuel economy. These sensors are typically battery-powered and transmit wirelessly to a central receiver.

2.2.2 Brake Fluid Pressure Sensor

Located within the anti-lock braking system (ABS) or electronic stability control (ESC) module, this sensor measures the hydraulic pressure in the brake lines. This real-time data is crucial for the ABS to modulate brake pressure during an emergency stop, preventing wheel lockup and allowing the driver to maintain steering control.

2.3 Other Key Applications

2.3.1 Air Conditioning (A/C) Refrigerant Pressure Sensor

This sensor monitors the pressure of the refrigerant on both the high and low sides of the A/C system. It prevents the compressor from engaging if pressure is too high or too low, protecting the system from catastrophic damage and ensuring efficient cabin cooling.

2.3.2 Oil Pressure Sensor

A critical safety component, the oil pressure sensor monitors the pressure of the engine oil. If the pressure drops below a safe threshold, it triggers a warning light on the dashboard, alerting the driver to a potentially catastrophic engine failure that could occur from inadequate lubrication.

3. Troubleshooting: Common symptoms of a failing tire pressure monitoring sensor (TPMS)

A failing TPMS can be a source of frustration and, more importantly, a safety hazard. Unlike other sensors, a TPMS fault is often directly communicated to the driver via a dedicated warning light. However, the symptoms can sometimes be ambiguous. Recognizing the specific signs of a TPMS issue versus an actual tire pressure problem is the first step in effective troubleshooting. The system is designed to be sensitive, and a malfunction can manifest in several ways, from constant false alarms to a complete lack of response when a tire is genuinely low. Understanding these nuances is key to maintaining both your safety and your peace of mind on the road.

3.1 The Tell-Tale Signs on Your Dashboard

The most obvious symptom is the TPMS warning light itself. A steadily lit TPMS light typically indicates that one or more tires have low pressure. However, if the light flashes for approximately 60-90 seconds when you start the car and then remains solid, this is a specific diagnostic code indicating a malfunction within the TPMS system itself, such as a dead sensor battery or a fault in the receiver module.

3.2 Physical Symptoms You Can Feel

While a faulty sensor won't change how the car drives, the underlying low tire pressure it's supposed to warn you about will. If you notice the car pulling to one side, a feeling of "sponginess" in the handling, or a thumping noise, and the TPMS light is off, the sensor itself may have failed. It's crucial to manually check your tire pressures with a gauge if you suspect any handling issues, regardless of what the dashboard says.

3.3 Inability to Reset the System

After inflating your tires to the correct pressure, most vehicles require a simple reset procedure for the TPMS light to turn off. If you've confirmed all tires are properly inflated and performed the correct reset procedure, but the light persists, it's a strong indication that one of the sensors is not communicating with the vehicle's computer.

4. DIY Guide: How to test a car pressure sensor with a multimeter

Testing a car pressure sensor, like a MAP sensor, with a digital multimeter is a straightforward diagnostic procedure that can save you time and money. This process allows you to verify if the sensor is responding correctly to changes in pressure and providing the right electrical signal to the ECU. While this guide focuses on a 3-wire MAP sensor (which has a 5-volt reference, a ground, and a signal wire), the fundamental principles can be adapted for other variable-resistance pressure sensors. Always consult your vehicle's service manual for specific wiring diagrams and voltage specifications before you begin. Safety is paramount, so ensure the engine is off and the key is out of the ignition before probing any electrical connectors.

4.1 Essential Tools and Safety Precautions

You will need a digital multimeter, the vehicle's service manual, and a set of back-probing pins or fine-piercing probes. Safety precautions include disconnecting the negative battery terminal to prevent accidental shorts, wearing safety glasses, and ensuring the engine bay is cool to the touch.

4.2 Step-by-Step Testing Process

- Locate and Access the Sensor: Find the MAP sensor, usually on the intake manifold or connected to it via a vacuum hose.

- Set Up the Multimeter: Set your multimeter to read DC Volts. Connect the black lead to a good engine ground.

- Check Reference Voltage: With the key ON but the engine OFF, carefully back-probe the reference wire (usually 5V) and the ground wire to confirm you have a stable 5-volt supply.

- Test Signal Output: Back-probe the signal wire. With the key still on, note the voltage reading at idle (no vacuum). It should correspond to atmospheric pressure. Then, apply a handheld vacuum pump to the sensor's vacuum port. As you increase vacuum, the voltage output should decrease smoothly and proportionally.

- Compare Readings: Compare your voltage readings at different vacuum levels with the specifications in your service manual. If the sensor does not respond or the readings are out of range, the sensor is faulty.

4.3 Interpreting the Results

If the sensor's output voltage is static, doesn't change with applied vacuum, or is outside the specified range, it is defective and must be replaced. If the reference voltage is missing, the issue lies in the wiring or the ECU, not the sensor itself. This test provides definitive proof of the sensor's health.

5. Smart Replacement: Buying guide: OEM vs aftermarket car pressure sensors

When a pressure sensor fails, you're faced with a critical decision: purchase an Original Equipment Manufacturer (OEM) part or opt for an aftermarket alternative. This choice often boils down to a trade-off between cost, quality, and compatibility. OEM parts are made by the vehicle's manufacturer or its official supplier, guaranteeing a perfect fit and function. Aftermarket parts are produced by third-party companies and can vary significantly in quality. Making an informed decision requires understanding the pros and cons of each. For example, a company like AutoSense Dynamics specializes in high-precision aftermarket sensors that often meet or exceed OEM standards, highlighting that the aftermarket landscape is not a monolith. The right choice depends on your vehicle, your budget, and your tolerance for risk.

5.1 Understanding OEM (Original Equipment Manufacturer) Sensors

OEM sensors offer the highest level of assurance. They are the exact same part used when the car was built, ensuring perfect compatibility with the vehicle's ECU and physical mounting points. The primary advantage is reliability and peace of mind, backed by the vehicle manufacturer's warranty. The main drawback is the significantly higher cost compared to most aftermarket options.

5.2 Exploring Aftermarket Sensor Options

The aftermarket provides a vast range of choices at various price points. High-quality aftermarket manufacturers, such as AutoSense Dynamics, invest heavily in research and development to produce parts that are reverse-engineered to meet or exceed OEM specifications. These can offer excellent value. However, the market also includes low-cost, low-quality parts that may fail prematurely or provide inaccurate data, potentially harming your vehicle's performance or efficiency.

5.3 The Final Verdict: A Decision-Making Framework

To help you decide, consider the following comparison matrix. It breaks down the key factors to weigh your options effectively.

| Feature | OEM Sensor | Aftermarket Sensor |

| Price | High | Low to Moderate |

| Quality & Reliability | Guaranteed High | Varies Widely (Research Brand) |

| Fit & Compatibility | Perfect, Guaranteed | Generally Good, Verify Part Number |

| Warranty | Typically 1 Year (Dealer) | Varies (Often Lifetime/Limited) |

| Best For | Newer cars, warranty concerns, peace of mind | Budget-conscious repairs, older vehicles, DIYers |

6. What's Next? Exploring Future trends in automotive pressure sensor technology

The role of the Pressure sensor for automobiles is evolving rapidly, driven by the megatrends of electrification, autonomy, and connectivity. The simple pressure transducers of the past are transforming into intelligent, multi-functional nodes within the car's complex electronic architecture. Future sensors will not only be more accurate and robust but will also be integrated with other technologies to provide richer, more contextual data. This evolution is critical for enabling advanced driver-assistance systems (ADAS) and fully autonomous driving, where a comprehensive understanding of the vehicle's physical state is non-negotiable. The pressure sensor is becoming a key enabler of the software-defined vehicle.

6.1 Integration with IoT and Vehicle-to-Everything (V2X) Communication

Future sensors will be integral parts of the Internet of Things (IoT). A TPMS sensor, for example, won't just alert the driver; it could communicate with a smart city infrastructure to report road hazards (like potholes that cause pressure loss) or with other vehicles (V2V) to warn them of a sudden deflation event. This data sharing will enhance overall traffic safety and efficiency.

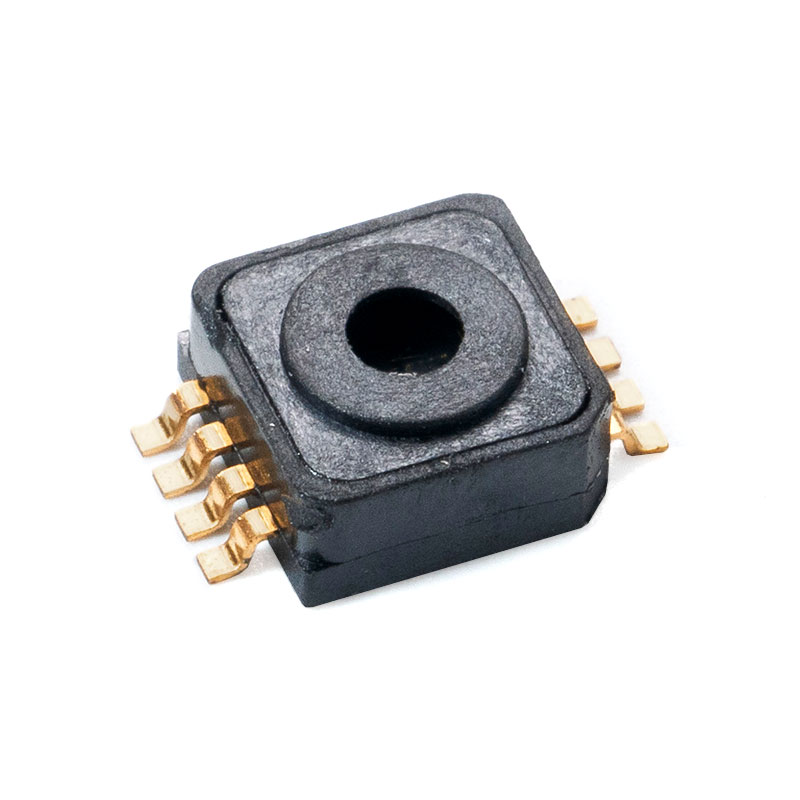

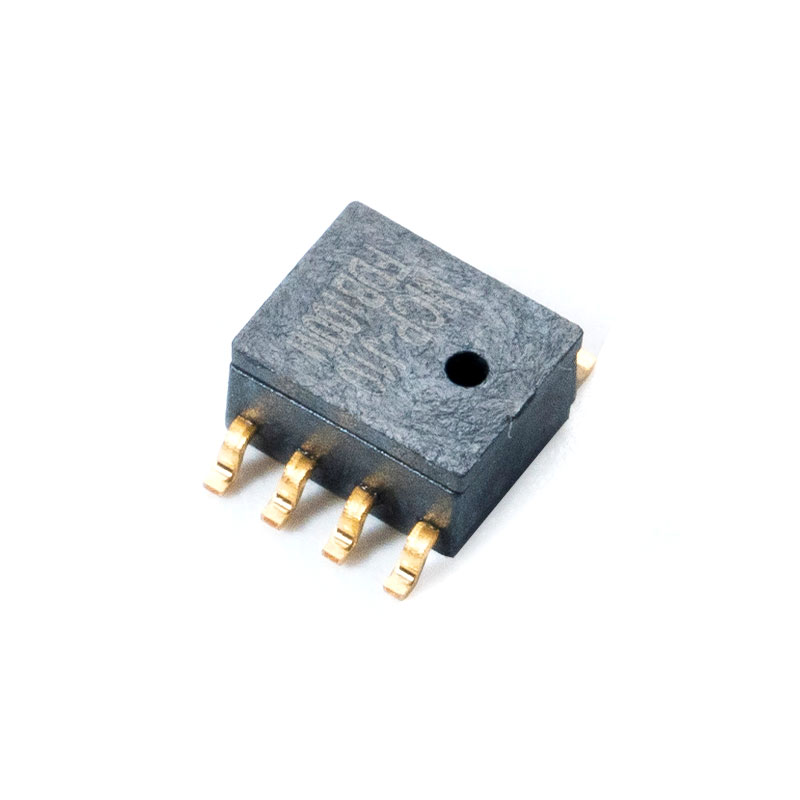

6.2 The Rise of MEMS Technology and Miniaturization

Micro-Electro-Mechanical Systems (MEMS) technology is leading to sensors that are smaller, more energy-efficient, and more sensitive than ever before. This miniaturization allows for sensors to be placed in new and more effective locations, such as directly within tire rubber or integrated into compact electric vehicle battery packs to monitor thermal pressure.

6.3 Smart Sensors with Built-in Diagnostics and AI

The next generation of sensors will be "smart." They will feature built-in microprocessors capable of performing self-diagnostics and even running simple AI algorithms. A smart oil pressure sensor could differentiate between a temporary pressure drop and a critical failure, providing a more nuanced alert to the ECU. This moves from simple data reporting to intelligent information processing, reducing the computational load on the central ECU and enabling predictive maintenance.

FAQ

How much does it cost to replace a car pressure sensor?

The cost to replace a car pressure sensor varies significantly based on the sensor type and whether you choose an OEM or aftermarket part. A simple aftermarket TPMS sensor can cost between $30-$100 for the part alone, with an additional $50-$150 for labor if done by a professional. More complex sensors like a MAP sensor are typically in the $50-$250 range for the part. OEM parts will always be on the higher end of this spectrum. Replacing a sensor yourself can save on labor costs, but it requires some technical skill.

Can I drive with a bad pressure sensor?

It depends on which sensor is faulty. Driving with a failed TPMS sensor is generally safe for a short time, as long as you manually check your tire pressures regularly. However, driving with a bad MAP sensor or oil pressure sensor is not recommended. A faulty MAP sensor can cause poor fuel economy, rough idling, and failed emissions tests. A failing oil pressure sensor is a critical safety risk; if it's not reading correctly, you might not get a warning before your engine suffers from catastrophic oil starvation.

Why is my tire pressure light on but my tires are fine?

This is a classic sign of a TPMS system malfunction, not a low tire. The most common cause is a dead battery in one of the wheel-mounted TPMS sensors, which typically lasts 5-10 years. Other causes include a damaged sensor during a tire change, a faulty TPMS receiver module, or the system needing a re-initialization after the tires were rotated. The flashing light upon startup is the key indicator that the system has detected an internal fault.

What is the most common car pressure sensor to fail?

The TPMS sensor is arguably the most common pressure sensor to fail, primarily due to its harsh operating environment. It's exposed to temperature extremes, moisture, road salt, vibration, and physical impact. Its internal battery also has a limited lifespan. After TPMS, the oil pressure sensor is another common point of failure, often due to engine heat and vibration over time, leading to internal leaks or electrical faults.

Are aftermarket pressure sensors as good as OEM?

Not all aftermarket sensors are created equal. High-quality aftermarket brands, like AutoSense Dynamics, use rigorous testing and quality control to produce sensors that meet or exceed OEM performance specifications. These can be an excellent value. However, low-cost, unbranded aftermarket parts can be unreliable, have poor fitment, or provide inaccurate data. The key is to research reputable aftermarket brands and read reviews before purchasing. For critical applications or if the car is under warranty, OEM is the safest choice.

Recommended Articles

English

English Français

Français 中文简体

中文简体