What Technical Parameters Determine the Long-Term Stability of an Absolute pressure sensor in Industrial Vacuum Packaging?

Date:2026-01-27

- 1 The Foundation: Absolute pressure sensor working principle

- 2 Key Technical Parameters Governing Long-Term Stability

- 3 Digital vs. Analog: Enhancing Stability with Digital absolute pressure sensor Technology

- 4 Proper Selection: Absolute pressure sensor vs gauge

- 5 Ensuring Ongoing Accuracy: Absolute pressure sensor calibration

- 6 Conclusion

In the high-stakes environment of industrial vacuum packaging, maintaining the integrity of the seal is paramount. Whether extending the shelf life of perishable food products or protecting sensitive electronic components, the precision of the vacuum level directly correlates to product quality and safety. Central to this process is the Absolute pressure sensor, which serves as the critical eye monitoring the evacuation process. Unlike relative sensors, an absolute pressure sensor measures pressure relative to a perfect vacuum, ensuring that the packaging process remains consistent regardless of atmospheric fluctuations. However, selecting a sensor that merely performs well at installation is insufficient. For B2B procurement managers and engineers, the true metric of value lies in long-term stability—the sensor's ability to maintain accuracy over thousands of cycles and under varying environmental stresses without drift.

As the industry moves towards greater automation and quality control, the demand for high-precision sensing solutions is surging. According to the 2024 Industrial Sensors Market Analysis by ISA (International Society of Automation), the global market for pressure sensors in industrial automation is projected to grow by 7.5% annually, driven primarily by the need for higher accuracy and IoT integration in manufacturing processes. This growth underscores a shift in engineering priorities: moving from simple functionality to sustained reliability. Ensuring long-term stability requires a deep dive into specific technical parameters, ranging from the physical material properties to the architecture of the signal output. By understanding these parameters, procurement professionals can make informed decisions that reduce downtime and maintenance costs.

Source: International Society of Automation (ISA) - 2024 Industrial Sensors Market Analysis

The Foundation: Absolute pressure sensor working principle

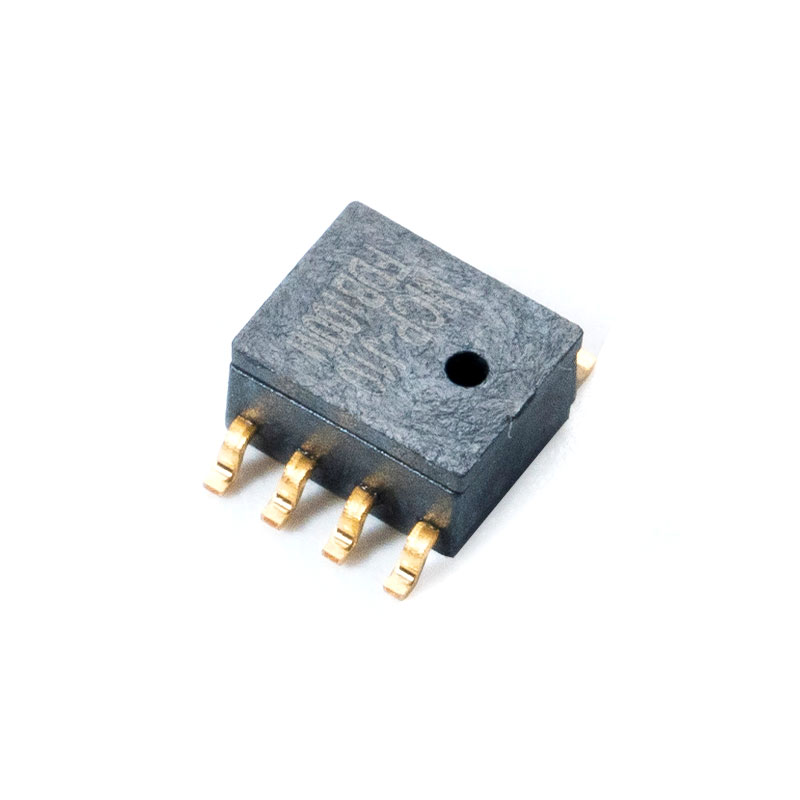

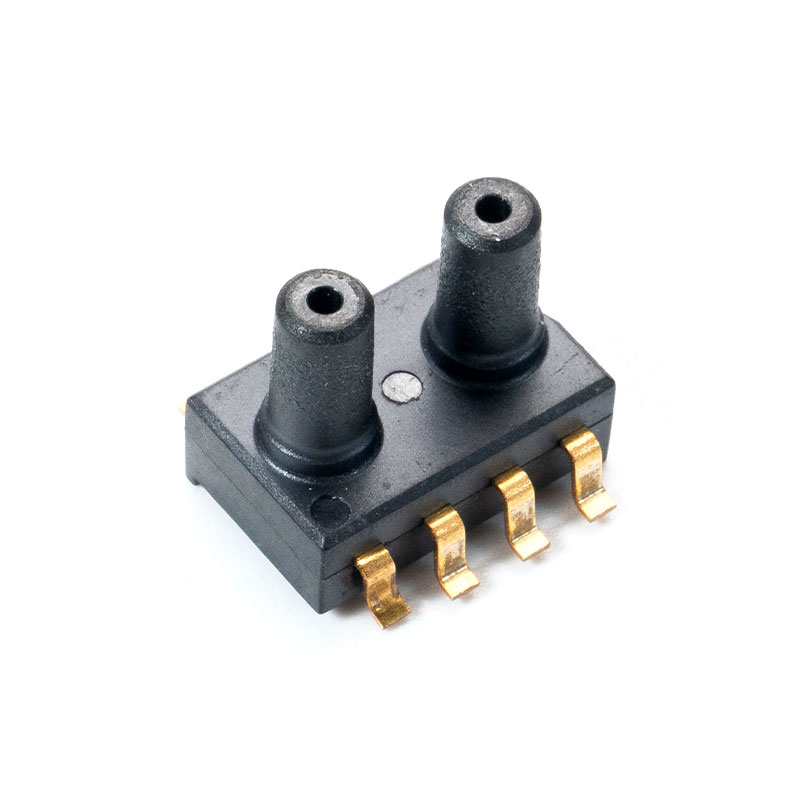

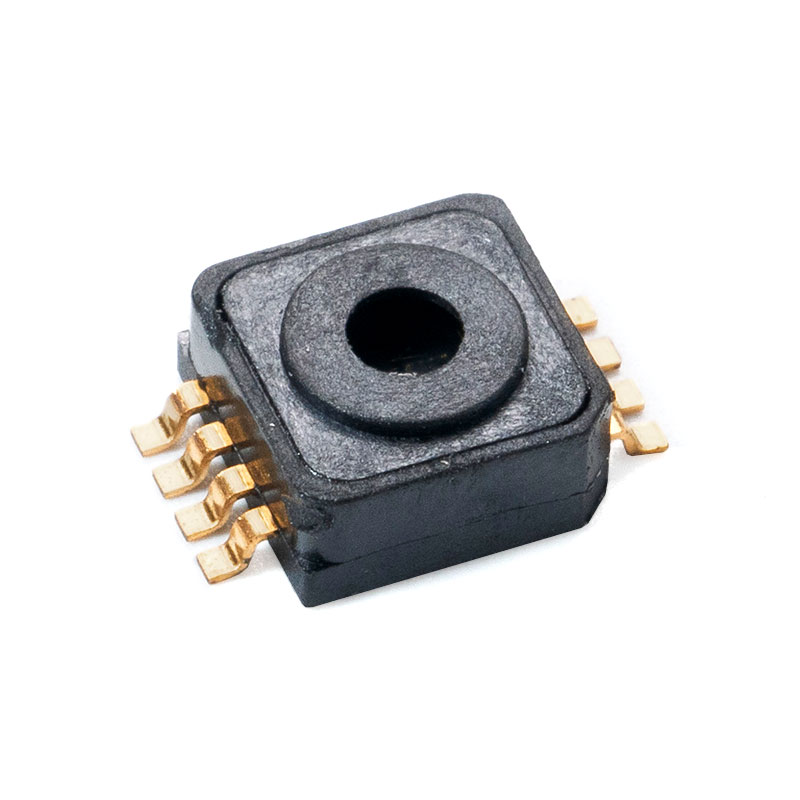

To understand stability, one must first grasp the mechanism of measurement. The Absolute pressure sensor working principle relies on a reference chamber maintained at a near-perfect vacuum (0 bar). The sensing element, whether piezoresistive or capacitive, deflects under external pressure, and this deflection is measured relative to this fixed vacuum reference. This design is distinct from gauge sensors, which reference ambient atmospheric pressure.

In vacuum packaging, this distinction is critical. If a manufacturer used a gauge sensor, a change in local weather (barometric pressure) would be read as a change in the vacuum package, leading to potential sealing errors even if the machinery is functioning perfectly. The long-term stability of an absolute sensor is heavily influenced by the integrity of this sealed vacuum reference. If the reference chamber degrades over time due to outgassing or micro-leaks, the sensor's zero point will shift, causing drift in the readings. Therefore, the hermeticity of the reference chamber is the first checkpoint for assessing long-term reliability.

Key Technical Parameters Governing Long-Term Stability

When evaluating sensors for industrial vacuum packaging, engineers must look beyond the initial accuracy specifications. Several specific parameters dictate how a sensor will withstand the rigors of continuous operation.

1. Total Error Band (TEB) and Long-Term Drift (LTD)

The most honest metric for stability is the Total Error Band (TEB), which accounts for all possible sources of error—including non-linearity, hysteresis, non-repeatability, and temperature effects—over a compensated temperature range. Within this, Long-Term Drift (LTD) is the specific parameter that indicates how much the sensor's output signal will change over a specified period, typically one year.

In vacuum packaging, where pressures might range from atmospheric down to 1 mbar (absolute), even a minute drift can result in significant quality variations. A sensor with a low LTD specification ensures that the calibration performed at the factory remains valid for extended periods, reducing the frequency of recalibration interventions.

2. Material Compatibility and Media Isolation

Industrial environments are harsh. Sensors are frequently exposed to aggressive cleaning agents (CIP - Clean in Place), humidity, and potentially corrosive gases generated by the packaged products. The interaction between the sensor's media contact materials and the environment is a primary cause of instability.

For example, using a sensor with stainless steel diaphragms (e.g., 316L) versus ceramic can yield different long-term results. While stainless steel is robust, it may be susceptible to certain chloride ions found in cleaning agents. Ceramic, conversely, offers excellent chemical resistance and high rigidity, which minimizes hysteresis. Ensuring the sensor material is compatible with process fluids prevents the degradation of the sensing surface, which is a leading cause of signal drift.

3. Temperature Effects and Thermal Hysteresis

Vacuum packaging lines often generate heat, or they may be located in environments with significant temperature swings. Temperature changes cause expansion and contraction of the sensor's mechanical structure. Thermal hysteresis refers to the sensor's ability to return to the same output point when the temperature returns to its original state.

If a sensor exhibits high thermal hysteresis, the vacuum readings will drift depending on whether the machine is warming up or cooling down. For high-precision applications, selecting a sensor with low thermal hysteresis coefficients is essential. This ensures that the vacuum level reading is a true reflection of the package pressure, not a byproduct of the ambient temperature.

4. Overpressure and Burst Pressure Ratings

Vacuum cycles can be violent. Rapid evacuation or accidental blockages can cause pressure spikes (positive pressure) that exceed the sensor's rated range. While a sensor might be rated for vacuum measurement, its ability to withstand occasional overpressure without permanent damage is vital for longevity.

- Overpressure Limit: The maximum pressure that can be applied without causing a change in performance specifications.

- Burst Pressure: The pressure at which the sensor mechanism will physically fail.

A robust sensor for industrial use should have a significant safety margin between its nominal measuring range and its burst pressure to survive accidental shocks, which preserves the internal alignment of the sensing element.

Digital vs. Analog: Enhancing Stability with Digital absolute pressure sensor Technology

The choice of output signal plays a surprising role in long-term stability. While analog signals (4-20mA or 0-10V) are standard, they are susceptible to electrical noise over long cable runs, which can be misinterpreted as pressure fluctuation. The Digital absolute pressure sensor offers a distinct advantage here.

Digital sensors, often utilizing protocols like I2C, SPI, or CANopen, incorporate microcontrollers and Application-Specific Integrated Circuits (ASICs) directly on the sensor head. These electronics can perform complex compensation algorithms in real-time. They actively correct for non-linearities and temperature effects—two major sources of instability—before the signal ever leaves the sensor. This onboard intelligence means the raw sensor element's imperfections are masked, resulting in a highly stable output signal that is immune to the electrical noise common in industrial factories packed with motors and variable frequency drives.

Comparing the two approaches highlights the stability benefits:

| Feature | Analog Sensor | Digital Sensor |

| Signal Integrity | Prone to noise and voltage drops over long distances, leading to reading instability. | Noise-immune binary transmission ensures data integrity remains exact from source to controller. |

| Temperature Compensation | Passive compensation (resistors) provides limited correction range. | Active compensation (ASIC) algorithms adjust for thermal effects across the entire range. |

| Diagnostic Data | Limited to pressure reading only; cannot predict internal drift or failure. | Can transmit diagnostic info (e.g., internal temperature) for predictive maintenance. |

Proper Selection: Absolute pressure sensor vs gauge

One of the most frequent errors in specifying sensors for vacuum packaging is confusing reference points. The debate of Absolute pressure sensor vs gauge is not merely academic; it has profound implications for process stability.

A gauge pressure sensor reads zero when vented to the atmosphere. As a vacuum is pulled, it reads a negative value (e.g., -900 mbar). The problem arises because atmospheric pressure at sea level is roughly 1013 mbar, but at high altitudes, it might be only 900 mbar. A gauge sensor is trying to measure relative to a moving target (the local atmosphere). Consequently, the actual vacuum level inside the package changes based on the weather, even if the gauge sensor reads the same number.

An absolute pressure sensor, referencing a vacuum, reads absolute zero. Whether the factory is in a valley or on a mountain, 100 mbar absolute is always the same level of vacuum. This stability of reference ensures that the sealing quality of the product remains consistent globally, regardless of local weather conditions. For industrial vacuum packaging, where product shelf life depends on an exact oxygen removal level, the stability offered by absolute referencing is non-negotiable.

| Aspect | Gauge Pressure Sensor | Absolute Pressure Sensor |

| Reference Point | Local atmospheric pressure (variable). | Perfect vacuum (fixed at 0). |

| Stability of Readings | Varies with weather and altitude; requires constant adjustment. | Constant regardless of environment; ensures repeatable vacuum levels. |

| Suitability for Vacuum | Low; cannot provide a true measure of remaining gas mass. | High; directly measures the total pressure within the package. |

Ensuring Ongoing Accuracy: Absolute pressure sensor calibration

Even with the most stable parameters and robust design, all sensors are subject to minute changes over their lifespan. A rigorous regimen of Absolute pressure sensor calibration is the final technical procedure that guarantees long-term stability. Calibration is the process of comparing the sensor's output against a traceable standard and adjusting it if necessary.

For vacuum packaging, this is particularly challenging because the calibration must simulate the vacuum environment, not just positive pressures. The technical stability of the sensor is validated by its calibration interval—the amount of time it can hold its specification within an acceptable tolerance window. A high-quality sensor will have a drift rate low enough to allow for calibration intervals of 1 to 2 years, whereas lower-grade sensors might require quarterly calibration. By integrating regular calibration into the maintenance schedule, engineers can verify the Long-Term Drift (LTD) predictions and ensure that the packaging process remains within strict quality control limits.

Conclusion

The long-term stability of an Absolute pressure sensor in industrial vacuum packaging is not determined by a single factor but by the synergy of the Absolute pressure sensor working principle, advanced digital compensation, robust material selection, and correct pressure referencing. By prioritizing parameters such as Total Error Band, thermal hysteresis, and chemical resistance, and by opting for Digital absolute pressure sensor solutions, industrial operators can achieve a level of consistency that protects product quality and optimizes operational efficiency. Understanding the difference in the Absolute pressure sensor vs gauge debate further ensures that the measurement data remains reliable regardless of external environmental fluctuations. Finally, adhering to a strict Absolute pressure sensor calibration schedule verifies that these technical parameters continue to perform over the long haul.

Frequently Asked Questions (FAQ)

- What is the primary difference between an absolute and a gauge pressure sensor in vacuum packaging?

An absolute pressure sensor measures pressure relative to a perfect vacuum (0 bar), providing a consistent reading regardless of altitude or weather. A gauge sensor measures relative to local atmospheric pressure, causing its readings to fluctuate with environmental changes, making it less stable for precise vacuum packaging.

- How does a digital absolute pressure sensor improve long-term stability?

A digital absolute pressure sensor uses onboard electronics (ASICs) to actively compensate for non-linearities and temperature effects in real-time. This digital processing corrects errors before the signal is transmitted, resulting in higher stability and immunity to electrical noise compared to analog sensors.

- Why is Long-Term Drift (LTD) a critical parameter for sensor selection?

Long-Term Drift (LTD) indicates how much the sensor's output will change over time (usually annually). In vacuum packaging, a low LTD ensures that the sensor maintains its accuracy for longer periods, reducing the frequency of recalibration and preventing quality drift in the production line.

- Can I use a gauge sensor if I only care about the pressure differential?

While theoretically possible for some mechanical applications, vacuum packaging usually requires the removal of a specific amount of gas mass (oxygen) to preserve the product. Since gauge readings vary with atmospheric pressure, they cannot guarantee a consistent vacuum level, whereas absolute sensors provide the necessary stability for quality assurance.

- How often should an absolute pressure sensor be calibrated in an industrial environment?

The calibration interval depends on the sensor's specified drift rate and the criticality of the application. For high-precision industrial vacuum packaging, high-quality sensors typically require calibration every 12 to 24 months to verify they are still operating within the desired Total Error Band.

English

English Français

Français 中文简体

中文简体