How Do Pressure Sensors Power Modern Vehicles?

Date:2025-11-12

- 1 The Unsung Heroes: Why Automotive Pressure Sensors Are Indispensable

- 2 A Deep Dive into Key Applications: Matching Sensors to Vehicle Systems

- 2.1 Keeping You Safe: Tire Pressure Monitoring Systems (TPMS)

- 2.2 Ensuring Cabin Comfort: HVAC and Air Conditioning Control

- 2.3 Monitoring the Heartbeat: Engine and Powertrain Health

- 2.4 Adapting to the Environment: Altitude and Air Density

- 2.5 Withstanding Extreme Heat: In-Engine and Exhaust Monitoring

- 3 The Broader Sensor Ecosystem: Lessons from Other Industries

- 4 Conclusion: Choosing the Right Partner for Automotive Sensing Excellence

- 5 FAQ

- 5.1 What is the most common type of pressure sensor used in cars today?

- 5.2 How do I know if my car's tire pressure sensor is bad?

- 5.3 Can a bad oil pressure sensor cause engine damage?

- 5.4 What's the difference between a MAP sensor and a barometric pressure sensor?

- 5.5 Why are pressure sensors so important for electric vehicles (EVs)?

The Unsung Heroes: Why Automotive Pressure Sensors Are Indispensable

Modern vehicles are marvels of engineering, relying on a complex network of electronic control units (ECUs) to manage everything from engine performance to passenger comfort. At the heart of this network are sensors, and among them, pressure sensors are the unsung heroes. These tiny yet powerful components continuously measure critical pressure variables, converting physical force into electrical signals that the vehicle's computer can interpret. This data is the lifeblood of active safety systems, fuel efficiency optimization, emissions control, and the seamless driving experience we often take for granted. The evolution from simple mechanical gauges to highly intelligent, silicon-based MEMS (Micro-Electro-Mechanical Systems) sensors has been transformative, enabling unprecedented levels of precision, reliability, and integration. As vehicles advance towards greater autonomy and electrification, the role of these sensors becomes even more critical, forming the foundational layer of data upon which smart automotive systems are built.

- Safety Foundation: Pressure sensors are integral to active safety systems like Tire Pressure Monitoring Systems (TPMS) and brake systems, providing real-time data to prevent accidents.

- Efficiency Engine: By optimizing air-fuel mixtures and monitoring system pressures, they directly contribute to better fuel economy and lower emissions.

- Comfort & Control: They enable automated climate control (HVAC) and a smooth, responsive driving experience by managing various hydraulic and pneumatic systems.

- Enabling Technology: The shift to MEMS technology has allowed for smaller, more durable, and cost-effective sensors, making their widespread use throughout the vehicle possible.

A Deep Dive into Key Applications: Matching Sensors to Vehicle Systems

The application of pressure sensors in an automobile is diverse, with each type meticulously designed for a specific task. Understanding these applications reveals the intricate balance of engineering required to create a safe, efficient, and comfortable vehicle. From the tires that touch the road to the air conditioning that cools the cabin, pressure sensors are constantly at work, ensuring every system operates within its ideal parameters. Let's explore these key applications in detail.

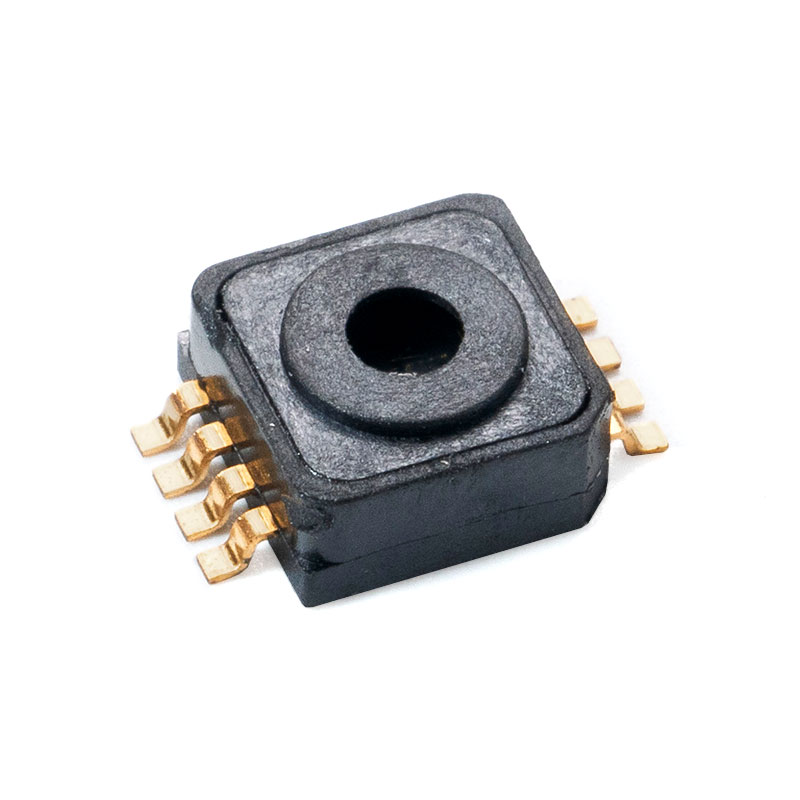

MCP-J20 Pressure sensor for automobiles

Keeping You Safe: Tire Pressure Monitoring Systems (TPMS)

Perhaps the most well-known application, TPMS is a mandatory safety feature in many regions. It constantly monitors the air pressure inside each tire, alerting the driver to significant under-inflation. This system is crucial because under-inflated tires can lead to tire failure, reduced braking performance, and poor fuel economy. The core of this system is a highly specialized sensor mounted inside the tire's valve stem or wheel assembly.

What Makes a Great automotive MEMS pressure sensor for TPMS?

The environment inside a tire is one of the most challenging for any electronic component. The sensor must withstand extreme temperature variations, from freezing winter roads to scorching summer asphalt, as well as constant vibration, moisture, and shocks from potholes. Therefore, selecting the right sensor is paramount for system reliability and longevity. This is why leading automotive brands and Tier-1 suppliers prioritize partnerships with established automotive MEMS pressure sensor manufacturers for TPMS systems that can guarantee performance under these harsh conditions.

- Low Power Consumption: Since the sensor is battery-powered and expected to last for the vehicle's lifetime (typically 5-10 years), ultra-low power design is non-negotiable.

- High Accuracy & Resolution: Must detect small pressure changes (e.g., a 1-2 PSI drop) to provide timely warnings.

- Robustness: Must be resistant to vibration, shock, and a wide operating temperature range (typically -40°C to +125°C).

- Miniaturization: The sensor must be compact and lightweight to avoid affecting wheel balance.

Ensuring Cabin Comfort: HVAC and Air Conditioning Control

Modern climate control systems are designed to be "set it and forget it," but this convenience is powered by sophisticated sensors. Pressure sensors play a dual role in the Heating, Ventilation, and Air Conditioning (HVAC) system. They monitor the pressure of the refrigerant in the A/C loop to optimize compressor performance and prevent damage, and they can also measure cabin air pressure to help manage air intake and circulation, particularly in vehicles with automatic air recirculation or multi-zone climate control.

The Need for Precision with a low pressure sensor for automotive HVAC

Refrigerant pressure in an A/C system is relatively low but critically important. An inaccurate reading can lead to poor cooling, increased compressor wear, and higher energy consumption. Similarly, subtle changes in cabin pressure are used to determine when to draw in fresh air versus recirculating interior air. This requires a sensor with high sensitivity and precision in a low-pressure range. Finding the right low pressure sensor for automotive** HVAC and cabin control** is key to achieving the high level of comfort and efficiency that consumers expect.

- Refrigerant Monitoring: Measures high and low side pressure to control the compressor clutch and protect the system from over- or under-pressure conditions.

- Cabin Pressure Management: Assists in controlling flaps and dampers for optimized air distribution and filtration.

- Temperature Compensation: The sensor must maintain accuracy across a wide range of ambient temperatures.

- Fast Response Time: Quickly reacts to changes in pressure (e.g., when the A/C is turned on) to ensure rapid system response.

Monitoring the Heartbeat: Engine and Powertrain Health

The engine is the heart of the vehicle, and pressure sensors are its vital sign monitors. From ensuring proper lubrication to optimizing combustion, these sensors provide the ECU with the data needed to run the engine efficiently, cleanly, and safely. While many sensors exist, the oil pressure sensor is one of the most critical for protecting the engine from catastrophic failure.

Gauging Engine Vital Signs with automotive oil pressure sensor Technology

The oil pressure sensor provides a direct reading of the oil pressure in the engine's lubrication system. Adequate oil pressure is essential to prevent metal-to-metal contact between moving parts. If the pressure drops too low, severe engine damage can occur in seconds. The sensor sends a signal to a dashboard warning light or gauge, providing the driver with an immediate alert to stop the engine. This simple function is a primary line of defense against one of the most costly types of engine failure.

- Critical Safety Alert: Triggers the oil pressure warning light on the dashboard when pressure falls below a safe threshold.

- Data for ECU: In some advanced systems, the ECU uses the actual pressure value to adjust engine performance or protect the engine under certain conditions.

- Robust Construction: Must withstand high temperatures, engine oil exposure, and significant vibration.

Industrial vs. Automotive: An automotive oil pressure sensor vs industrial pressure sensor comparison

While both measure pressure, the design priorities for an automotive sensor are vastly different from those of an industrial sensor. An automotive sensor is optimized for mass production, cost-effectiveness, and resilience to the unique environment of a vehicle. In contrast, an industrial sensor is often built for specific media compatibility, long-term stability in a fixed installation, and may prioritize different standards. This comparison highlights why a Pressure sensor for industrial is not a direct substitute for its automotive counterpart.

| Feature | Automotive Oil Pressure Sensor | Industrial Pressure Sensor |

| Primary Environment | High vibration, extreme temperature swings, space-constrained engine bay. | Often stable, but may involve corrosive media, high pressures, or outdoor elements. |

| Form Factor & Cost | Highly optimized for mass production, compact, and cost-sensitive. | Often larger, more robust, with a higher cost per unit, built for durability. |

| Key Certification | AEC-Q100 (Automotive Electronics Council reliability standard). | IP ratings (Ingress Protection), specific material or hazardous area certifications (e.g., ATEX). |

| Lifecycle & Volume | Designed for the vehicle's lifecycle (~15-20 years), produced in millions of units. | Designed for long-term serviceability, often produced in lower volumes. |

Adapting to the Environment: Altitude and Air Density

As a vehicle drives from sea level into the mountains, the density of the air changes significantly. This affects engine performance, as the engine needs the correct ratio of air to fuel for optimal combustion. A barometric pressure sensor measures the ambient atmospheric pressure, allowing the ECU to calculate the current altitude and adjust the fuel injection and ignition timing accordingly. This ensures consistent power delivery and fuel economy regardless of elevation.

How a barometric pressure sensor for automotive** Enables Smart Adjustments

The applications for a barometric sensor extend beyond simple altitude compensation. In modern vehicles, they are used for more complex functions. For instance, they can work with the HVAC system to help manage cabin pressure when driving through tunnels or at high altitudes. In electric vehicles (EVs), they can be part of the battery management system, helping to assess the cooling needs of the battery pack based on ambient pressure and temperature. The versatility of the barometric pressure sensor for automotive** altitude compensation applications** makes it a key component for refined vehicle control.

- Engine Optimization: Adjusts air-fuel mixture based on altitude to maintain optimal combustion and power output.

- EV Battery Management: Assists in thermal management systems for battery packs by providing environmental data.

- HVAC Enhancement: Works with other sensors to manage cabin pressure and air quality.

- Navigational Aid: Can be used in conjunction with GPS to improve altitude accuracy in navigation systems.

Withstanding Extreme Heat: In-Engine and Exhaust Monitoring

The push for greater engine efficiency and lower emissions is driving sensor technology into ever-hotter environments. Applications like gasoline direct injection (GDI), exhaust gas recirculation (EGR), and turbocharger boost control require sensors that can operate reliably at temperatures that would destroy standard electronics. This represents a significant challenge in material science and sensor design.

The Challenge of Finding a high temperature pressure sensor for automotive** Engine Monitoring Solutions

Standard automotive sensors are typically rated up to 125°C or 150°C. However, placing a sensor directly in the intake manifold of a turbocharged engine or in the EGR stream can expose it to temperatures exceeding 200°C. To meet this demand, sensor manufacturers are developing specialized solutions using high-temperature semiconductors (like Silicon-on-Insulator, SOI), ceramic substrates, and robust packaging. These advanced high temperature pressure sensor for automotive** engine monitoring solutions** are critical for enabling the next generation of downsized, turbocharged engines that meet stringent global emissions standards.

- GDI Pressure Sensing: Measuring fuel pressure directly in the rail at high temperatures and pressures.

- EGR Monitoring: Measuring the pressure of exhaust gases being recirculated back into the engine to reduce NOx emissions.

- Turbo Boost Control: Providing accurate pressure data for precise control of the turbocharger, improving responsiveness and efficiency.

- Advanced Materials: Utilizing SOI MEMS technology and ceramic packaging to ensure stability and longevity at extreme temperatures.

The Broader Sensor Ecosystem: Lessons from Other Industries

Automotive sensor technology does not evolve in a vacuum. Innovations and manufacturing techniques from other sectors, particularly consumer electronics and unmanned aerial vehicles (drones), heavily influence the automotive landscape. The cross-pollination of ideas and technologies accelerates development cycles and drives down costs, ultimately benefiting the end consumer.

Cross-Industry Synergies: What Can Automotive Learn from Drones and Consumer Electronics?

The massive scale and rapid innovation cycles in the consumer and drone markets create a perfect testing ground for sensor technologies that eventually find their way into cars. The core requirements—small size, low power, high performance, and low cost—are shared across these industries, creating a powerful synergy.

From the Skies: How Pressure sensor for drones** Tech Informs Automotive Altitude Sensing

Drones rely heavily on barometric pressure sensors for flight stabilization and altitude hold. They combine this data with accelerometers and GPS to maintain a steady hover. The sophisticated algorithms developed to filter out noise from propeller wash and wind gusts in drone applications are directly applicable to automotive scenarios, such as distinguishing between a change in altitude and a temporary pressure fluctuation from a passing truck, leading to more stable and reliable altitude compensation in vehicles.

- Advanced Filtering Algorithms: Drone sensor fusion techniques improve the accuracy of automotive barometric readings.

- High-Performance MEMS: The demand for lightweight and responsive sensors in drones pushes MEMS technology forward.

In Your Pocket: The Miniaturization Drive from Pressure sensor for consumer electronics

Every smartphone contains a barometric pressure sensor, used for everything from assisted GPS altitude to tracking the number of floors climbed in a fitness app. The incredible demand for these sensors—hundreds of millions per year—has been the single biggest driver of MEMS pressure sensor miniaturization and cost reduction. This economies-of-scale effect directly benefits the automotive industry, making it feasible to integrate multiple high-performance sensors throughout a vehicle at a competitive price point.

- Cost Reduction: Mass production for consumer electronics dramatically lowers the cost per sensor for automotive applications.

- Size and Integration: The push for ever-smaller sensors in wearables and phones enables more compact and integrated automotive sensor modules.

Conclusion: Choosing the Right Partner for Automotive Sensing Excellence

As vehicles transform into sophisticated, software-defined machines, the importance of the underlying physical hardware—the sensors—has never been greater. The data that powers advanced driver-assistance systems (ADAS), predictive maintenance, and hyper-efficient powertrains all begins with an accurate, reliable measurement. The future of automotive technology is one of deeper integration, where sensors will not just report data but will also perform local processing and communicate with each other, forming an intelligent nervous system for the vehicle.

The Future is Integrated and Intelligent

We are moving towards an era of multi-function sensors that combine pressure, temperature, and humidity sensing in a single package. This reduces complexity, saves space, and provides a richer data set for the vehicle's ECUs. The rise of vehicle-to-everything (V2X) communication will also rely on this foundational sensor data to create a complete picture of the vehicle's operating environment.

Why Expertise and Reliability Matter

In this landscape, a sensor is no longer a simple component; it is a critical piece of safety and performance infrastructure. This is why expertise in MEMS design, scientific production management, and rigorous testing are paramount. A partner with a deep understanding of the unique demands of the automotive environment—vibration, temperature extremes, and the need for AEC-Q100 reliability—is essential. As a specialist in the R&D, production, and sales of MEMS pressure sensors, the commitment is to consistently deliver high-performance, cost-effective sensing solutions that power the next generation of vehicles. Choosing a partner with this foundation of professional development and competitive pricing is the key to navigating the future of mobility.

FAQ

What is the most common type of pressure sensor used in cars today?

The most common type is the piezoresistive MEMS (Micro-Electro-Mechanical Systems) pressure sensor. This technology uses a silicon diaphragm with embedded piezoresistors. When pressure is applied, the diaphragm flexes, changing the resistance of the piezoresistors. This change is then converted into a voltage or digital signal. MEMS technology is favored for its small size, high accuracy, low cost, and excellent suitability for mass production, making it the standard for applications like TPMS, MAP sensors, and barometric sensors.

How do I know if my car's tire pressure sensor is bad?

A failing tire pressure sensor can manifest in several ways. The most obvious is a TPMS warning light that stays on, flashes, or displays an incorrect pressure reading even after you have inflated the tires to the correct level. Other signs include a warning light that only comes on when the car is first started but then goes off, or a system that cannot be retrained after a tire rotation. A professional diagnostic tool can read the sensor's ID and signal strength to confirm if a specific sensor has failed or has a weak battery.

Can a bad oil pressure sensor cause engine damage?

Yes, indirectly. The sensor itself doesn't cause damage, but a faulty sensor can fail to warn you of a genuine loss of oil pressure. If the actual oil pressure drops to zero due to a leak or pump failure and the sensor doesn't trigger the warning light on your dashboard, the engine can run without lubrication for even a short period. This leads to catastrophic friction between metal parts, resulting in seized pistons, damaged bearings, and a complete engine failure. Therefore, a functioning automotive oil pressure sensor is a critical safety device.

What's the difference between a MAP sensor and a barometric pressure sensor?

Both are pressure sensors, but they measure different things and serve different purposes. A MAP (Manifold Absolute Pressure) sensor measures the pressure inside the engine's intake manifold. This reading is vital for the ECU to calculate engine load and determine the correct amount of fuel to inject. A barometric pressure sensor measures the ambient atmospheric pressure outside the vehicle. The ECU uses this data primarily to compensate for changes in altitude, ensuring the air-fuel mixture remains optimal as you drive up or down mountains. Some advanced ECUs may use a single sensor that can function as both, switching roles based on operating conditions.

Why are pressure sensors so important for electric vehicles (EVs)?

While EVs don't have traditional engines with oil pressure, they rely heavily on pressure sensors for other critical systems. The most important application is in the battery thermal management system. Sensors monitor the pressure of the coolant loop to ensure the battery pack stays within its optimal temperature range, which is crucial for performance, longevity, and safety. They are also used in climate control (HVAC) systems, brake-by-wire systems, and in some cases, to monitor the pressure of the tire inflation systems that are often integrated with the EV's sophisticated energy management software.

Recommended Articles

English

English Français

Français 中文简体

中文简体