What Is a Medium Pressure Sensor?

Date:2026-02-23

- 1 Understanding Medium Pressure Sensors

- 2

- 3 Medium Pressure Sensor for Industrial Applications

- 4 Medium Pressure Sensor Accuracy and Range

- 5 Medium Pressure Sensor vs High Pressure Sensor

- 6 How to Choose a Medium Pressure Sensor

- 7 Applications Across Medical, Automotive, and Electronics

- 8 About Our Company

- 9 FAQ

- 9.1 What pressure range is considered medium pressure?

- 9.2 Are medium pressure sensors suitable for medical devices?

- 9.3 How does medium pressure sensor accuracy affect system performance?

- 9.4 What is the difference between medium and high pressure sensors?

- 9.5 How long do medium pressure sensors typically last?

Understanding Medium Pressure Sensors

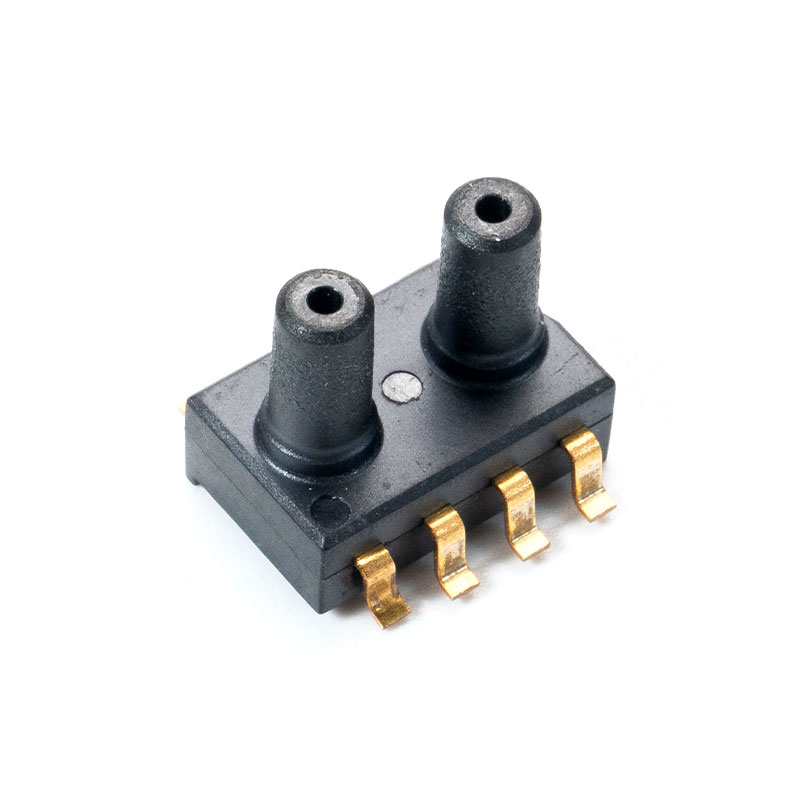

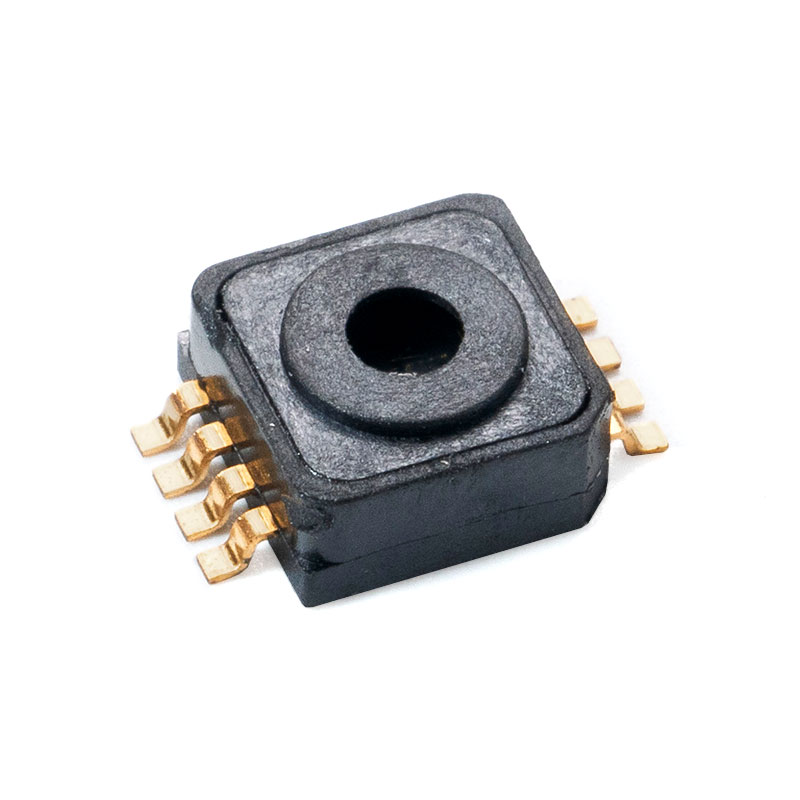

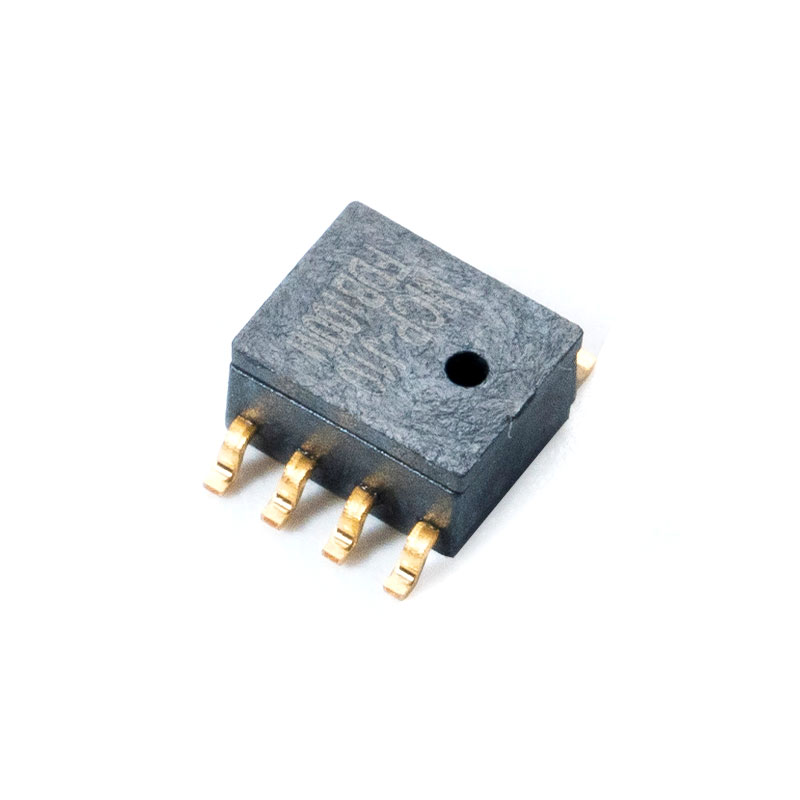

A Medium Pressure Sensor is a precision sensing device designed to measure pressure levels that fall between low-pressure and high-pressure ranges. These sensors are widely used in systems where stable, accurate pressure monitoring is essential but extreme pressure resistance is not required. Typically applied in industrial automation, medical equipment, automotive subsystems, and consumer electronics, medium pressure sensors offer an optimal balance between sensitivity, durability, and cost efficiency. Advances in microelectromechanical systems technology have further improved their accuracy, miniaturization, and long-term stability, making them suitable for compact and intelligent devices.

In practical use, a medium pressure sensor converts physical pressure into an electrical signal that can be processed by control systems or digital interfaces. This conversion enables real-time monitoring, feedback control, and safety protection across various applications. Compared with low-pressure sensors, medium pressure sensors are built with stronger diaphragms and broader measurement ranges. Compared with high-pressure sensors, they provide higher sensitivity and resolution within moderate pressure environments, ensuring precise data acquisition without unnecessary overengineering.

- Designed for moderate pressure measurement scenarios

- Balances sensitivity and mechanical strength

- Widely integrated into intelligent control systems

Medium pressure sensor working principle explained

The medium pressure sensor working principle is based on the deformation of a sensing element under applied pressure. When pressure is applied, the sensing diaphragm deforms slightly, causing a change in electrical properties that can be measured and converted into a standardized signal.

- Pressure-induced mechanical deformation

- Signal conversion through piezoresistive or capacitive structures

- Stable electrical output for system integration

| Component | Function |

| Sensing Diaphragm | Responds to applied pressure |

| Signal Circuit | Converts deformation into electrical output |

| Housing | Protects sensor from environment |

Medium Pressure Sensor for Industrial Applications

Medium pressure sensor for industrial applications plays a critical role in automation, fluid control, and equipment monitoring. In industrial environments, sensors must maintain accuracy under continuous operation, temperature variations, and mechanical vibration. Medium pressure sensors are commonly used in hydraulic systems, pneumatic control lines, compressors, and process monitoring equipment where consistent pressure feedback is required to ensure efficiency and safety.

By providing reliable real-time data, these sensors enable automated systems to adjust operations dynamically, reducing energy consumption and preventing equipment failure. Their robust construction and stable output make them well-suited for long-term industrial deployment.

- Used in hydraulic and pneumatic systems

- Supports automated process control

- Enhances system safety and efficiency

| Industrial Use | Sensor Role |

| Fluid Control | Maintains stable pressure levels |

| Automation Systems | Provides real-time feedback |

| Equipment Monitoring | Prevents overload and failure |

Medium Pressure Sensor Accuracy and Range

Medium pressure sensor accuracy and range are key performance indicators that determine suitability for specific applications. Accuracy refers to how closely the sensor output matches the actual pressure value, while range defines the minimum and maximum pressures the sensor can measure reliably. High accuracy ensures precise control and measurement, particularly in applications where small pressure deviations can impact performance or safety.

Several factors influence accuracy, including sensor design, temperature compensation, calibration methods, and signal processing. Modern sensors often incorporate built-in compensation techniques to minimize drift and maintain consistent readings across varying environmental conditions.

- Accuracy supports precise control and monitoring

- Proper range selection prevents sensor overload

- Calibration improves long-term stability

| Parameter | Description |

| Accuracy | Closeness to true pressure value |

| Range | Minimum and maximum measurable pressure |

| Stability | Consistency over time and conditions |

Medium Pressure Sensor vs High Pressure Sensor

When comparing medium pressure sensor vs high pressure sensor, the primary differences lie in sensitivity, structural design, and application focus. Medium pressure sensors are optimized for moderate pressure levels, offering higher resolution and sensitivity within their specified range. High pressure sensors, by contrast, are designed to withstand extreme pressures but may sacrifice sensitivity at lower levels.

Selecting between these sensor types depends on actual operating conditions. Using a high pressure sensor in a medium pressure environment may lead to reduced measurement precision, while using a medium pressure sensor beyond its rated range can compromise safety.

- Medium pressure sensors offer higher sensitivity

- High pressure sensors prioritize mechanical strength

- Correct selection improves system performance

| Aspect | Medium Pressure Sensor | High Pressure Sensor |

| Measurement Range | Moderate | Very High |

| Sensitivity | High | Lower |

| Typical Use | Automation and medical | Heavy industrial systems |

How to Choose a Medium Pressure Sensor

Understanding how to choose a medium pressure sensor involves evaluating both technical requirements and application conditions. Buyers should consider pressure range, accuracy, environmental exposure, output type, and compatibility with existing systems. A well-matched sensor improves reliability, reduces maintenance costs, and ensures consistent performance.

- Define required pressure range and accuracy

- Consider temperature and environmental factors

- Ensure electrical and mechanical compatibility

| Selection Factor | Importance |

| Pressure Range | Prevents overload |

| Accuracy | Ensures reliable data |

| Integration | Simplifies system design |

Applications Across Medical, Automotive, and Electronics

Medium pressure sensors are widely used across medical devices, automotive systems, and consumer electronics. In medical equipment, they support functions such as fluid delivery and respiratory monitoring. In automotive applications, they assist with fuel systems and air management. In electronics, compact sensor designs enable smart and portable devices.

- Medical devices requiring precise pressure control

- Automotive subsystems for safety and efficiency

- Consumer electronics with compact integration needs

About Our Company

Founded in 2011 and located in a national high-technology industrial zone known for innovation in connected systems, our company specializes in the research, development, manufacturing, and distribution of MEMS pressure sensors. With a strong technical team, scientific production management, and rigorous testing processes, we deliver high-performance sensing solutions that balance quality and cost efficiency.

- Expertise in MEMS pressure sensor technology

- Strict quality control and testing procedures

- Solutions used across medical, automotive, and electronics sectors

FAQ

What pressure range is considered medium pressure?

A Medium Pressure Sensor typically measures pressures ranging from several tens of kilopascals up to a few megapascals, depending on design and application requirements.

Are medium pressure sensors suitable for medical devices?

Yes, medium pressure sensors are widely used in medical equipment due to their high accuracy, stability, and ability to support precise pressure control.

How does medium pressure sensor accuracy affect system performance?

Higher accuracy ensures reliable measurements, which directly improves control precision, safety, and overall system efficiency.

What is the difference between medium and high pressure sensors?

When comparing medium pressure sensor vs high pressure sensor, medium pressure sensors offer better sensitivity for moderate ranges, while high pressure sensors are built for extreme pressure resistance.

How long do medium pressure sensors typically last?

With proper selection and operating conditions, medium pressure sensors can provide stable performance for many years, especially when supported by effective calibration and compensation.

Recommended Articles

English

English Français

Français 中文简体

中文简体