MCP Pressure Sensor: A Technical Guide to Industrial Integration and Specifications

Date:2026-01-14

- 1 Introduction: The Role of Precision Sensing in Modern Industrial Systems

- 2 Part 1: Decoding the Datasheet: Core Specifications for Industrial Reliability

- 3 Part 2: System Integration: From Sensor Output to Reliable Data

- 4 Part 3: Application-Specific Implementation Strategies

- 5 Part 4: Calibration and Lifetime Performance Management

- 6 Conclusion: Engineering Robustness from Sensor to System

- 7 Frequently Asked Questions (FAQs)

- 7.1 1. Can I use a standard MCP series sensor in an automotive environment?

- 7.2 2. What is the simplest way to connect an MCP sensor to a PLC, not a microcontroller?

- 7.3 3. How often should I calibrate my MCP pressure sensors in the field?

- 7.4 4. What's the main benefit of a more expensive "high-accuracy" MCP sensor series?

- 7.5 5. My sensor output is noisy. Is it a faulty sensor or my circuit?

Introduction: The Role of Precision Sensing in Modern Industrial Systems

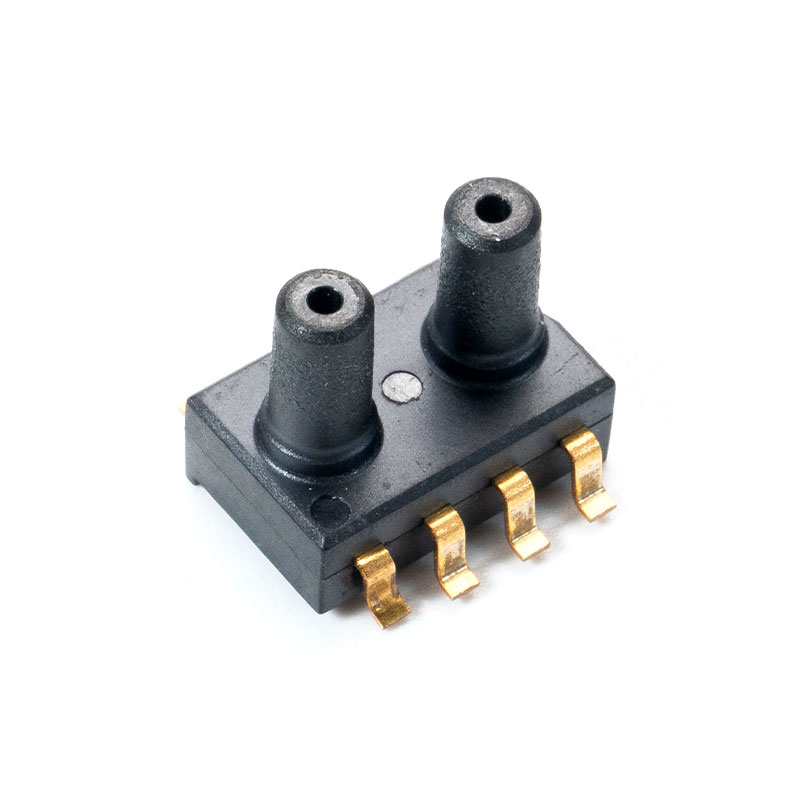

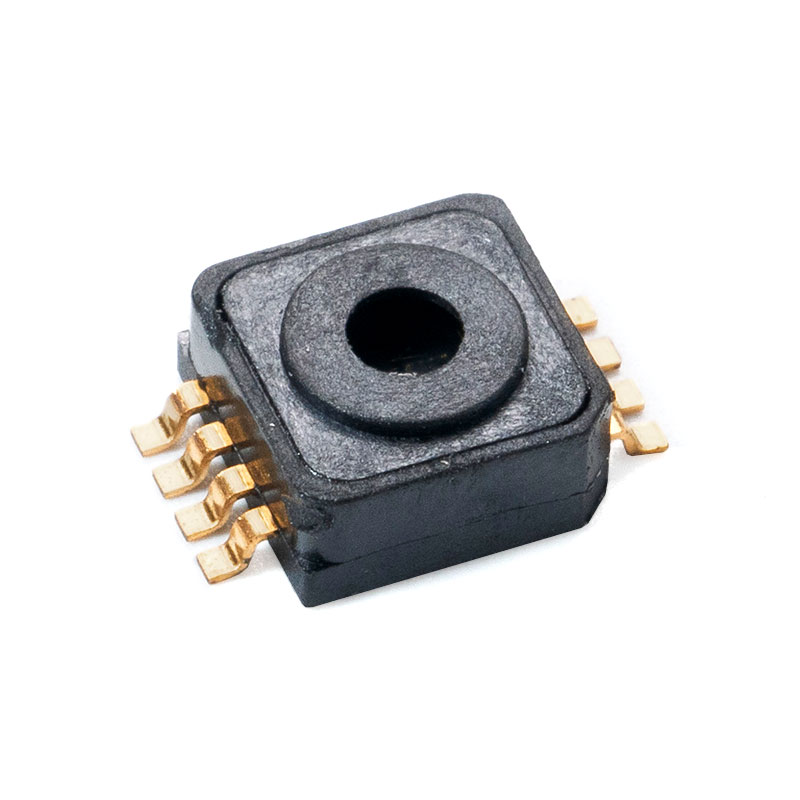

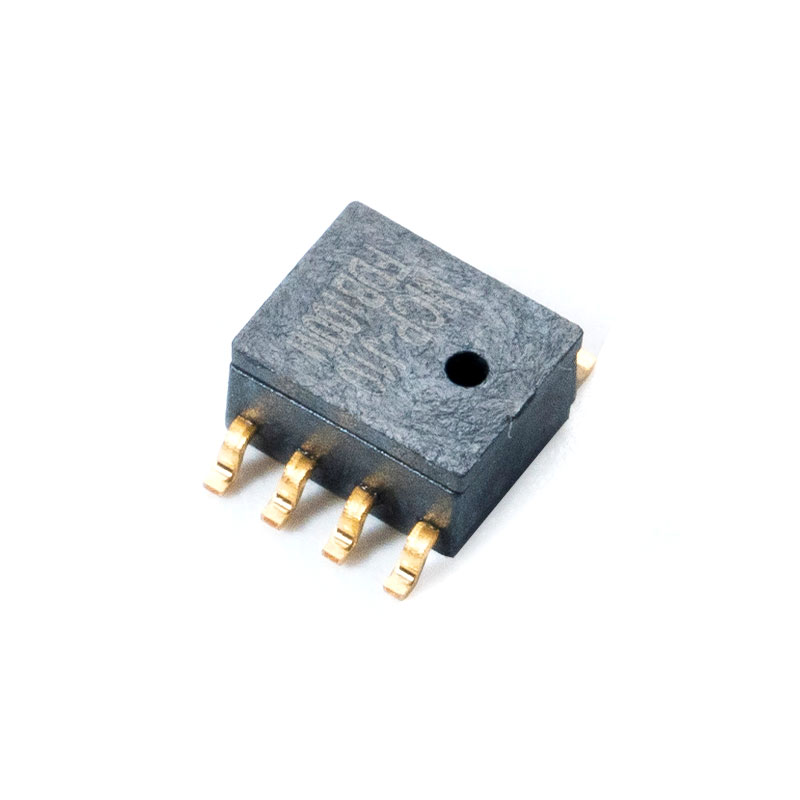

In industrial automation, precision measurement is foundational to control, safety, and efficiency. The MCP pressure sensor series, known for its robust analog output, serves as a critical component in translating physical force into actionable data. For system designers and B2B procurement specialists, selecting the right sensor extends beyond comparing datasheet figures. It requires a deep understanding of how key specifications—such as accuracy, temperature rating, and output characteristics—perform under real-world industrial stresses, from factory floor vibrations to extended temperature cycles. This guide provides an engineering-focused framework for evaluating, integrating, and deploying MCP pressure sensors effectively within demanding industrial systems.

Part 1: Decoding the Datasheet: Core Specifications for Industrial Reliability

Effective integration of an MCP pressure sensor for industrial automation systems begins with a forensic analysis of its specifications. These parameters define the sensor's performance envelope and its suitability for a specific task.

1.1 Accuracy: Beyond the Single Percentage Figure

Stated accuracy is a composite of several error sources. True evaluation involves dissecting the total error band (TEB) over the intended temperature and pressure range. For an MCP analog pressure sensor accuracy and calibration plan, you must consider:

- Initial Offset and Span Error: The deviation from ideal at room temperature, often correctable via calibration.

- Non-Linearity: The maximum deviation of the sensor's output from a best-fit straight line across its pressure range.

- Hysteresis: The output difference when approaching the same pressure point from ascending versus descending directions.

- Repeatability: The sensor's ability to produce the same output under identical conditions, a key metric for process consistency.

- Thermal Effects: The most critical factor for industrial and automotive use. This includes Zero-Temperature Offset (ZTO) and Span-Temperature Offset (STO), which dominate long-term error.

Understanding this decomposition is the first step towards specifying a viable MCP analog pressure sensor accuracy and calibration routine.

1.2 Environmental Ratings: Ensuring Robustness

Industrial and automotive environments present extreme challenges. A high temperature rated MCP pressure sensor for automotive applications, for instance, must survive under-hood ambient temperatures that can exceed 125°C. Key ratings include:

- Operating Temperature Range: The full span over which all specifications are guaranteed.

- Long-Term Stability: The expected drift in key parameters over time (e.g., ±0.5% FSO per year).

- Media Compatibility: The construction materials' resistance to process fluids, oils, or fuels.

- Electromagnetic Compatibility (EMC): Resilience to interference from motors, drives, and communication lines.

According to the latest market analysis by the global technical association, the demand for sensors capable of operating reliably above 125°C is growing at a compound annual rate of over 8%, driven primarily by electrification and increased thermal loads in automotive and heavy machinery. This underscores the strategic importance of specifying sensors with robust thermal performance from the outset.

Source: IEEE - Electronics Components and Technology Conference (ECTC) 2024 Proceedings - https://www.ieee.org/conferences/ectc

1.3 Series Comparison: Selecting the Optimal Variant

Manufacturers often offer multiple sensor series tailored for different performance and cost targets. Making an informed choice requires a clear difference between MCP and MS pressure sensor series (or other relevant families). The primary distinctions usually lie in performance tier, environmental hardening, and intended market.

| Comparison Parameter | MCP Series (Example: Standard Industrial) | MS Series (Example: High-Performance / Automotive) |

|---|---|---|

| Primary Application Focus | General industrial automation, HVAC, commercial equipment. | Automotive systems, harsh-environment industrial, mission-critical controls. |

| Typical Accuracy (TEB, incl. temp.) | ±1.5% to ±3.0% FSO | ±0.5% to ±1.5% FSO |

| Operating Temperature Range | -20°C to 105°C | -40°C to 150°C |

| Long-Term Stability | ±0.5% FSO/year | ±0.2% FSO/year |

| Key Certifications / Qualifications | RoHS, REACH | AEC-Q100, IATF 16949 (manufacturing site) |

| Typical Cost Factor | 1x (Base) | 1.5x to 3x |

This comparison highlights that the MS series, often marketed as an automotive-grade option, provides enhanced specifications essential for a high temperature rated MCP pressure sensor for automotive use-case, justifying its premium for critical applications.

Part 2: System Integration: From Sensor Output to Reliable Data

2.1 Signal Chain Design: The Interface Imperative

A common engineering challenge is how to interface MCP pressure sensor with microcontroller units (MCUs). The typical analog-output MCP sensor produces a small voltage signal (e.g., 0.5V to 4.5V) over its pressure range, which must be conditioned before ADC conversion.

- Power Supply Conditioning: Use a low-noise, regulated voltage supply. Decoupling capacitors (e.g., 100nF ceramic + 10µF tantalum) placed close to the sensor pins are non-negotiable for stability.

- Signal Amplification and Level-Shifting: If the output span doesn't match the ADC's input range, a precision operational amplifier circuit is required for scaling and offset adjustment.

- Noise Filtering: Implement an RC low-pass filter at the amplifier's output to suppress high-frequency noise. The cutoff frequency should be set 5-10 times higher than the signal's maximum frequency of interest to avoid attenuating the actual pressure signal.

- ADC Reference and Connection: Ensure the MCU's ADC uses a stable, low-drift voltage reference. Connect the conditioned signal to the ADC input using short, guarded traces.

2.2 Mitigating Real-World Industrial Noise

Industrial environments are electrically noisy. Beyond basic filtering, consider:

- Twisted-Pair or Shielded Cable: For remote sensor mounting, use twisted-pair wiring with the shield grounded at the controller end only to prevent ground loops.

- PCB Layout: Keep analog traces short, away from digital and power lines. Use a solid ground plane.

- Software Averaging: Implement oversampling and moving average filters in the MCU firmware to further enhance the signal-to-noise ratio.

Part 3: Application-Specific Implementation Strategies

3.1 Industrial Automation: Pneumatics, Hydraulics, and Process Control

In an MCP pressure sensor for industrial automation systems, the implementation varies by sub-application:

- Pneumatic Cylinder Control: Requires fast response time and good repeatability. Sensors are typically plumbed directly into air lines. Media compatibility with dry air is usually sufficient.

- Hydraulic System Monitoring: Demands very high pressure ratings and excellent long-term stability. The sensor must withstand pressure spikes and be compatible with hydraulic oil. A burst pressure rating of 3-4x the operating pressure is standard.

- Liquid Tank Level Sensing (via hydrostatic pressure): Needs high accuracy at low pressures and resistance to potential media corrosion. The calibration must account for the specific gravity of the liquid.

3.2 Automotive and High-Temperature Environments

Implementing a high temperature rated MCP pressure sensor for automotive applications adds layers of complexity:

- Harness and Connector Selection: Wiring and connectors must be rated for the same temperature range as the sensor.

- Thermal Management: In under-hood locations, consider heat sinking or placement away from exhaust components, even for a high-temperature device.

- Diagnostics: Automotive systems often require diagnostic capabilities, such as open-circuit, short-circuit, and plausibility checks, which may need to be implemented in the external interface circuitry.

Part 4: Calibration and Lifetime Performance Management

4.1 Implementing an Effective Calibration Regime

To achieve and maintain the specified MCP analog pressure sensor accuracy and calibration is an operational necessity. A two-point calibration (zero and full-scale) at room temperature corrects for initial offset and span error. For high-accuracy applications, a multi-point calibration across both pressure and temperature is required to characterize and correct for non-linearity and thermal drift. The resulting calibration coefficients are stored in the system's controller and applied to the raw ADC readings in real-time.

4.2 Partnering with a Qualified Supplier

For B2B procurement, the sensor supplier is a key partner for lifecycle performance. A reliable partner should offer:

- Technical Documentation: Comprehensive datasheets with guaranteed min/max specifications, not just typical values.

- Application Support: Access to engineering expertise for integration challenges.

- Consistency and Traceability: Strict process controls ensuring unit-to-unit consistency and full traceability of production lots.

- Quality Certifications: Adherence to international quality management standards (e.g., ISO 9001), which underpins product reliability.

For over two decades, our company has operated on this partnership model. We specialize in the technical manufacturing of sensing components, supported by a dedicated engineering team and strict quality control protocols. This foundation allows us to provide B2B clients with not just components, but reliable and consistent performance data, critical for integrating MCP pressure sensors into systems where failure is not an option.

Conclusion: Engineering Robustness from Sensor to System

Successfully deploying an MCP pressure sensor in an industrial context is a systems engineering task. It begins with a critical interpretation of specifications under the lens of the actual operating environment, proceeds through careful analog signal chain design to preserve data fidelity, and is sustained by a solid calibration strategy and a reliable supply chain. By following this disciplined approach, engineers can ensure that these critical sensors deliver the precision and reliability that modern industrial systems demand.

Frequently Asked Questions (FAQs)

1. Can I use a standard MCP series sensor in an automotive environment?

It is strongly discouraged. While it might function initially, a standard industrial MCP sensor likely lacks the extended temperature rating (up to 150°C), the long-term stability, and the specific qualification (like AEC-Q100) required for automotive reliability. The thermal drift and potential early failure in harsh under-hood conditions pose a significant system risk. Always select a variant specifically designed and tested as a high temperature rated MCP pressure sensor for automotive applications.

2. What is the simplest way to connect an MCP sensor to a PLC, not a microcontroller?

Most modern PLCs have analog input modules that accept voltage signals (e.g., 0-10V or 0-5V). First, ensure the MCP sensor's native output range matches the PLC's input range. If it doesn't, a small signal conditioner module is required to amplify/convert the signal. Always use shielded cable for the connection and ground the shield at the PLC end to minimize noise in the industrial environment, ensuring reliable data for your MCP pressure sensor for industrial automation systems.

3. How often should I calibrate my MCP pressure sensors in the field?

The calibration interval depends on the required system accuracy, the sensor's stated long-term stability, and the criticality of the application. For general industrial monitoring, annual calibration might suffice. For closed-loop control or safety-critical measurements, semi-annual or quarterly intervals may be necessary. The best practice is to perform an initial check after 3-6 months to establish a drift baseline for your specific application and set a data-driven interval. This proactive approach is key to managing MCP analog pressure sensor accuracy and calibration.

4. What's the main benefit of a more expensive "high-accuracy" MCP sensor series?

The primary benefit is a reduced total error band over temperature and time. This translates directly to improved process control, higher product quality, or reduced material waste. For example, in a precision injection molding process, a sensor with ±0.5% FSO error enables tighter pressure control than one with ±2.0% FSO, potentially leading to fewer defective parts. The cost of the higher-accuracy sensor is often quickly offset by operational savings and reduced downtime.

5. My sensor output is noisy. Is it a faulty sensor or my circuit?

Systematic troubleshooting is required. First, power the sensor from a clean bench-top power supply with proper decoupling capacitors directly at its pins. Measure the output directly with an oscilloscope. If the noise persists, the sensor may be faulty or exceptionally sensitive to EMI. If the noise disappears, the issue is in your integration circuit—revisit power supply regulation, grounding, PCB layout, and input filtering on your amplifier or ADC. Understanding how to interface MCP pressure sensor with microcontroller properly involves diagnosing such signal integrity issues.

English

English Français

Français 中文简体

中文简体