Micro Pressure Sensor: Revolutionizing Precision Monitoring Across Industries

Date:2025-11-12

- 1 Introduction

- 2 Overview of Micro Pressure Sensors

- 3 Key Technical Specifications

- 4 Major Application Scenarios

- 5 Technological Innovations and Product Trends

- 6 Selection Guide for Micro Pressure Sensors

- 7 Sensor Selection Comparison Table

- 8 Market Outlook and Development Trends

- 9 Case Studies and Successful Applications

- 10 Conclusion

Introduction

In today's era of precision engineering and smart devices, micro pressure sensors have become an essential component across multiple industries. From healthcare to automotive, and from wearable electronics to industrial automation, these sensors provide accurate pressure measurements in compact and efficient packages.

The importance of micro pressure sensors lies not only in their ability to monitor pressure with high precision but also in their adaptability to constrained spaces and dynamic environments. Their small form factor allows integration into devices where traditional sensors would be impractical.

Overview of Micro Pressure Sensors

Definition and Core Function

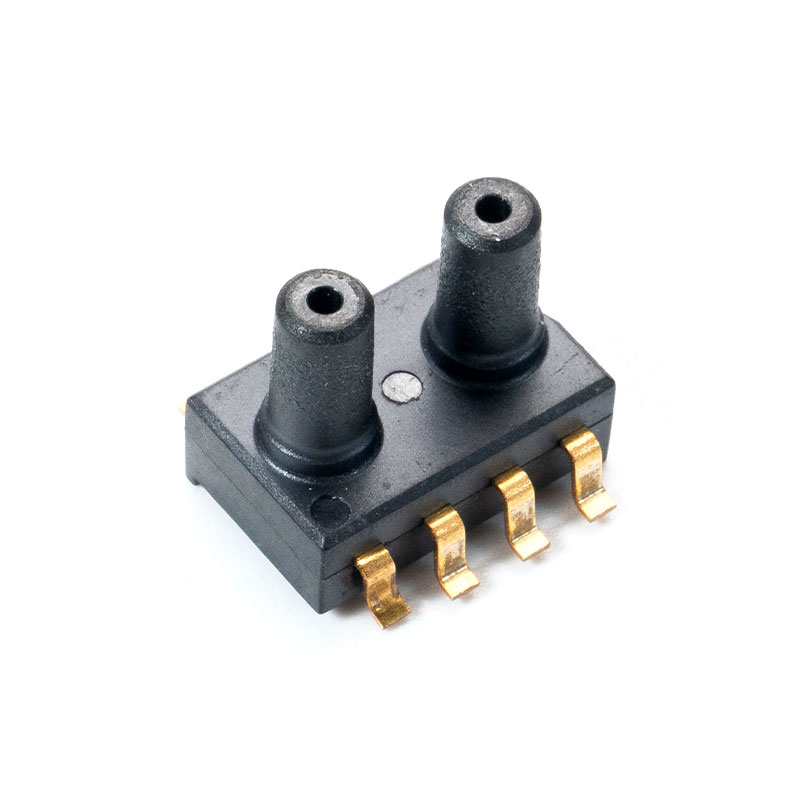

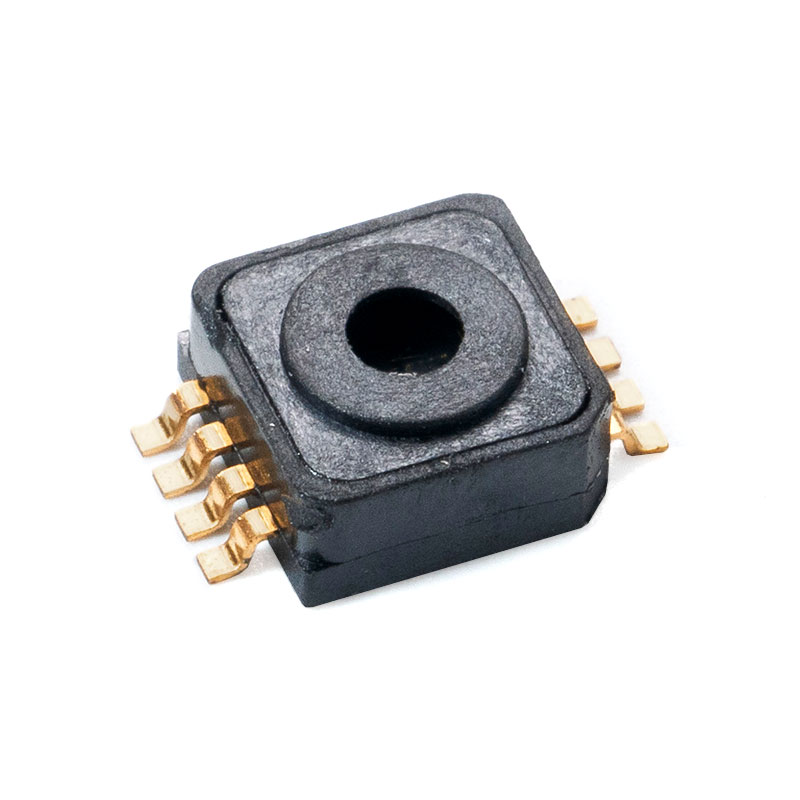

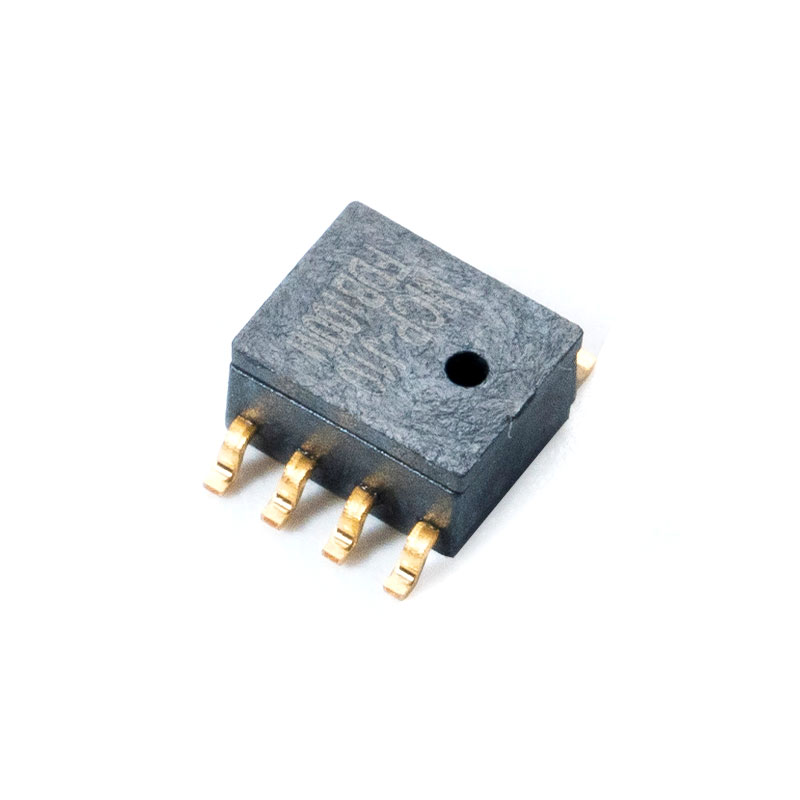

A micro pressure sensor is a device designed to measure pressure at very small scales, offering high precision and rapid response. Unlike conventional pressure sensors, micro pressure sensors are compact, lightweight, and capable of integrating into space-constrained applications. They are commonly used to measure absolute pressure, differential pressure, or gauge pressure depending on the system requirements.

Technology Types

Micro pressure sensors can be categorized into several major types based on their sensing mechanisms:

- MEMS-based Piezoresistive Sensors – Convert mechanical stress into resistance changes; widely used for their reliability and compact size.

- Capacitive Sensors – Detect pressure changes through variations in capacitance; known for high sensitivity and stability.

- Piezoelectric Sensors – Generate voltage in response to applied pressure; suitable for dynamic pressure measurements.

Each technology offers distinct advantages and trade-offs regarding sensitivity, accuracy, power consumption, and cost, making the selection dependent on the specific application.

Historical Development

The evolution of micro pressure sensors has been driven by the demand for miniaturization and higher performance. Early pressure sensors were relatively large and suitable only for industrial processes. The advent of MEMS technology enabled dramatic size reduction while maintaining high accuracy. Today, micro pressure sensors are a key enabling technology in areas ranging from medical devices and wearable electronics to automotive and aerospace systems.

Key Technical Specifications

Understanding the technical specifications of a micro pressure sensor is crucial for selecting the right device for a specific application. The main parameters to consider include:

-

Sensitivity

Sensitivity refers to the sensor's ability to detect small changes in pressure. Higher sensitivity ensures precise measurement even at low pressure levels, which is critical for applications such as medical monitoring and wearable devices. -

Accuracy and Linearity

Accuracy determines how close the sensor's output is to the true pressure value, while linearity measures the proportionality of output across the measurement range. High accuracy and linearity are essential for industrial control and automotive systems. -

Response Time

Response time indicates how quickly the sensor reacts to pressure changes. Applications requiring real-time monitoring, such as engine control or respiratory devices, demand sensors with minimal response time. -

Operating Pressure and Temperature Range

Micro pressure sensors are designed to operate under specific pressure and temperature conditions. Ensuring the sensor's range matches the application environment is critical for long-term reliability. -

Size and Packaging

Compact dimensions allow integration into constrained spaces. The sensor's form factor affects not only its application possibilities but also its sensitivity and durability.

Product Size and Performance Comparison

| Size Type | Pressure Range | Sensitivity | Response Time | Typical Applications |

|---|---|---|---|---|

| Small (≤3×3×1 mm) | 0–50 kPa | High | 1 ms | Wearable devices, miniature medical instruments |

| Medium (4×4×1.2 mm) | 0–100 kPa | Medium-High | 0.8 ms | Industrial monitoring, smart home systems |

| Large (5×5×1.5 mm) | 0–500 kPa | Medium | 0.5 ms | Automotive engines, aerospace systems |

Notes:

- This table emphasizes sensor selection based on size, which often determines compatibility with specific devices.

- Smaller sensors usually offer higher sensitivity and rapid response but are limited in maximum pressure range.

- Larger sensors can handle higher pressure ranges and harsh environments but occupy more space.

Major Application Scenarios

1. Healthcare Industry

In the medical field, micro pressure sensors play a crucial role in devices such as ventilators, blood pressure monitors, and minimally invasive surgical instruments. High precision, rapid response, and low power consumption are essential to ensure patient safety and reliable measurements.

2. Wearable Electronics

Wearable devices, including smartwatches, fitness trackers, and smart clothing, rely on flexible micro pressure sensors to monitor physiological parameters such as respiration, heart rate, and movement. The small form factor and durability are key requirements for continuous monitoring.

3. Industrial Automation and IoT

Micro pressure sensors are widely used in industrial automation for flow monitoring, HVAC systems, and smart factories. Their compact size allows integration into complex machinery, while high reliability ensures consistent operation in harsh environments.

4. Automotive and Aerospace

In automotive and aerospace applications, micro pressure sensors monitor engine performance, fuel systems, and environmental control systems. They must withstand high temperatures, vibrations, and long-term operational stress while maintaining precise measurements.

Application Scenarios Table

| Industry | Typical Applications | Core Requirements |

|---|---|---|

| Healthcare | Ventilators, Blood Pressure Monitors | High accuracy, fast response, low power consumption |

| Wearable Electronics | Fitness trackers, Smart clothing | Flexible, miniature, durable |

| Industrial | Flow monitoring, HVAC systems | High reliability, wide pressure range |

| Automotive | Engine monitoring, Fuel system control | High temperature tolerance, vibration resistance, long-term stability |

Technological Innovations and Product Trends

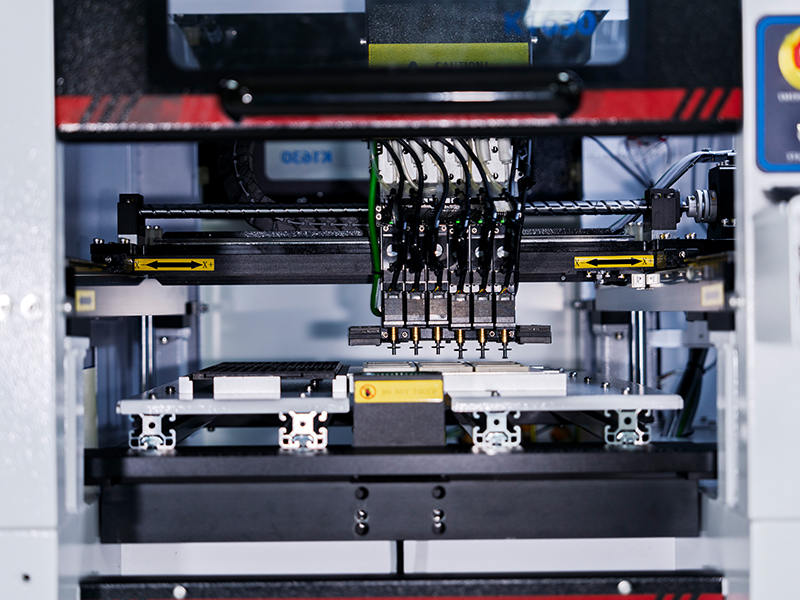

The micro pressure sensor industry is rapidly evolving, driven by advances in materials, fabrication processes, and system integration. Key innovations and trends include:

-

MEMS Technology Advancements

MEMS (Micro-Electro-Mechanical Systems) technology continues to revolutionize micro pressure sensors by enabling smaller sizes, higher sensitivity, and lower power consumption. MEMS fabrication techniques allow precise control of diaphragm thickness and geometry, improving sensor performance in compact packages. -

Flexible and Wearable Integration

Flexible materials and innovative packaging solutions are enabling micro pressure sensors to be embedded into wearable devices and flexible electronics. This trend allows continuous health monitoring, sports tracking, and personalized healthcare applications with minimal user intrusion. -

Low-Power and Wireless Sensors

With the rise of IoT (Internet of Things) and battery-operated devices, low-power micro pressure sensors are becoming critical. Innovations in energy-efficient designs and wireless data transmission allow sensors to operate for extended periods without frequent battery replacement. -

AI and Data Analytics Integration

The integration of artificial intelligence and advanced data analytics with micro pressure sensors is creating smarter monitoring systems. Predictive maintenance in industrial machinery can be achieved by analyzing pressure fluctuations, while wearable sensors can provide personalized health insights based on continuous pressure data. -

Miniaturization and Multi-Function Sensors

There is a clear trend toward combining multiple sensing capabilities into a single compact device. Sensors that measure pressure, temperature, and even flow simultaneously are increasingly in demand for industrial, medical, and consumer electronics applications.

Selection Guide for Micro Pressure Sensors

Selecting the right micro pressure sensor for a specific application requires careful consideration of multiple factors:

-

Measurement Range

Choose a sensor that covers the expected pressure range without exceeding its limits. Selecting a sensor with a wider range than necessary may reduce sensitivity, while a narrower range risks saturation under peak pressures. -

Response Time and Sensitivity

Applications that require real-time monitoring, such as engine control or respiratory devices, demand fast response times. Sensitivity should match the resolution requirements of the system to ensure accurate readings. -

Packaging and Installation

The sensor's physical dimensions, form factor, and mounting options must suit the device or system. Compact or flexible packaging is essential for wearable devices and confined spaces. -

Environmental Conditions

Consider temperature range, humidity, vibration, and potential exposure to chemicals. Sensors designed for harsh conditions should be robust and reliable over the intended operational lifespan. -

Application-Specific Requirements

Evaluate additional criteria such as power consumption, wireless communication capability, and integration with existing electronics or data systems.

Sensor Selection Comparison Table

| Selection Factor | Parameter Requirement | Recommended Application |

|---|---|---|

| Measurement Range | 0–50 kPa | Medical devices, wearable sensors |

| Response Time | <1 ms | Industrial rapid detection |

| Package Size | ≤5 mm | Miniature electronics, wearables |

| Temperature Tolerance | -40–85°C | Automotive, aerospace |

| Power Consumption | Low | IoT, battery-powered systems |

Market Outlook and Development Trends

The micro pressure sensor market has witnessed rapid growth in recent years and is projected to continue expanding due to increasing demand in healthcare, automotive, industrial, and consumer electronics sectors.

-

Global Market Growth

The global market is driven by smart devices, IoT applications, and precision industrial automation. Rising adoption in medical monitoring devices and wearable electronics further fuels demand. -

Emerging Application Areas

- Smart Cities: Environmental monitoring and intelligent building management.

- Home Automation: HVAC, water flow, and smart appliances.

- Advanced Healthcare: Continuous patient monitoring and personalized medical devices.

-

Technological Development Directions

Future micro pressure sensors will focus on higher precision, energy efficiency, wireless/IoT integration, and multi-functionality. -

Competitive Landscape

The market is competitive, with multiple players investing in R&D. Innovations in flexible, low-power, and high-accuracy sensors provide strategic advantages.

Case Studies and Successful Applications

1. Medical Devices

Micro pressure sensors in ventilators allow precise airflow and pressure control, improving patient safety. Blood pressure monitors and surgical instruments benefit from miniature, accurate sensors.

2. Wearable Health and Fitness Devices

Smartwatches and fitness trackers use these sensors to monitor heart rate, respiration, and movement, providing personalized health insights.

3. Industrial Automation and IoT

Sensors monitor fluid flow, air pressure, and environmental conditions in smart factories and HVAC systems, enhancing efficiency and safety.

4. Automotive and Aerospace

Sensors monitor fuel, oil pressure, and cabin conditions, improving performance, reliability, and safety in automotive and aerospace systems.

Conclusion

Micro pressure sensors have emerged as indispensable components in modern technology, offering compact size, high accuracy, and rapid response for a wide range of applications. Technological advancements such as MEMS fabrication, flexible materials, low-power designs, and wireless integration continue to expand possibilities. Emerging trends such as multi-function sensing, AI-assisted analytics, and IoT connectivity are driving further innovation.

Recommended Articles

English

English Français

Français 中文简体

中文简体