Differential Pressure Sensors: Driving Precision in Modern Engineering Applications

Date:2025-11-12

The Fundamental Role of Differential Pressure Sensing

At the heart of countless industrial and technological processes lies the need to measure and control pressure differences. A differential pressure sensor is a specialized device designed to measure the difference in pressure between two points. This seemingly simple function is the cornerstone of complex operations across diverse fields, from ensuring the safety of HVAC systems in large buildings to monitoring the efficiency of filtration systems in pharmaceutical manufacturing. Unlike absolute or gauge pressure sensors, which measure pressure relative to a vacuum or atmospheric pressure, respectively, differential sensors focus on the variance between two specific ports. This capability is critical for applications involving flow rate, liquid level in closed tanks, and filter condition monitoring. The precision offered by these sensors enables systems to operate at peak efficiency, reduces energy consumption, and prevents potential equipment failure, making them indispensable in the modern engineering landscape.

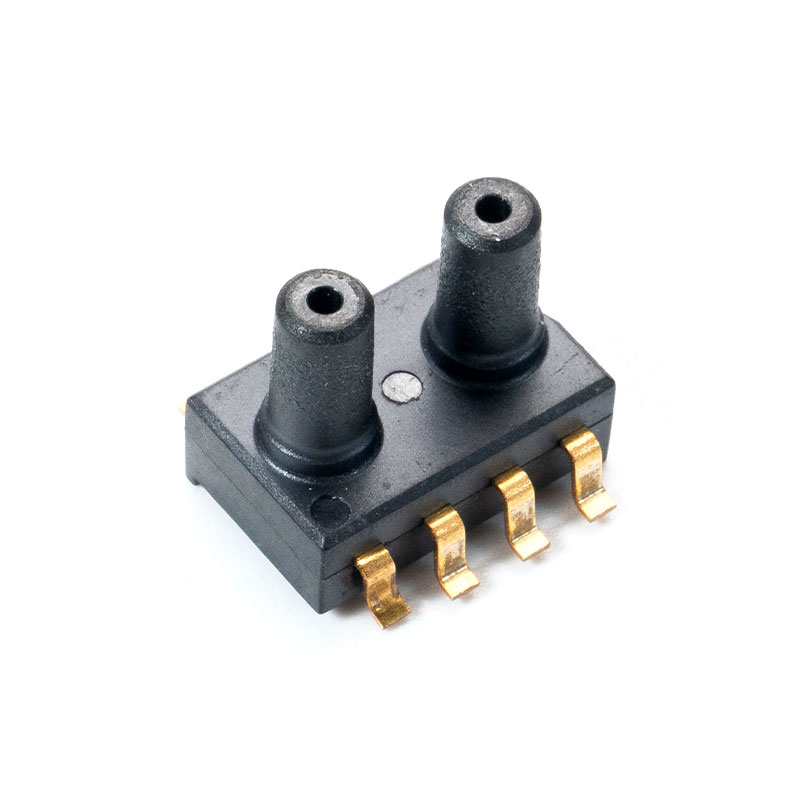

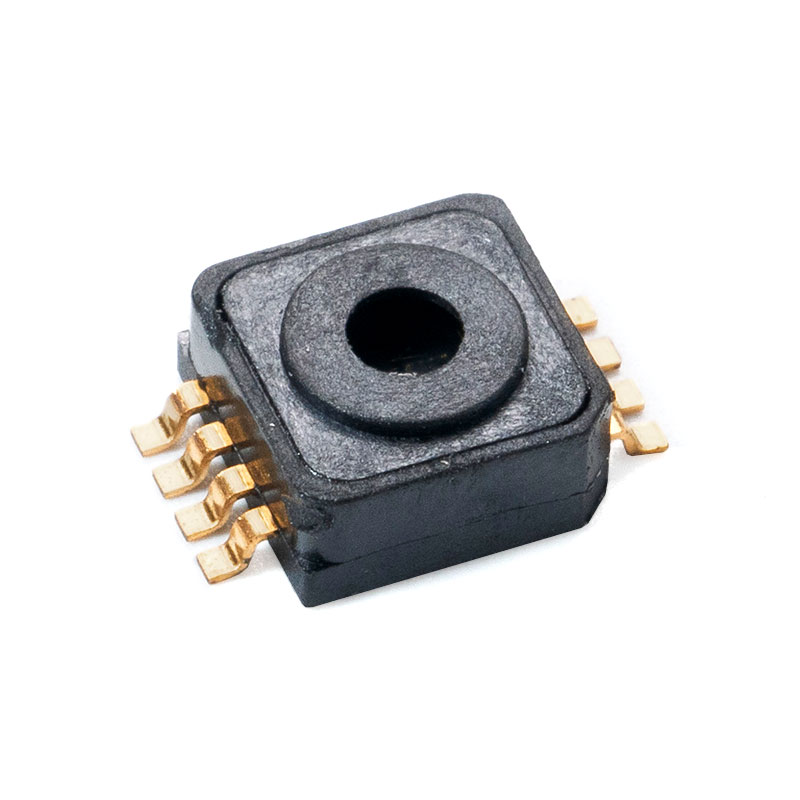

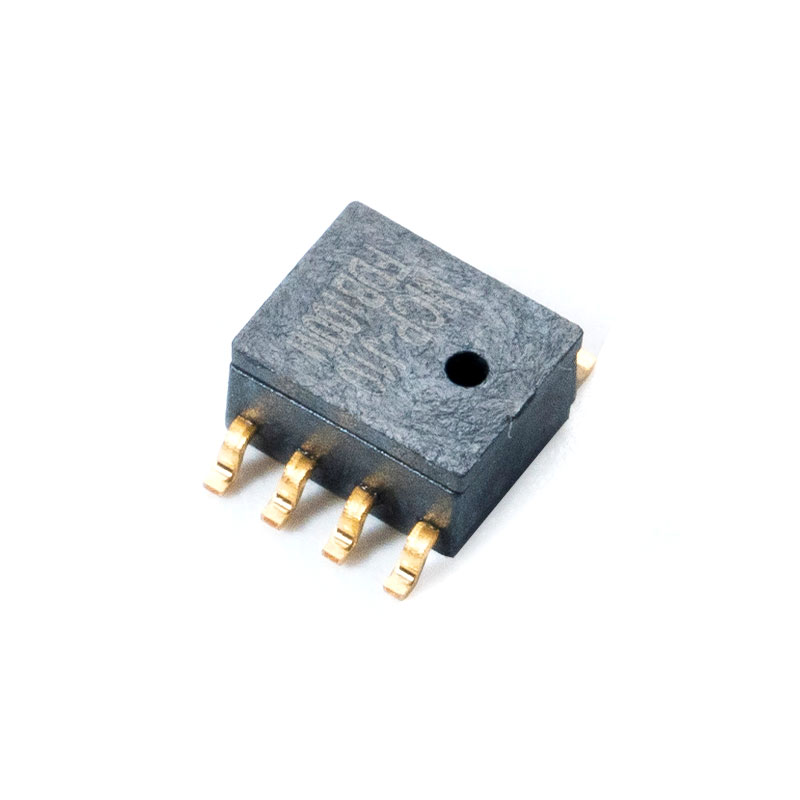

MCP7XXXDP, MCPV7XXXDP Differential pressure sensor

Key Applications and Technical Selection

The versatility of differential pressure sensors is demonstrated by their wide-ranging applications. Understanding these use-cases is the first step in appreciating their importance and guides the selection process for engineers.

Monitoring Critical Systems

One of the most vital roles of these sensors is in the continuous monitoring of system health and safety. They act as the first line of defense against operational failures.

Ensuring Cleanroom and HVAC Efficiency

In environments where air purity is paramount, such as pharmaceutical cleanrooms, semiconductor fabrication facilities, and hospital operating theaters, maintaining a specific pressure differential is non-negotiable. A positive pressure differential prevents unfiltered air from entering the clean space, while a negative pressure in isolation rooms contains contaminants. differential pressure sensor for cleanroom monitoring is a critical application where sensors provide real-time data to building management systems, triggering alarms if the pressure deviates from the setpoint. This continuous monitoring ensures compliance with stringent regulatory standards and protects both products and personnel. Compared to simple pressure switches, a continuous-output sensor provides trend data that can be used for predictive maintenance, identifying gradual filter clogging before it becomes a critical issue.

Safeguarding Industrial Processes

Beyond air systems, these sensors are crucial for liquid-based processes. They are extensively used to monitor the condition of filters in hydraulic systems, cooling water loops, and fuel lines. As a filter collects particulate matter, the pressure drop across it increases. A differential pressure sensor accurately measures this drop, signaling when the filter requires cleaning or replacement. This prevents unexpected downtime, protects downstream equipment from damage caused by bypassed contaminants, and optimizes maintenance schedules. The alternative—replacing filters on a fixed time schedule—is often wasteful and can lead to either premature replacement or, worse, a clogged filter causing a system shutdown.

Selecting the Right Sensor for Your Application

Choosing the appropriate differential pressure sensor is not a one-size-fits-all process. It requires a careful analysis of the application's specific demands to ensure accuracy, reliability, and longevity.

Understanding Performance Specifications

Key specifications must be evaluated to match the sensor to the task. These include:

- Pressure Range: The maximum differential pressure the sensor is designed to measure. Selecting a range that encompasses the expected operating pressures, including potential spikes, is crucial.

- Accuracy: Often expressed as a percentage of full-scale output, this defines how close the sensor's reading is to the true pressure value. High-precision applications demand high accuracy.

- Output Signal: Common outputs include analog (4-20 mA, 0-5 V, 0-10 V) and digital (I2C, SPI). The choice depends on the compatibility with the existing data acquisition or control system.

- Media Compatibility: The wetted materials of the sensor (those in contact with the medium being measured) must be compatible with the fluid or gas to avoid corrosion or degradation.

For instance, an engineer searching for a low differential pressure sensor for HVAC would prioritize a sensor with a very low pressure range (e.g., 0-1 inch of water column), high accuracy at that low range, and excellent long-term stability, as these systems require consistent performance over many years with minimal drift.

Comparing Sensor Technologies

Different sensing technologies offer distinct advantages and limitations. The two most prevalent types are capacitive and piezoresistive sensors.

Capacitive sensors measure pressure by detecting the change in capacitance between a diaphragm and a fixed electrode. When pressure deflects the diaphragm, the capacitance changes, and this change is converted into an electrical signal. Piezoresistive sensors use strain gauges bonded to a diaphragm; the pressure-induced strain changes the electrical resistance of the gauges, which is then measured. The following table outlines the key differences:

| Feature | Capacitive Sensing | Piezoresistive Sensing |

|---|---|---|

| Sensitivity | Generally higher sensitivity, making them suitable for very low pressure applications. | Good sensitivity, but typically less than capacitive for very low ranges. |

| Stability | Excellent long-term stability and low drift. | Good stability, but can be more susceptible to temperature-induced drift. |

| Robustness | Can be more sensitive to overload conditions and shock. | Generally more robust and able to withstand higher overpressures. |

| Cost | Often higher cost due to complex construction. | Typically more cost-effective for standard industrial ranges. |

Therefore, a project requiring a high accuracy dp sensor for energy audit would likely benefit from the stability and sensitivity of a capacitive sensor to detect minute pressure changes that correlate to energy losses. Conversely, a rugged differential pressure transmitter for industrial filtration might be better served by a robust piezoresistive model that can handle pressure spikes and a harsh environment.

Installation and Long-Term Reliability

The best sensor will underperform if installed incorrectly. Proper installation and a focus on long-term health are critical for obtaining reliable data.

Best Practices for Installation

Installation errors are a common source of measurement inaccuracy. Attention to detail during this phase pays significant dividends over the sensor's lifecycle. Key considerations include:

- Orientation: Many sensors are sensitive to mounting position. For liquid service, ensuring that any air bubbles can vent or that the sensor is not mounted in a way that allows condensate to pool in the impulse lines is vital.

- Impulse Lines: The tubing that connects the process to the sensor must be correctly sized and routed. Long, small-diameter lines can introduce significant lag and damping in the measurement. Lines should be sloped to prevent trapping gas (in liquid applications) or liquid (in gas applications).

- Pulsation Damping: In systems with significant pressure pulsations (e.g., near pumps), snubbers or other damping devices may be required to protect the sensor and provide a stable reading.

For someone looking for guidance on a differential pressure sensor installation guide, understanding these principles is the foundation. It ensures that the sensor's inherent accuracy is not compromised by the installation.

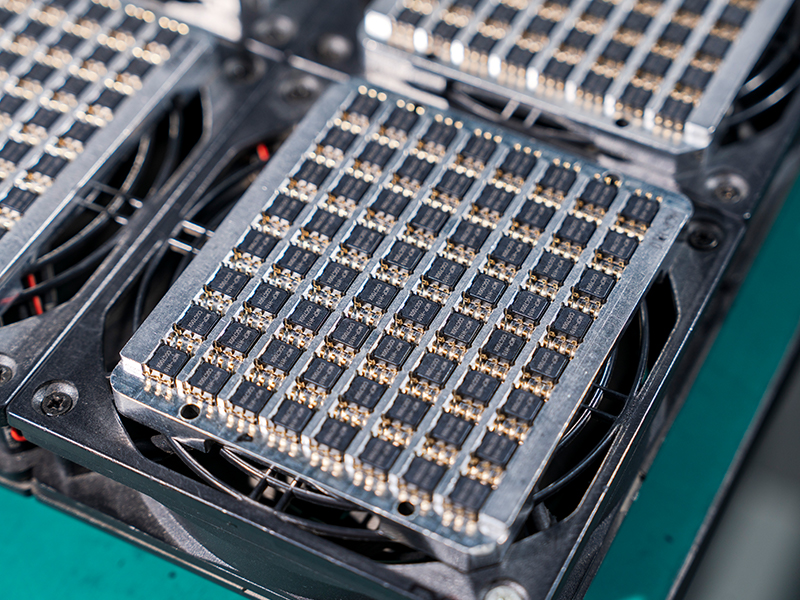

Ensuring Continuous Performance

Once installed, the work is not over. To maintain accuracy over years of service, a proactive approach to maintenance is essential. This includes regular calibration against a known standard to correct for any signal drift. It also involves routine checks of the impulse lines for blockages, leaks, or condensation. For sensors in dirty environments, a preventative cleaning schedule for the pressure ports may be necessary. By integrating these practices, the differential pressure sensor remains a reliable source of critical data, supporting system efficiency, safety, and operational intelligence long after the initial installation is complete.

Recommended Articles

English

English Français

Français 中文简体

中文简体