What Defines a Reliable MCP Pressure Sensor?

Date:2026-01-05

- 1 Understanding the Role of MCP Absolute/Gauge/Differential Pressure Sensor in Modern Measurement Systems

- 2 How Do Absolute, Gauge, and Differential MCP Sensors Actually Work?

- 3 Where Do MCP Pressure Sensors Provide Tangible Performance Advantages?

- 4 Performance Comparison: Absolute vs Gauge vs Differential MCP Sensors

- 5 FAQ

- 5.1 What is the key difference between an absolute and a gauge MCP pressure sensor?

- 5.2 Why are differential MCP sensors popular in HVAC and filtration systems?

- 5.3 Are MCP sensors suitable for digital microcontroller integration?

- 5.4 Which MCP sensor should be used for ultra-low pressure detection?

- 5.5 Is temperature compensation important in MCP pressure sensors?

Understanding the Role of MCP Absolute/Gauge/Differential Pressure Sensor in Modern Measurement Systems

The evolution of pressure-based measurement technologies has reshaped industries ranging from industrial automation to environmental monitoring. Among the most widely discussed sensor families today is the MCP Absolute/Gauge/Differential Pressure Sensor, known for its adaptability, high sensitivity, and strong compatibility with digital signal processing. As global demand for accuracy, compact device integration, and real-time diagnostics increases, engineers and researchers are actively searching for solutions that provide stable long-term performance under varying environmental conditions.

This article explores the working principles, application logic, and performance frameworks behind absolute, gauge, and differential architectures, while strategically embedding search-relevant long-tail keywords such as MCP absolute pressure measurement sensor, MCP industrial differential pressure sensor, MCP high-accuracy gauge pressure sensor, MCP low-pressure differential sensor, and MCP digital output MEMS pressure sensor. Through structured insights and clear comparison matrices, this guide aims to help users, engineers, and procurement professionals make informed decisions based on performance demands and system requirements.

- Clear classification of pressure sensing architectures

- Deep analysis of signal conditioning, calibration, and sensor output

- Comparative tables illustrating differences between absolute, gauge, and differential models

- Application-driven recommendations for engineers

| Pressure Type | Reference Point | Typical Use Case |

| Absolute | Vacuum | Altitude, environmental monitoring |

| Gauge | Ambient pressure | Pneumatic systems, pumps, compressors |

| Differential | Two pressure points | Filters, airflow, HVAC balancing |

How Do Absolute, Gauge, and Differential MCP Sensors Actually Work?

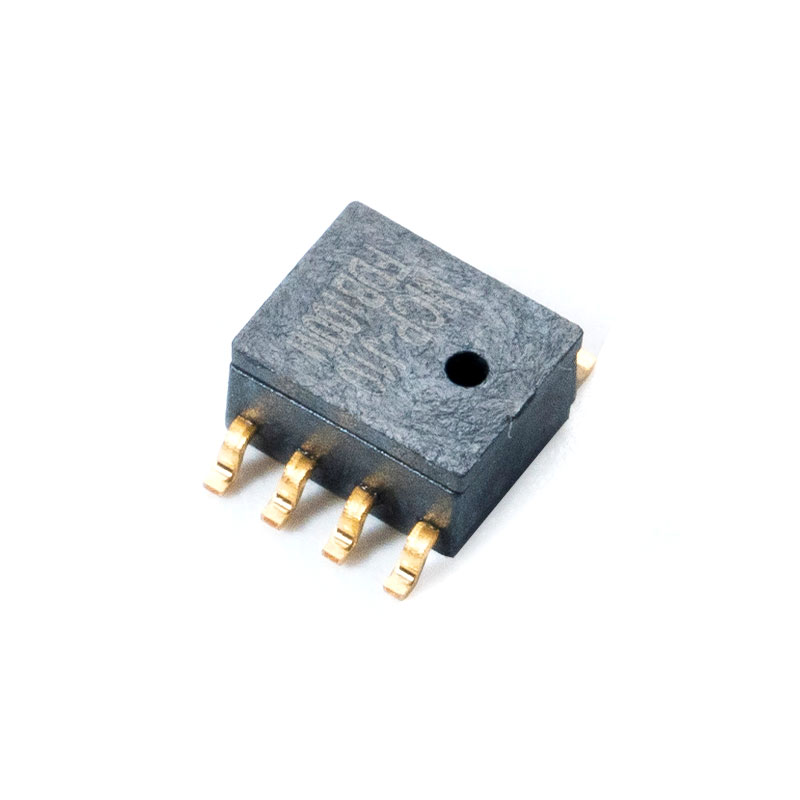

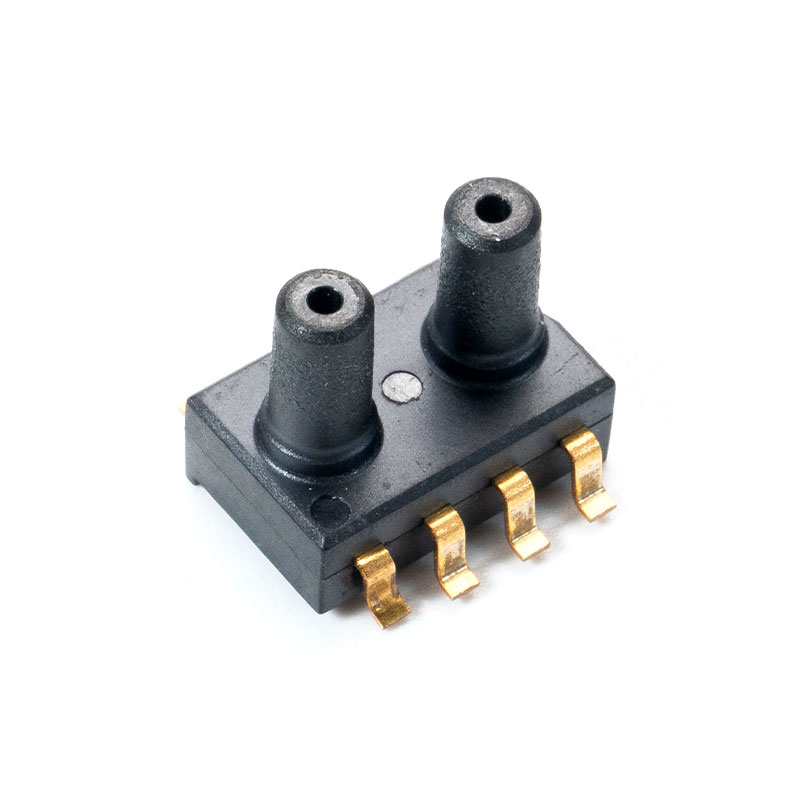

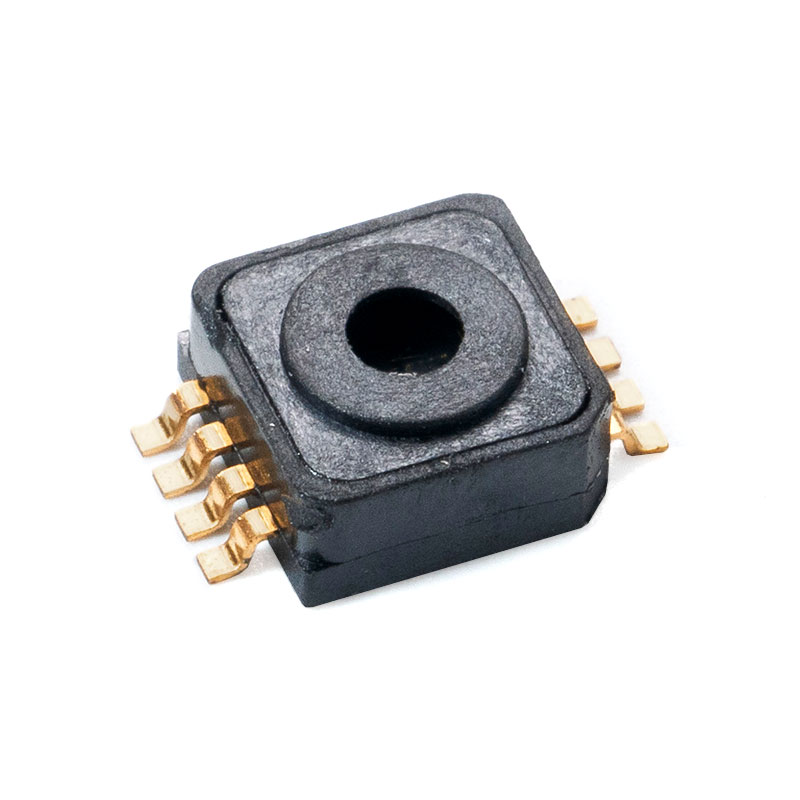

The operating logic of an MCP Absolute/Gauge/Differential Pressure Sensor is rooted in micro-electromechanical systems (MEMS) structures. These sensors typically rely on a silicon diaphragm equipped with piezoresistive or capacitive elements. When pressure is applied, mechanical deformation generates an electrical signal proportional to the applied force. Despite sharing a similar structural foundation, absolute, gauge, and differential models differ in reference points, output calibration, and environmental compensation mechanisms.

Absolute sensors rely on an internal vacuum chamber as the zero reference point. This makes the MCP absolute pressure measurement sensor suitable for applications requiring altitude stabilization, barometric readings, and aerospace-grade monitoring. Meanwhile, gauge sensors measure pressure relative to atmospheric pressure, making them essential in closed-loop pneumatic systems requiring real-time feedback. Differential sensors compare two input pressure ports, enabling precise monitoring of flow restrictions, filtration systems, and ventilation dynamics.

- Absolute sensors provide stable barometric references independent of weather fluctuations.

- Gauge sensors are ideal for mechanical equipment diagnostics and operational control.

- Differential sensors excel at monitoring pressure differences across components in HVAC, medical devices, and environmental chambers.

| Sensor Type | Reference Structure | Best Performance Environment |

| Absolute | Internal vacuum | Altitude sensing, atmospheric research |

| Gauge | Ambient air | Mechanical automation, compressors |

| Differential | Dual ports | Airflow, filters, medical ventilators |

Where Do MCP Pressure Sensors Provide Tangible Performance Advantages?

A key reason behind the rising popularity of the MCP industrial differential pressure sensor and its related models lies in their small form factor, high accuracy-to-cost ratio, and adaptability across multiple domains. Designed for integration into embedded systems, MCP sensors frequently incorporate digital output features such as I²C or SPI communication, allowing engineers to access stable, filtered data without external ADC modules.

In addition, environmental resistance, thermal compensation, and cross-sensitivity reduction techniques enable stable operation under challenging conditions. The MCP high-accuracy gauge pressure sensor is widely used for device diagnostics in industrial and automotive environments. Differential models support HVAC optimization, filtration monitoring, and smart building systems. When ultra-low pressure detection is essential, the MCP low-pressure differential sensor becomes the preferred choice thanks to its sensitivity and minimal drift characteristics.

- High-resolution digital output for microcontroller integration

- Broad pressure ranges supporting multi-industry requirements

- Strong temperature compensation enabling long-term stability

- Available in compact MEMS structures for lightweight system design

| Application Sector | Pressure Sensor Type | Recommended MCP Model Features |

| HVAC & Filtration | Differential | Low-pressure sensing, high stability |

| Industrial Equipment | Gauge | Shock resistance, real-time feedback |

| Environmental Monitoring | Absolute | High barometric accuracy |

| Medical Devices | Differential | Clean airflow monitoring |

Performance Comparison: Absolute vs Gauge vs Differential MCP Sensors

To help engineers select the most suitable device, the following matrix compares the behaviors, sensitivity ranges, accuracy differences, and typical real-world applications of three core sensor types. This comparison is especially useful for developers choosing between the MCP absolute pressure measurement sensor, the MCP high-accuracy gauge pressure sensor, and the MCP industrial differential pressure sensor.

| Feature | Absolute MCP Sensor | Gauge MCP Sensor | Differential MCP Sensor |

| Reference | Vacuum chamber | Ambient air | Two pressure ports |

| Precision Level | High | Medium–High | Very High |

| Main Output Type | Barometric | Mechanical system readings | Pressure difference |

| Environmental Compensation | Advanced | Moderate | Advanced |

| Typical Use | Altitude, weather | Pump/compressor monitoring | Flow & filter monitoring |

FAQ

What is the key difference between an absolute and a gauge MCP pressure sensor?

An absolute MCP sensor references a built-in vacuum chamber, making its readings unaffected by changes in weather or altitude. A gauge MCP sensor, by contrast, measures pressure relative to ambient air, which makes it best suited for mechanical and pneumatic systems. Users searching for stable environmental data typically choose the MCP absolute pressure measurement sensor.

Why are differential MCP sensors popular in HVAC and filtration systems?

The MCP industrial differential pressure sensor excels at detecting very small pressure changes between two points. This makes it ideal for monitoring filter blockages, airflow stability, and duct pressure balancing. Its sensitivity and low drift performance support long-term automated building management.

Are MCP sensors suitable for digital microcontroller integration?

Yes. Many models—especially the MCP digital output MEMS pressure sensor—support direct I²C or SPI communication. This eliminates the need for an external ADC and allows high-resolution, noise-filtered data to be accessed in real time.

Which MCP sensor should be used for ultra-low pressure detection?

For low-range airflow, medical ventilation, or micro-pressure systems, engineers typically choose the MCP low-pressure differential sensor due to its high sensitivity, low noise output, and stable zero-offset characteristics.

Is temperature compensation important in MCP pressure sensors?

Absolutely. Temperature fluctuations can cause signal drift. High-performance models—including the MCP high-accuracy gauge pressure sensor and similar variants—use advanced compensation algorithms to provide reliable output even under challenging environmental conditions.

Recommended Articles

English

English Français

Français 中文简体

中文简体