What Is an MCP Pressure Sensor?

Date:2026-02-09

- 1 Understanding the Core Technology

- 2 Exploring the Benefits of Miniature MCP Pressure Sensors

- 3 Performance Metrics: Precision and Cost

- 4 Industry Applications and Use Cases

- 5 Why Partner with MemsTech?

- 6 FAQ

In the rapidly evolving landscape of modern engineering and electronic design, the demand for precise, reliable, and compact sensing solutions is at an all-time high. Among the myriad of technologies available, the MCP Pressure Sensor has emerged as a critical component for a wide array of applications, ranging from intricate medical devices to robust automotive systems. These sensors, often built upon Micro-Electro-Mechanical Systems (MEMS) technology, offer unparalleled accuracy in measuring pressure changes, converting physical force into electrical signals that can be interpreted by microprocessors. As industries continue to push the boundaries of automation and smart technology, the role of advanced pressure sensing becomes pivotal. Engineers and developers are constantly seeking sensors that not only provide high-resolution data but also maintain stability under varying environmental conditions. Understanding the fundamental architecture and advantages of these sensors is the first step in leveraging their potential for innovative product development.

- Utilizes Micro-Electro-Mechanical Systems (MEMS) for high accuracy.

- Converts physical pressure changes into readable electrical signals.

- Essential for automation, medical devices, and automotive safety.

- Enables smarter, more responsive electronic systems.

Understanding the Core Technology

The technology behind an MCP Pressure Sensor is a marvel of modern micro-fabrication. At its core, this sensor typically consists of a diaphragm that flexes under pressure. This mechanical deformation is detected by piezoresistive or capacitive elements embedded within the sensor structure. The integration of MEMS technology allows these components to be microscopic in size yet incredibly robust. This miniaturization does not come at the cost of performance; rather, it enhances the sensor's ability to fit into tight spaces while consuming minimal power. The sophistication of these sensors lies in their ability to filter out noise and provide linear output across a wide range of pressures, making them indispensable in environments where precision is non-negotiable. As we delve deeper into the specifics, we see that the architectural design is fundamental to the sensor's overall reliability and efficiency.

- Features a microscopic diaphragm that reacts to pressure changes.

- Uses piezoresistive or capacitive sensing mechanisms.

- Offers linear output proportional to the applied pressure.

- Engineered to consume minimal power while maximizing performance.

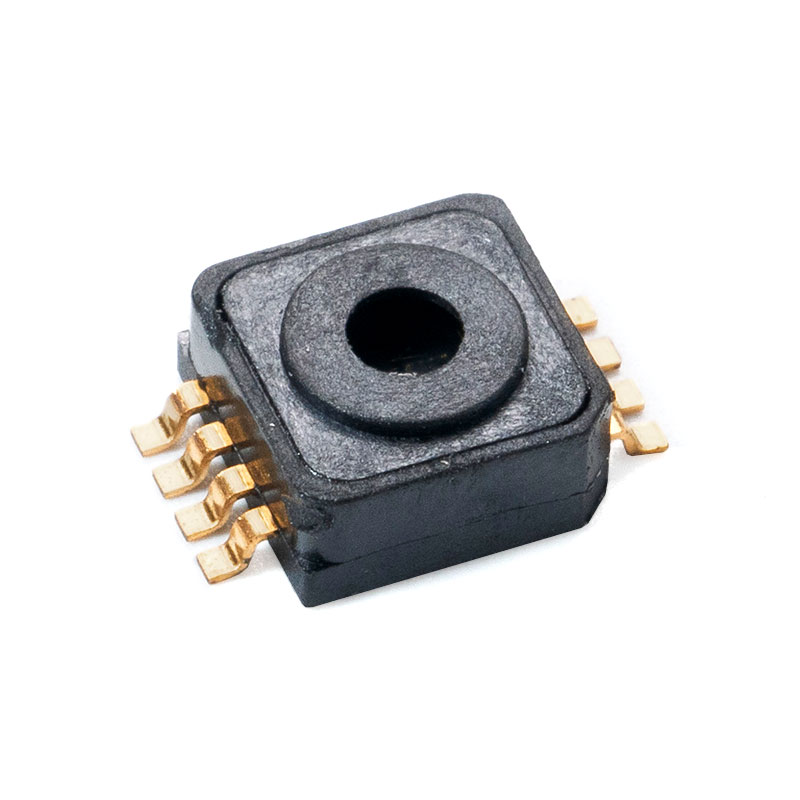

Defining the MCP Architecture

The architecture of an MCP Pressure Sensor is designed to withstand rigorous operating conditions while delivering precise data. The housing and packaging are as critical as the internal sensing element, providing protection against environmental factors such as humidity, dust, and temperature fluctuations. High-quality sensors often utilize stainless steel or specific ceramic coatings to ensure compatibility with corrosive media. The interface ports are carefully designed to ensure accurate pressure transmission without clogging or lag. This architectural integrity ensures that the sensor maintains its calibration over long periods, reducing the need for frequent maintenance and recalibration in industrial settings.

- Robust Packaging: Protects sensitive internal components from environmental damage.

- Media Compatibility: Uses materials resistant to corrosion and chemical exposure.

- Thermal Stability: Maintains accuracy across a wide operating temperature range.

- Signal Integrity: Shielded design minimizes electromagnetic interference.

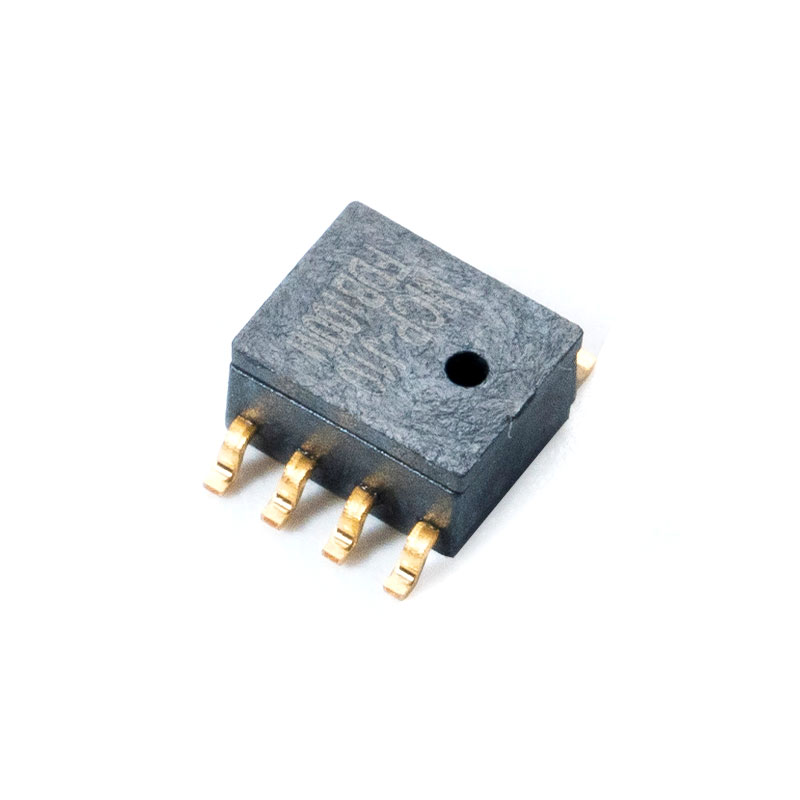

How MEMS Technology Enhances Performance

MEMS technology is the driving force behind the superior performance of modern pressure sensors. By fabricating mechanical elements on a silicon chip alongside electronics, MEMS enables mass production of highly consistent and reliable sensors. This integration reduces the signal path length, which improves the signal-to-noise ratio and response time. For applications requiring a miniature MCP pressure sensor, MEMS is the key enabler, allowing the entire sensor to be smaller than a fingernail while retaining high sensitivity. This technology also facilitates the incorporation of compensation circuits directly on the chip, correcting for temperature drift and non-linearity in real-time.

| Technology Feature | Performance Benefit |

| Silicon Micro-machining | Enables extremely small form factors and lightweight designs. |

| Integrated Electronics | Reduces noise and improves signal processing speed. |

| Batch Fabrication | Ensures high unit-to-unit consistency and reliability. |

| On-Chip Compensation | Corrects errors for temperature and non-linearity automatically. |

Key Advantages Over Traditional Sensors

Compared to older mechanical pressure sensing technologies, modern MCP Pressure Sensor units offer significant advantages. Traditional sensors often relied on moving parts that were prone to wear and tear, leading to drift and eventual failure. In contrast, the solid-state nature of MEMS-based sensors eliminates moving parts, resulting in a much longer lifespan and higher durability. Furthermore, these sensors provide better sensitivity and resolution, allowing them to detect minute pressure changes that mechanical sensors would miss. This capability is crucial in applications such as altitude monitoring or medical diagnostics where slight variations can indicate significant changes in status.

- Longevity: No moving parts results in less wear and longer operational life.

- Sensitivity: Capable of detecting extremely minute pressure variations.

- Cost-Effectiveness: MEMS production is scalable and economical.

- Vibration Resistance: Solid-state design is highly resistant to shock and vibration.

Why Size and Sensitivity Matter

In the world of IoT and wearable technology, size is a critical constraint. A miniature MCP pressure sensor opens up new possibilities for integrating pressure monitoring into devices that were previously too small to house such technology. Whether it is a smartwatch monitoring blood pressure or a drone measuring altitude changes, the reduced footprint allows for sleeker, more ergonomic designs. Sensitivity goes hand-in-hand with size; smaller diaphragms can often be designed to react more quickly to pressure changes, providing faster response times essential for dynamic systems.

| Attribute | Traditional Sensor | Miniature MEMS Sensor |

| Size | Bulky, requires significant mounting space | Compact, fits on PCBs and small devices |

| Power Consumption | Generally higher | Low power, suitable for battery operation |

| Responsiveness | Slower due to mechanical inertia | Fast response due to low mass |

| Integration | Often requires complex external circuitry | Easy integration with digital systems |

Exploring the Benefits of Miniature MCP Pressure Sensors

The trend toward miniaturization in electronics has necessitated the development of sensors that pack a punch despite their small size. The miniature MCP pressure sensor represents the pinnacle of this trend, offering high performance in a package that can fit on a fingertip. These sensors are particularly vital in the medical field, where they are used in catheters and implantable devices. Their small size means they can be placed closer to the point of measurement, leading to more accurate readings and faster physiological monitoring. Beyond medical uses, the consumer electronics sector relies heavily on these sensors to add functionality to smartphones, wearables, and home appliances without adding bulk.

- Enables advanced medical applications like catheter tip sensing.

- Essential for the slim profiles of modern consumer electronics.

- Allows for higher density of sensors on a single circuit board.

- Facilitates the development of unobtrusive wearable health monitors.

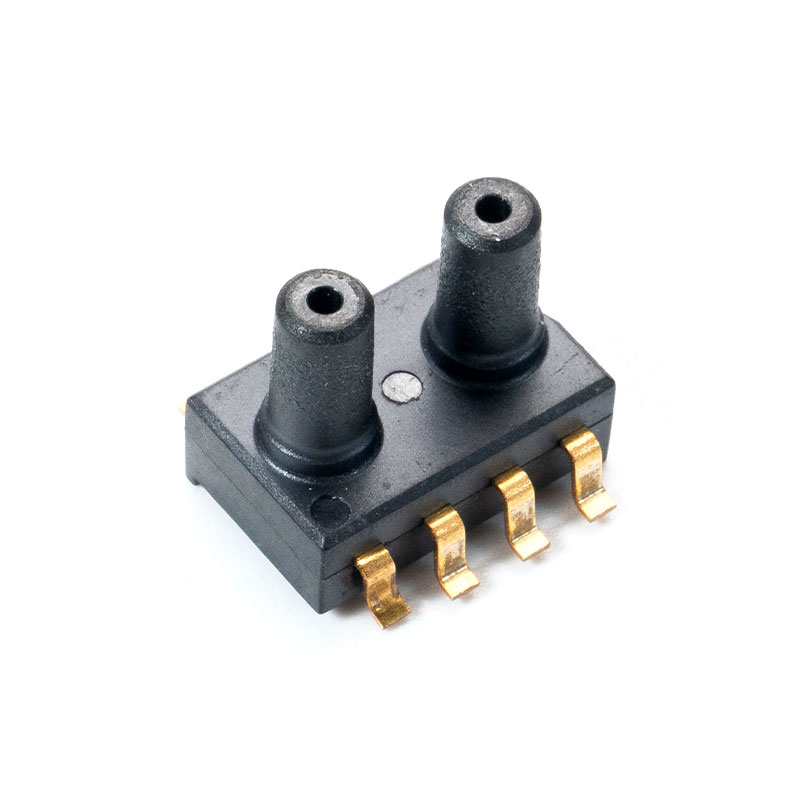

The Rise of Miniature MCP Pressure Sensor Designs

As consumer demand for smarter, smaller devices grows, the miniature MCP pressure sensor has become a standard component in design libraries. These sensors are now available in various form factors, including surface-mount devices (SMD) that can be placed by automated assembly robots. The rise of these designs correlates with the advancement of IoT, where billions of connected devices need to sense their environment to function effectively. The ability to measure air pressure, water pressure, or barometric pressure in such a small form factor allows for smarter environmental control systems and more intuitive user interfaces.

- Form Factor: Available in tiny SMD packages for automated assembly.

- IoT Integration: Critical for the functionality of smart connected devices.

- Versatility: Can measure barometric, water, or gas pressure depending on design.

- Scalability: Easy to scale production for high-volume consumer goods.

Integration in Wearable Technology

Wearable technology demands components that are lightweight, flexible, and energy-efficient. The miniature MCP pressure sensor fits these requirements perfectly. In smartwatches and fitness trackers, they are used to calculate altitude changes for floor tracking or to monitor blood pressure trends. The integration process involves careful placement to ensure the sensor port is exposed to the environment while the electronics remain protected. This seamless integration allows manufacturers to offer health and fitness features that users rely on daily, all without compromising the comfort or style of the wearable device.

| Wearable Device | Sensor Function | User Benefit |

| Smartwatch | Barometric pressure sensing | Tracks floors climbed and altitude |

| Fitness Tracker | Biometric pressure monitoring | Monitors blood pressure trends |

| Smart Clothing | Flex and pressure detection | Analyzes posture and movement |

| Health Patch | Subcutaneous pressure sensing | Continuous patient monitoring |

Medical and Industrial Applications

While consumer electronics get much of the spotlight, the industrial and medical sectors rely heavily on the precision of an MCP Pressure Sensor. In medical applications, the stakes are incredibly high; sensors used in ventilators and infusion pumps must provide accurate data to ensure patient safety. These sensors undergo rigorous testing to meet regulatory standards. In industrial settings, sensors monitor hydraulic systems, HVAC pressure, and process control loops. Here, durability and stability are paramount. The sensor must operate reliably in the presence of vibration, dust, and temperature extremes found on factory floors.

- Medical Devices: Critical for ventilators, infusion pumps, and blood monitors.

- Industrial Automation: Monitors hydraulic and pneumatic systems.

- Process Control: Ensures pressure remains within safe operating limits.

- Regulatory Compliance: Meets strict standards for safety and efficacy.

Precision in Non-Invasive Monitoring

One of the most exciting applications of high precision MCP pressure sensor technology is in non-invasive medical monitoring. By placing sensors on the skin, medical devices can estimate internal blood pressure without the need for needles. This requires extreme sensitivity to detect the subtle pulsations of blood vessels. High precision ensures that the readings are accurate enough to support clinical diagnosis. This technology is expanding access to healthcare, allowing patients to monitor their conditions at home with devices that were previously only available in hospitals.

| Monitoring Type | Sensor Requirement | Application Example |

| Blood Pressure | High precision & low drift | Wrist BP monitors |

| Respiration | Rapid response & sensitivity | Sleep apnea masks |

| Intracranial | Extreme miniaturization | Diagnostic catheters |

| Fetal Monitoring | Safe materials & accuracy | Prenatal care devices |

Performance Metrics: Precision and Cost

When selecting an MCP Pressure Sensor for a project, engineers must balance two critical factors: precision and cost. High precision often implies more complex manufacturing processes and stricter quality control, which can drive up the price. However, advancements in MEMS fabrication have bridged this gap significantly. Modern manufacturing techniques allow for mass production of highly precise sensors, driving down the unit cost. This democratization of technology means that high-performance sensing is no longer the exclusive domain of high-end aerospace or medical equipment but is now accessible to a wide range of mid-range consumer products as well.

- Balancing performance requirements with budget constraints.

- Mass production techniques are lowering the cost of precision sensors.

- Total cost of ownership includes longevity and stability, not just unit price.

- Selecting the right grade of sensor prevents over-engineering.

The Importance of High Precision MCP Pressure Sensor

A high precision MCP pressure sensor is defined by its low error margin and high resolution. In many technical applications, a standard deviation of just a few percent is unacceptable. For instance, in meteorological equipment or altitude tracking in drones, a small error can compound into significant navigation mistakes. High precision is achieved through superior sensor design, such as temperature compensation circuits and high-grade silicon sensing elements. These sensors ensure that the output signal is a true and accurate representation of the pressure being measured, providing system integrators with the reliable data they need to build safe and effective products.

- Accuracy: Minimal error margin ensures reliable data collection.

- Resolution: Capable of detecting minute changes in pressure.

- Stability: Maintains accuracy over time and temperature changes.

- Repeatability: Provides consistent output under identical conditions.

Signal-to-Noise Ratio and Resolution

The performance of a high precision MCP pressure sensor is often quantified by its signal-to-noise ratio (SNR). A high SNR means that the actual pressure signal is clear and distinguishable from electrical background noise. This is crucial in applications where the pressure changes are subtle. Resolution refers to the smallest change in pressure the sensor can detect. By optimizing the mechanical design of the diaphragm and using low-noise electronic amplifiers, manufacturers can produce sensors that offer both high resolution and a clean signal, essential for precision control systems.

| Performance Metric | Standard Sensor | High Precision Sensor |

| Accuracy Error | +/- 1.5% to 3% FS | +/- 0.1% to 0.5% FS |

| Resolution | Low, suitable for general use | High, detects minute fluctuations |

| Temperature Hysteresis | Noticeable drift | Minimal drift, compensated |

| Long-term Stability | Adequate | Excellent, minimal calibration needed |

Balancing Budget with Low Cost MCP Pressure Sensor

Cost optimization is a critical phase in product development. Utilizing a low cost MCP pressure sensor allows companies to create competitive products without sacrificing essential functionality. The key to finding a low-cost option is to identify the specific performance requirements of the application. If the application does not require extreme precision or wide temperature compensation, a standard grade sensor can be used. The reduction in cost is achieved by streamlining the packaging and using slightly less stringent calibration protocols while still maintaining the fundamental reliability of the MEMS core.

- Targeted Specs: Select sensors that meet necessary but not excessive specs.

- Streamlined Packaging: Simple housings reduce material costs.

- Volume Production: Higher volumes lead to lower per-unit costs.

- Reliability: Even low-cost sensors must meet basic reliability standards.

Economies of Scale in MEMS Production

The economics of MEMS manufacturing play a significant role in the availability of low cost MCP pressure sensor units. Because MEMS sensors are fabricated using techniques similar to semiconductor manufacturing, thousands of sensors can be produced on a single silicon wafer. This parallel production capability significantly lowers the cost per unit. As the technology matures, the yield per wafer increases, further driving down prices. This economic model allows manufacturers to offer high-performance sensors at price points that facilitate their use in everyday consumer goods like air compressors, tire pressure monitors, and home weather stations.

| Production Factor | Impact on Cost |

| Wafer Size | Larger wafers produce more sensors per batch, lowering cost. |

| Yield Rate | Higher yields mean fewer wasted resources and lower prices. |

| Automation | Automated testing and packaging reduce labor costs. |

| Standardization | Standardized designs reduce R&D and tooling expenses. |

Industry Applications and Use Cases

The versatility of the MCP Pressure Sensor is evident in its widespread adoption across diverse industries. From the depths of the ocean in subsea exploration to the upper atmosphere in drone flight, these sensors provide critical data that ensures safety and efficiency. Their ability to operate in harsh environments while delivering precise readings makes them a preferred choice for engineers. In the automotive sector, they are integral to engine management and safety systems. In the HVAC industry, they optimize energy usage by precisely monitoring pressure in refrigeration cycles. These real-world applications highlight the sensor's adaptability and essential role in modern technology.

- Automotive: Monitoring tire pressure and engine air intake.

- Aviation: Altimeters and cabin pressure control systems.

- Marine: Depth gauges and ballast control systems.

- Consumer: Coffee machines, air purifiers, and weather stations.

MEMS MCP Pressure Sensor Applications in Modern Engineering

The scope of MEMS MCP pressure sensor applications is expanding as engineers find new ways to utilize pressure data. In modern engineering, pressure is often used as a proxy for other physical parameters, such as flow rate, liquid level, or altitude. This indirect measurement capability makes the pressure sensor a versatile tool. For example, in HVAC systems, differential pressure sensors are used to detect clogged air filters. In agricultural drones, barometric pressure sensors provide altitude data for autonomous flight stabilization. These applications rely on the sensor's ability to provide stable and accurate data under dynamic conditions.

- Flow Measurement: Uses pressure drop across an orifice to calculate flow rate.

- Level Sensing: Measures hydrostatic pressure to determine liquid level.

- Altitude Sensing: Utilizes barometric pressure for flight stability.

- Leak Detection: Monitors pressure drops to identify system leaks.

Automotive Systems and Environmental Control

In the automotive industry, an MCP Pressure Sensor is a vital component for both performance and safety. They are used in Tire Pressure Monitoring Systems (TPMS) to alert drivers to under-inflated tires, improving fuel economy and safety. Inside the engine, Manifold Absolute Pressure (MAP) sensors provide data to the Engine Control Unit (ECU) to optimize the air-fuel mixture for combustion. Environmental control within the cabin also relies on these sensors to manage the HVAC system, ensuring passenger comfort and efficient defogging.

| Automotive Application | Sensor Role | Benefit |

| Tire Pressure Monitoring | Measures air pressure in tires | Improves safety and fuel efficiency |

| Engine Management (MAP) | Measures intake manifold pressure | Optimizes combustion performance |

| Brake Systems | Monitors hydraulic pressure | Ensures effective braking force |

| Cabin HVAC | Controls refrigerant pressure | Ensures efficient cooling |

Consumer Electronics Integration

The ubiquity of smart devices has led to a massive increase in the demand for MCP Pressure Sensor units in the consumer electronics sector. Smartphones use these sensors to improve GPS accuracy by determining altitude, distinguishing between being on a ground floor or a higher floor of a building. Smart home devices, such as robot vacuums, use pressure sensors to detect floor types or stair drops. Even wearable fitness gear utilizes them to track stairs climbed or vertical movement during a workout. This integration enhances the user experience by providing context-aware features.

- Smartphones: Enhances location services and navigation accuracy.

- Robot Vacuums: Detects obstacles like stairs or drops.

- Fitness Trackers: Tracks elevation and vertical activity.

- Smart Appliances: Optimizes washing machine cycle pressure.

Smart Home Devices

In the smart home ecosystem, pressure sensors contribute to automation and safety. Smart thermostats use barometric pressure sensors to monitor weather changes and adjust heating/cooling schedules proactively. Smart plumbing leak detectors use water pressure sensors to identify bursts or dripping pipes immediately. The MCP Pressure Sensor is ideal for these applications because of its low power consumption, allowing it to run on batteries for years. This reliability and efficiency are key to the seamless operation of a connected home.

| Smart Home Device | Sensor Function | Outcome |

| Smart Thermostat | Barometric pressure monitoring | Optimizes HVAC efficiency |

| Leak Detector | Water pressure monitoring | Prevents water damage |

| Smart Mattress | Body pressure mapping | Improves sleep quality analysis |

| Air Purifier | Airflow pressure check | Indicates filter replacement time |

Why Partner with MemsTech?

Choosing the right manufacturing partner is as crucial as selecting the right sensor technology. MemsTech, established in 2011 and located in the Wuxi National Hi-tech District—widely recognized as China’s hub for IoT innovation—stands at the forefront of sensor development. As an enterprise specializing in the R&D, production, and sales of MCP Pressure Sensor units, MemsTech combines geographical advantages with technical expertise to deliver superior solutions. The company's deep integration into the IoT ecosystem allows them to stay ahead of market trends and technological shifts, ensuring that clients receive cutting-edge products that meet the rigorous demands of the modern electronics landscape.

- Founded in 2011, bringing over a decade of experience.

- Located in Wuxi National Hi-tech District, the heart of China's IoT hub.

- Specializes in the full lifecycle: R&D, production, and sales.

- Committed to driving innovation in the MEMS pressure sensor sector.

Innovation at the Heart of Wuxi National Hi-tech District

Strategic location plays a pivotal role in MemsTech's ability to innovate. Situated in Wuxi National Hi-tech District, the company is surrounded by a network of technology partners, top-tier talent, and supply chain resources. This environment fosters a culture of continuous improvement and rapid prototyping. Being in China’s hub for IoT innovation means MemsTech has early access to emerging technologies and can collaborate with other tech leaders to refine MEMS MCP pressure sensor applications. This proximity to the pulse of the industry allows the company to adapt quickly to new market requirements and offer solutions that are both current and future-proof.

- Ecosystem Access: Immediate access to a rich technology supply chain.

- Talent Pool: Recruitment of skilled engineers from the region.

- Collaboration: Opportunities for R&D partnerships with local tech firms.

- Agility: Rapid response to market trends and customer needs.

Leveraging China’s IoT Hub for R&D

The Wuxi National Hi-tech District provides a unique advantage for R&D. The supportive government policies and infrastructure dedicated to high-tech manufacturing enable MemsTech to invest heavily in advanced testing equipment and cleanroom facilities. This investment ensures that every MCP Pressure Sensor produced meets stringent quality standards. The collaborative environment of the hub allows for the cross-pollination of ideas, driving the development of next-generation sensors that are smarter, smaller, and more efficient.

| Location Advantage | Benefit to Clients |

| Tech Ecosystem | Advanced components and materials readily available |

| Policy Support | Stable and favorable business environment |

| Logistics Hub | Efficient global distribution and supply chain |

| Innovation Culture | Continuous product improvement and new features |

Comprehensive Solutions from R&D to Sales

MemsTech offers a one-stop solution for clients looking for low cost MCP pressure sensor options or high-end precision units. The company manages the entire product lifecycle, from the initial concept and R&D to mass production and global sales. This comprehensive approach ensures total quality control. MemsTech's sensor products are widely used in critical sectors including the medical field, automotive industry, and consumer electronics. Their experience across these diverse sectors means they understand the specific compliance and performance requirements of each industry, allowing them to tailor their solutions effectively.

- End-to-End Management: Complete control from design to delivery.

- Industry Expertise: Deep knowledge of medical, automotive, and consumer sectors.

- Customization: Ability to tailor sensors to specific application needs.

- Global Reach: Sales network serving international markets.

Serving Medical, Automotive, and Consumer Electronics Sectors

Each industry has unique demands, and MemsTech excels at meeting them. In the medical sector, they provide sensors that prioritize accuracy and stability for life-saving equipment. For the automotive industry, they supply robust sensors capable of withstanding harsh road conditions and temperature extremes. In the fast-paced consumer electronics market, they deliver miniature MCP pressure sensor solutions that balance cost with performance. This versatility makes MemsTech a preferred partner for businesses looking to source reliable sensing components.

| Sector | MemsTech Focus |

| Medical | High precision, reliability, and biocompatibility. |

| Automotive | Durability, temperature resistance, and safety compliance. |

| Consumer Electronics | Low cost, small size, and high functionality. |

Quality, Management, and Value

At MemsTech, quality is not just a department; it is a corporate culture. The company adheres to scientific production management practices and rigorous packaging and testing protocols. Every high precision MCP pressure sensor undergoes extensive testing to ensure it meets the specified tolerances before it leaves the factory. This commitment to quality, combined with professional development and competitive pricing, allows MemsTech to consistently deliver high-performance, cost-effective sensing solutions. The company's philosophy is to provide value that goes beyond the product itself, offering peace of mind and technical support to all clients.

- Scientific Management: Streamlined processes ensure efficiency and quality.

- Rigorous Testing: Comprehensive validation of all sensor parameters.

- Professional Development: Continuous training of the technical team.

- Competitive Pricing: Best value without compromising on quality.

Rigorous Packaging, Testing, and Competitive Pricing

The final step in ensuring sensor reliability is packaging and testing. MemsTech utilizes advanced packaging techniques to protect the sensitive MEMS elements from mechanical stress and environmental contamination. Their testing protocols cover electrical, mechanical, and environmental stress tests to simulate real-world conditions. Despite these high standards, MemsTech maintains competitive pricing by optimizing production yields and supply chain logistics. This balance makes them a unique player in the market, offering MCP Pressure Sensor products that define both quality and value.

| Quality Aspect | MemsTech Standard |

| Packaging Technology | Hermetic and robust protection for sensor die |

| Electrical Testing | Full parametric testing for accuracy and drift |

| Environmental Testing | Thermal cycling, shock, and vibration tests |

| Cost Strategy | Efficient production for market-competitive pricing |

FAQ

What is the typical lifespan of an MCP Pressure Sensor?

The lifespan of an MCP Pressure Sensor generally depends on the operating environment and the specific application. However, due to the solid-state MEMS technology used in these sensors, they are designed for long-term reliability. Unlike mechanical sensors with moving parts that can wear out, MEMS sensors have a mean time to failure (MTTF) that often spans several years. Factors such as exposure to extreme temperatures, corrosive media, or pressure spikes exceeding the maximum rating can reduce the lifespan. Regularly operating within the sensor's specified parameters ensures maximum longevity.

English

English Français

Français 中文简体

中文简体