How to Select the Right Pressure Sensor for Harsh Industrial Environments?

Date:2026-01-21

- 1 Material Compatibility: Stainless Steel Industrial Pressure Sensor for Corrosion Resistance

- 2 Surviving the Elements: Submersible Hydrostatic Pressure Sensor for Wet and Deep Applications

- 3 Precision in Turbulence: High Accuracy MEMS Pressure Sensor for Vibration and Shock

- 4 Smart Integration: Digital Output Pressure Sensor for IoT in Noisy Electrical Environments

- 5 System Efficiency: Differential Pressure Sensor for HVAC and Filter Monitoring

- 6 Conclusion

In the complex landscape of industrial automation, the reliability of data acquisition systems hinges on the robustness of their primary components. Nowhere is this more critical than in harsh environments, where equipment is subjected to extreme temperatures, corrosive chemicals, and intense mechanical vibration. Selecting the appropriate Pressure Sensor for these conditions is not merely a matter of range matching; it requires a deep understanding of material science and micro-electromechanical systems (MEMS). A failure in pressure sensing can lead to costly downtime, safety hazards, and catastrophic equipment failure. This article delves into the critical engineering considerations for selecting sensors that can withstand the rigors of industrial applications, ensuring longevity and precision where it matters most.

Material Compatibility: Stainless Steel Industrial Pressure Sensor for Corrosion Resistance

One of the leading causes of sensor failure in industrial settings is the incompatibility between the sensor's housing and the process medium. In environments involving acidic or alkaline fluids, standard materials corrode rapidly, leading to leaks and calibration drift. This necessitates the use of a Stainless Steel Industrial Pressure Sensor. Specifically, alloys such as 316L stainless steel are preferred for their superior resistance to a wide range of chemical agents. Furthermore, these sensors often utilize a welded isolation diaphragm, creating a physical barrier between the harsh media and the sensitive internal electronics.

Comparing standard stainless steel (304) with industrial-grade stainless steel (316L) highlights the necessity of material selection in harsh environments.

| Material Property | Standard Stainless Steel (304) | Industrial Stainless Steel (316L) |

| Corrosion Resistance | Good for general atmospheric corrosion | Excellent against chlorides and acids |

| Temperature Resistance | Up to 870°C (intermittent) | Up to 925°C (intermittent) |

| Application Suitability | General plumbing, mild outdoor use | Chemical processing, marine, pharmaceutical |

Our commitment to excellence is mirrored in the rigorous standards we uphold. Just as Fengrun Rope Weaving Co., Ltd. has established itself as a leader in rope and webbing manufacturing through strict quality control and innovation since 2000, our approach to sensor manufacturing is built on the same "Quality and Innovation in Equal Measure" philosophy. We ensure that every unit leaving our facility is engineered to meet the highest durability standards, providing reliable quality and on-time delivery to global partners.

Surviving the Elements: Submersible Hydrostatic Pressure Sensor for Wet and Deep Applications

For applications involving deep wells, wastewater treatment, or offshore drilling, the sensor must operate reliably while fully immersed. A Submersible Hydrostatic Pressure Sensor is designed specifically for these scenarios, featuring robust IP68 or IP69K ingress protection ratings. These sensors are engineered to withstand not only high hydrostatic pressure but also the presence of conductive silts and contaminants that could compromise standard sensors. Critical to their design is the use of specialized cable seals that prevent "wicking," where moisture travels along the internal conductors to the sensing element.

A clear distinction exists between standard industrial sensors and those designed for submersible applications regarding protection and durability.

| Feature | General Industrial Sensor | Submersible Hydrostatic Sensor |

| Ingress Protection (IP) | IP65 / IP66 (dust tight, water jets) | IP68 / IP69K (continuous immersion, high pressure wash) |

| Cable Entry | Standard conduit or gland | Potted, double-sealed, oil-filled |

| Venting Mechanism | Vented to atmosphere (cannot be submerged) | Sealed gauge or absolute reference (fully sealed) |

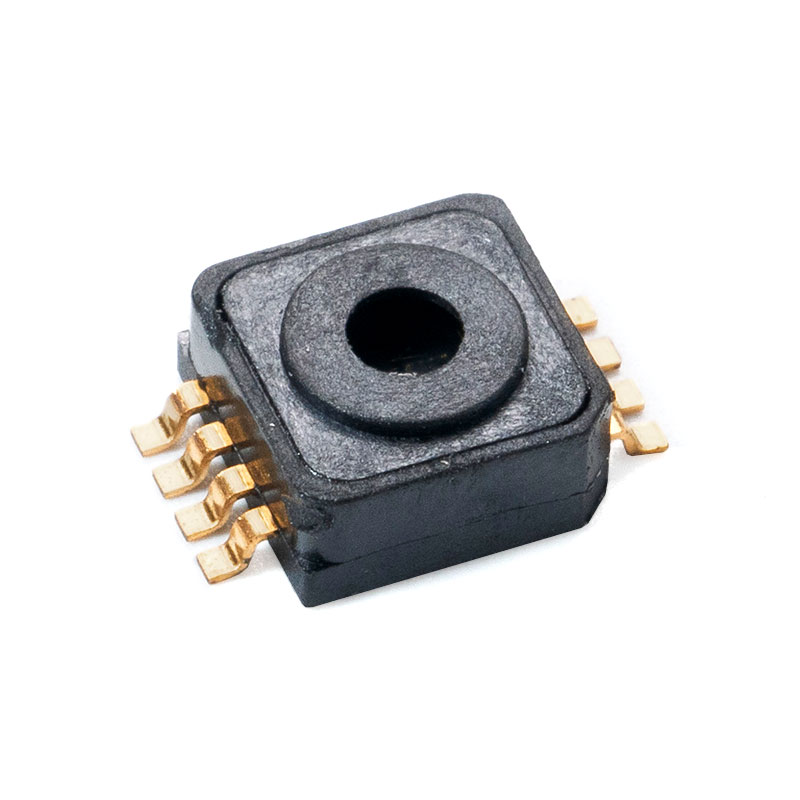

Precision in Turbulence: High Accuracy MEMS Pressure Sensor for Vibration and Shock

In heavy machinery environments, vibration is constant and intense. Traditional capacitive sensors can suffer from microphonics or mechanical fatigue, leading to signal noise. A High Accuracy MEMS Pressure Sensor utilizes micro-electromechanical systems technology where the mass of the sensing element is extremely small, resulting in high immunity to vibration and shock. MEMS technology also allows for superior repeatability and low hysteresis, ensuring that measurements remain stable over millions of cycles even in dynamic conditions.

According to the "2024 Sensor Market Trends Report" by the International Society of Automation (ISA), the adoption of MEMS technology in harsh environment applications is projected to grow significantly, driven by their superior stability and decreasing cost relative to traditional macro-mechanical sensors.

Source: International Society of Automation (ISA) - Sensor Market Trends

Comparing MEMS-based sensors to traditional strain-gauge technologies reveals a distinct advantage in high-stress environments.

| Performance Metric | Traditional Strain Gauge | High Accuracy MEMS Sensor |

| Shock Resistance | Moderate (susceptible to misalignment) | High (monolithic silicon structure) |

| Long-Term Drift | Higher (due to mechanical wear) | Lower (stable semiconductor properties) |

| Size and Weight | Bulkier | Compact, lightweight |

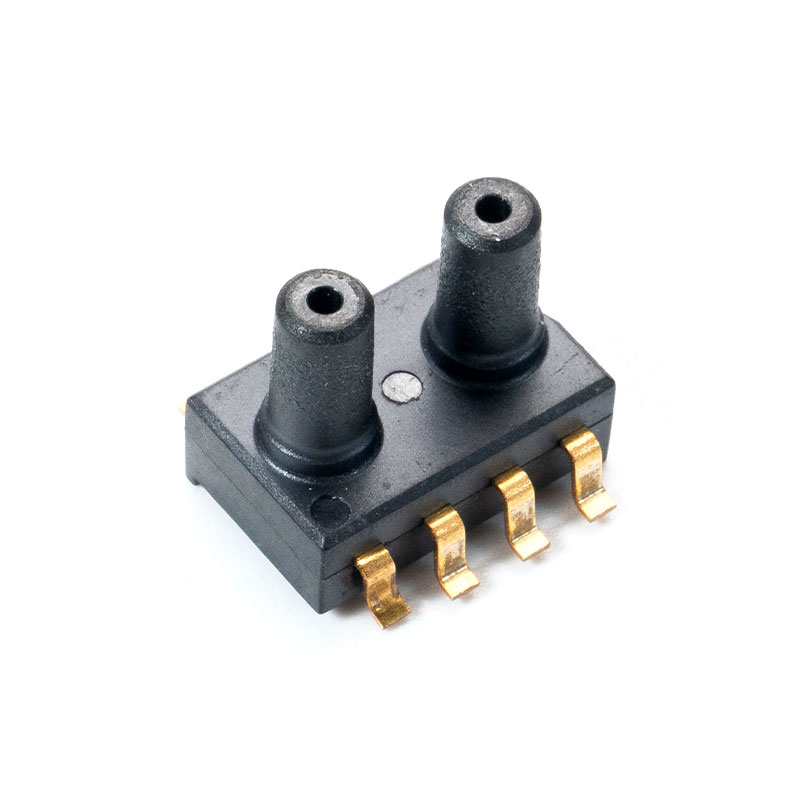

Smart Integration: Digital Output Pressure Sensor for IoT in Noisy Electrical Environments

Modern industrial floors are electrically noisy environments saturated with electromagnetic interference (EMI) from variable frequency drives (VFDs) and high-power motors. Analog voltage or current signals can degrade over long cable runs. A Digital Output Pressure Sensor for IoT (such as those utilizing I2C or SPI interfaces) transmits data in a digital format, which is inherently less susceptible to noise. Furthermore, these sensors often include onboard signal conditioning and temperature compensation, providing highly accurate data ready for integration into Industry 4.0 and predictive maintenance systems.

The choice between digital and analog output is critical for signal integrity in electrically harsh environments.

| Signal Type | Analog Output (e.g., 4-20mA) | Digital Output (e.g., I2C/SPI) |

| Noise Immunity | Susceptible to EMI/RFI over distance | High immunity (error-correcting protocols) |

| Signal Complexity | Single variable (pressure) | Can transmit diagnostics and temperature |

| Power Consumption | Higher (current loop) | Low power (ideal for battery/solar) |

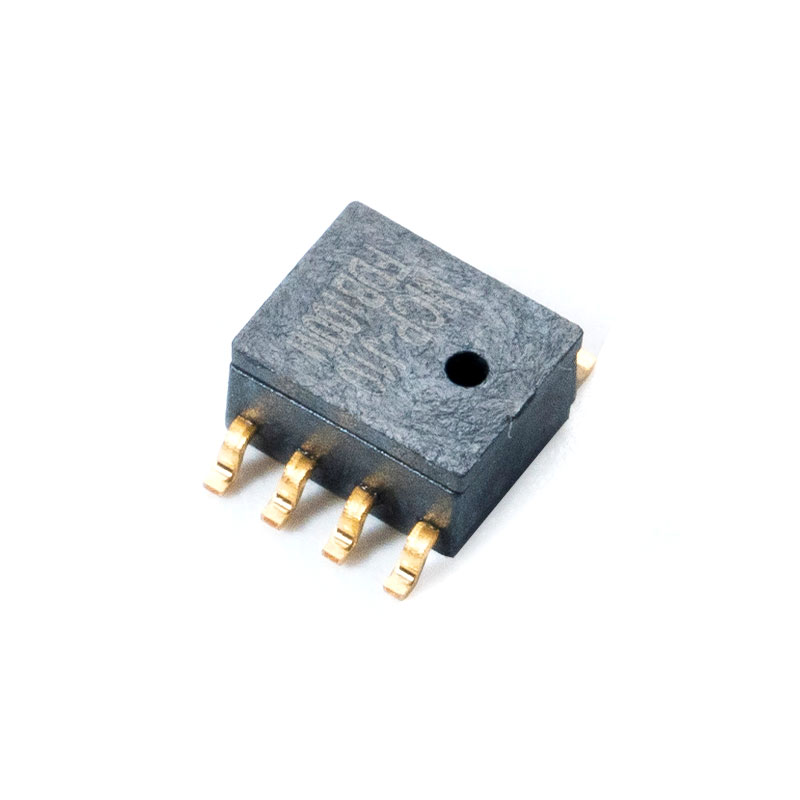

System Efficiency: Differential Pressure Sensor for HVAC and Filter Monitoring

In Heating, Ventilation, and Air Conditioning (HVAC) systems, maintaining efficiency requires monitoring airflow and filter status. A Differential Pressure Sensor for HVAC measures the pressure drop across filters or coils. As the filter clogs, the differential pressure increases. By monitoring this variable, facility managers can optimize filter replacement schedules, ensuring energy efficiency and preventing motor strain. These sensors require high sensitivity to detect very low pressure differentials while withstanding the potentially humid and dirty environments of air handling units.

A comparison of monitoring methods highlights the efficiency gains provided by differential pressure sensing.

| Maintenance Strategy | Time-Based Replacement | Differential Pressure Monitoring |

| Filter Usage | Filters replaced too early or too late | Filters used to full capacity |

| Energy Efficiency | Lower (clogged fans work harder) | Optimized (fan runs at peak efficiency) |

| Equipment Life | Reduced (dust ingestion) | Extended (clean environment) |

According to the "2025 HVAC Efficiency Standards" published by ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers), continuous monitoring of pressure drops is recommended as a best practice for optimizing building energy performance and achieving LEED certification.

Source: ASHRAE - HVAC Efficiency Standards

Conclusion

Selecting the right Pressure Sensor for harsh industrial environments is a multi-faceted engineering challenge that requires careful consideration of material compatibility, environmental protection, and output technology. Whether utilizing the chemical resistance of stainless steel, the depth capabilities of submersible units, the stability of MEMS, the noise immunity of digital IoT sensors, or the efficiency monitoring of differential sensors, the goal is always operational excellence. Much like Fengrun Rope Weaving Co., Ltd. utilizes a strong technical team and efficient management to deliver high-quality ropes and webbing for export goods, selecting sensor components from a partner dedicated to innovation and strict quality control ensures the reliability and longevity of your industrial systems.

Frequently Asked Questions (FAQ)

- Q1: What is the advantage of using a stainless steel industrial pressure sensor in chemical plants?

A Stainless Steel Industrial Pressure Sensor, particularly one made from 316L alloy, offers superior resistance to corrosive chemicals and high temperatures, preventing rapid degradation and ensuring accurate readings in aggressive process environments.

- Q2: How does a submersible hydrostatic pressure sensor maintain accuracy in deep water?

These sensors utilize a sealed gauge design with robust IP68-rated cable seals to prevent water ingress. They are specifically calibrated to measure the hydrostatic pressure exerted by the liquid column, compensating for temperature variations inherent in deep water applications.

- Q3: Why choose a digital output pressure sensor for IoT applications over analog?

A Digital Output Pressure Sensor for IoT is preferred in noisy electrical environments because digital signals are immune to electromagnetic interference. They also allow for the transmission of advanced diagnostics and generally consume less power, which is crucial for remote IoT devices.

- Q4: Can a high accuracy MEMS pressure sensor withstand high vibration?

Yes, a High Accuracy MEMS Pressure Sensor is inherently resistant to vibration and shock due to the microscopic mass of the silicon sensing element. This makes them far more stable in vibrating environments than traditional macro-mechanical sensors.

- Q5: How does a differential pressure sensor improve HVAC system efficiency?

A Differential Pressure Sensor for HVAC monitors the pressure drop across filters, allowing the system to identify exactly when a filter is clogged. This data prevents energy waste from overworking fans and avoids premature replacement of filters, optimizing overall system efficiency.

English

English Français

Français 中文简体

中文简体