Why Micro Pressure Sensors Are Indispensable in Modern Technology

Date:2025-11-12

Introduction: Understanding Micro Pressure Sensors

Understanding Micro Pressure Sensors

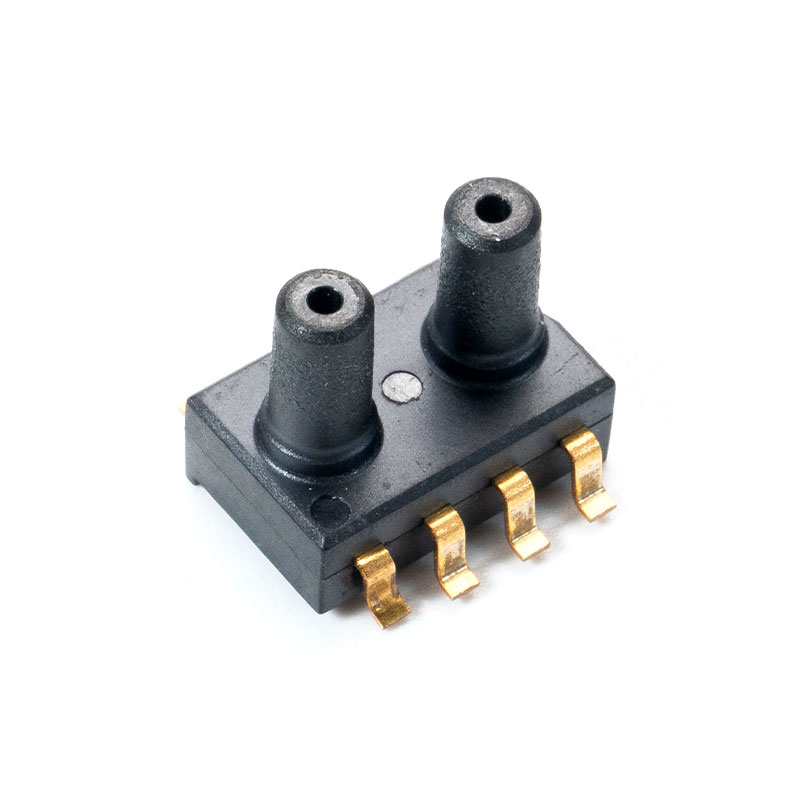

In the development of modern technology, Micro pressure sensors have gradually become essential components in numerous devices and systems. As the name suggests, a Micro pressure sensor is a sensor capable of detecting tiny pressure changes. Its core advantages include small size, high precision, and fast response. In fields such as industry, healthcare, aerospace, and smart devices, Micro pressure sensors not only perform the fundamental role of data acquisition but also serve as the "sensory organs" that enable intelligent and high-precision control.

The emergence and widespread use of Micro pressure sensors mark the transition from traditional large-scale pressure sensors to a new era of miniaturization, high precision, and intelligent technology. Compared with traditional sensors, Micro pressure sensors offer clear advantages in space utilization, power consumption, sensitivity, and integration capabilities, meeting the dual requirements of miniaturization and high performance in modern industrial and life scenarios.

Definition and Core Features of Micro Pressure Sensors

A Micro pressure sensor refers to a pressure sensor of very small size, capable of detecting and converting pressure signals within a micro-scale space. Its core features include:

- Miniaturization: Small in size and light in weight, suitable for confined spaces.

- High Precision: Able to detect minute pressure changes, ensuring reliable data.

- Fast Response: Quickly captures pressure changes for dynamic control and real-time monitoring.

- Low Power Consumption: Suitable for portable devices and smart terminals.

- Easy Integration: Can seamlessly integrate with electronic systems for intelligent control.

The Importance of Miniaturization

With the development of technology and the widespread use of smart devices, the demand for sensor miniaturization and high precision is growing. Traditional large-scale pressure sensors are often bulky, complex to install, and slow in response, making them unsuitable for modern devices. Micro pressure sensors can achieve high-precision pressure monitoring in limited spaces, which is crucial for medical instruments, micro-robots, drones, and automotive electronics.

Application Background

Micro pressure sensors are widely used in various fields, including:

- Medical devices: ventilators, blood pressure monitors, extracorporeal circulation equipment.

- Automotive electronics: tire pressure monitoring, engine pressure control, fuel injection systems.

- Industrial automation: pressure control, fluid monitoring, pneumatic system adjustment.

- Aerospace: flight pressure monitoring, drone altitude control.

- Smart devices: wearable devices, smart home environment monitoring.

From these applications, it is clear that Micro pressure sensors are not just sensors but key components enabling intelligent, high-precision control systems in modern technology.

Core Technology of Micro Pressure Sensors

MEMS Pressure Sensor Technology

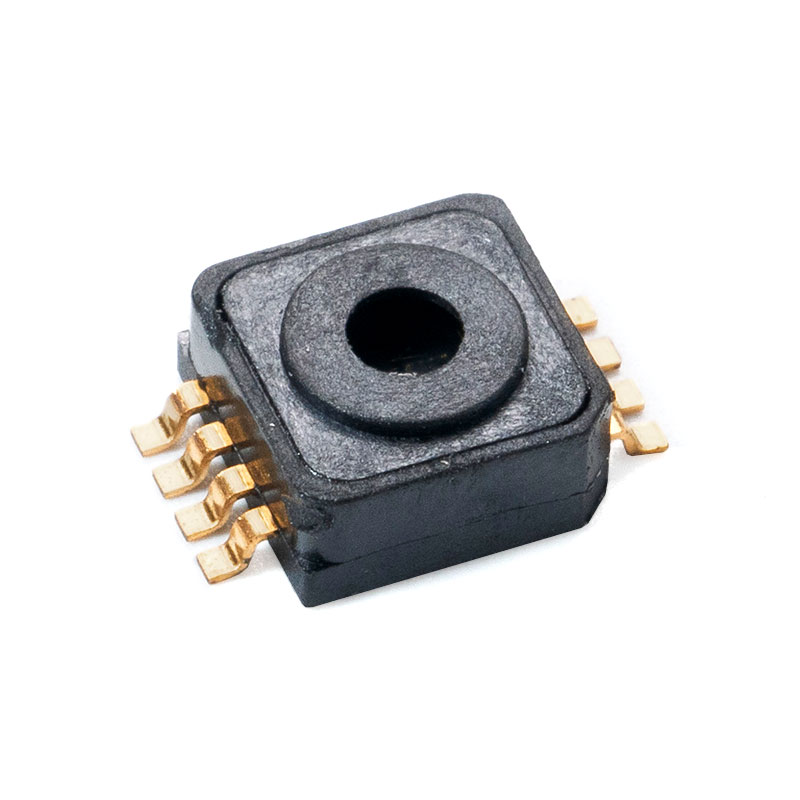

MEMS (Micro-Electro-Mechanical Systems) pressure sensors are Micro pressure sensors based on micro-electromechanical systems technology. They convert pressure signals into electrical signals through micro-mechanical structures, achieving high-precision measurement.

The advantages of MEMS technology include:

- High Precision and Sensitivity: MEMS structures convert small pressure changes into measurable electrical signals, reaching micro-Pascal levels of accuracy.

- Miniaturized Design: MEMS sensors can be reduced to a few millimeters or smaller, suitable for embedding in small devices.

- Mass Production Capability: MEMS processes are similar to semiconductor processes, allowing large-scale manufacturing and cost reduction.

- Low Power Consumption: Micro-mechanical designs reduce energy usage, suitable for portable or smart devices.

Advantages of High-Precision Pressure Sensors

High precision is a core advantage of Micro pressure sensors. In medical devices, aerospace, and high-end industrial control, measurement precision often determines reliability and safety. For instance, in ventilators, pressure errors directly affect patient breathing support; in drones, pressure measurement errors can destabilize flight; in industrial automation, high-precision pressure data ensures stable production processes.

Design and Innovation of Miniature Pressure Sensors

The miniaturization of Micro pressure sensors involves more than just reducing size; it also requires optimizing the entire system design. Key innovations include material improvements, structural optimization, packaging technology, and integrated signal processing. Advanced silicon-based or composite materials increase sensitivity and durability, while micro-mechanical structure design enhances pressure response accuracy. Specialized packaging ensures environmental adaptability and long-term stability, and integrated signal processing enables intelligent control. These innovations allow Micro pressure sensors to be compact yet highly reliable, meeting the needs of modern high-end devices.

Applications of Micro Pressure Sensors

Medical Devices

In healthcare, Micro pressure sensors are critical for precise pressure monitoring. They are used in ventilators to monitor airway pressure, ensuring patient safety; in blood pressure monitors for continuous, high-precision measurement; and in extracorporeal circulation equipment to track blood flow pressure, maintaining operational safety.

Automotive Systems

In the automotive industry, Micro pressure sensors are widely applied in tire pressure monitoring systems (TPMS), engine pressure control, and fuel injection systems. Their high precision and fast response allow vehicles to operate safely, efficiently, and intelligently.

Industrial Automation

Micro pressure sensors play a vital role in industrial production. They monitor pneumatic systems, control hydraulic pressures, and stabilize process flows. By providing reliable, high-precision pressure data, these sensors enhance production efficiency and reduce equipment failure rates.

Aerospace Applications

In aerospace, the importance of Micro pressure sensors is undeniable. Aircraft encounter complex and rapidly changing air pressure conditions at high altitudes. Traditional sensors cannot respond quickly enough, whereas Micro pressure sensors provide real-time, precise pressure measurements that allow flight control systems to adjust aircraft posture and propulsion dynamically. For drones, they enable accurate altitude control and stable flight in challenging environments.

Smart Devices

With the rise of IoT and smart devices, Micro pressure sensors have entered everyday applications. In smart homes, they monitor indoor air pressure, supporting ventilation and purification systems. In wearables, they track respiratory rate, blood pressure, and activity intensity, enabling comprehensive health management. The miniaturization, low power consumption, and high precision of these sensors allow smart devices to perform richer functions in smaller packages while extending battery life and improving user experience.

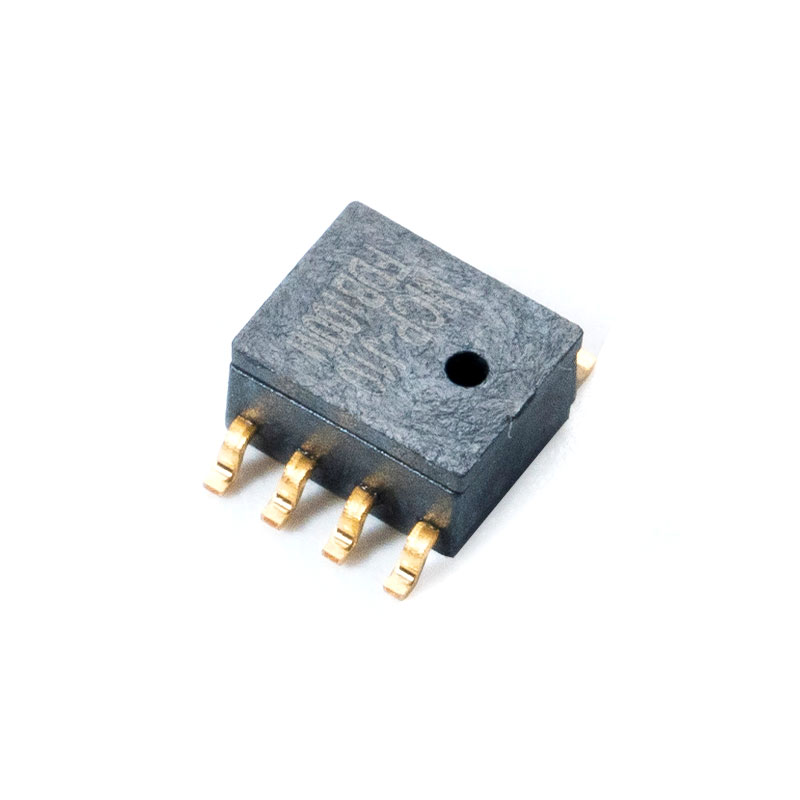

Technical Advantages of Micro Pressure Sensors

The core competitiveness of Micro pressure sensors lies in their technical strengths. High precision ensures reliable data, crucial for healthcare, drones, and industrial control. Miniaturization and lightweight design allow easy integration and low power consumption. Fast response enables systems to adjust in real time, improving efficiency and safety. Advanced materials and micro-fabrication techniques enhance durability and stability in extreme conditions, making these sensors suitable for both laboratory research and practical industrial applications.

Future Trends of Micro Pressure Sensors

Looking ahead, Micro pressure sensors will continue evolving toward higher precision, smaller size, and greater intelligence. IoT, AI, and wearable devices will expand their applications in smart homes, healthcare, and transportation. Miniaturization, low power consumption, and integration will be the core development goals.

New materials and advanced micro-fabrication techniques are being explored to further enhance sensitivity and durability. Integration with data processing chips and wireless modules will increase their role in intelligent applications. For instance, future wearable medical devices may use embedded Micro pressure sensors to monitor multiple physiological indicators in real time and provide personalized health recommendations via cloud analysis.

Additionally, their applications in environmental monitoring and energy optimization are promising. By measuring pressure and fluid flow, they can improve system efficiency, reduce energy consumption, and provide high-precision data for environmental research, highlighting their versatility and role in sustainable development.

Conclusion: Why Micro Pressure Sensors Are Indispensable

In conclusion, Micro pressure sensors are essential in modern technology. They ensure patient safety in medical devices, enable high-precision control in automotive, aerospace, and industrial systems, and facilitate intelligent operation in smart devices. Their miniaturization, high precision, fast response, low power consumption, and ease of integration make them a foundational component in advanced technology.

As materials science, micro-fabrication, and intelligent applications continue to evolve, Micro pressure sensors will expand into new fields, achieving higher precision, intelligence, and energy efficiency. In healthcare, industry, aerospace, and smart living, they not only witness technological progress but actively drive innovation. Micro pressure sensors serve as the microscopic eyes and nerves of modern technology, supporting countless devices to operate intelligently, efficiently, and reliably, and their future holds limitless possibilities.

Recommended Articles

English

English Français

Français 中文简体

中文简体