Precision in the Thin Air: Why Absolute Pressure Sensors Outperform Gauge Sensors in High-Altitude Environments

Date:2026-01-01

- 1 1. Reference Point Engineering: Absolute vs. Gauge Benchmarking

- 2 2. Micro-Electromechanical Systems (MEMS) in Critical Care

- 3 3. Performance in Extreme Conditions: Vacuum and Corrosion

- 4 4. IoT Integration and Digital Signal Integrity

- 5 5. MemsTech Manufacturing and Testing Excellence

- 6 Conclusion: The Only Standard for Elevation

- 7 Frequently Asked Questions (FAQ)

In aerospace, unmanned aerial vehicle (UAV) design, and high-altitude industrial monitoring, the accuracy of pressure measurement is non-negotiable. As elevation increases, atmospheric pressure drops non-linearly, creating a "measurement noise" that can compromise system safety. Founded in 2011 and situated in the Wuxi National Hi-tech District—China’s premier hub for IoT innovation—MemsTech has dedicated over a decade to the R&D of high-performance sensing solutions. Our expertise in MEMS technology allows us to address the unique challenges of barometric fluctuation through the advanced Absolute Pressure Sensor.

1. Reference Point Engineering: Absolute vs. Gauge Benchmarking

The core challenge of high-altitude sensing lies in the zero-reference stability. While a gauge pressure sensor measures the difference between the process pressure and the ever-changing ambient air, an absolute pressure sensor vs. gauge pressure sensor in altitude compensation reveals a fundamental divergence: the absolute sensor utilizes an internal, hermetically sealed vacuum as its constant zero point. This ensures that as a drone or aircraft ascends, the sensor's reading remains tied to a physical constant rather than a fluctuating atmospheric baseline, which can vary by as much as 12% per 1,000 meters of ascent.

| Technical Feature | Gauge Pressure Sensor | Absolute Pressure Sensor |

| Reference Pressure | Ambient Atmosphere (Variable) | Internal Vacuum (Fixed) |

| Altitude Error | High (Requires complex algorithms) | Near Zero (Inherent compensation) |

| Hermeticity | Vented to atmosphere | Fully sealed (MEMS cavity) |

| Application Suitability | Standard sea-level industrial tanks | Avionics, Altimeters, and Space Tech |

2. Micro-Electromechanical Systems (MEMS) in Critical Care

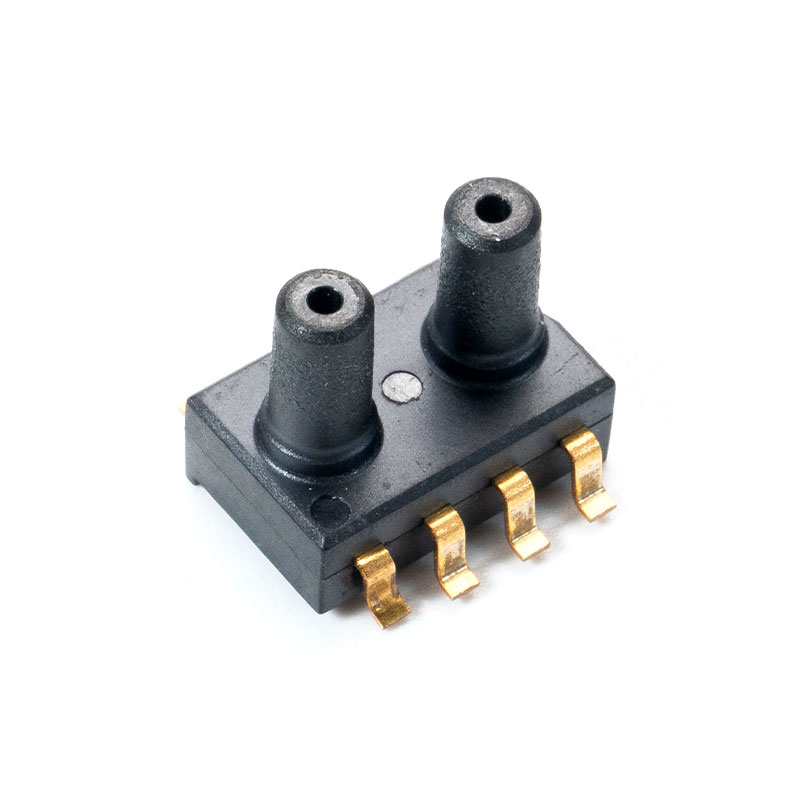

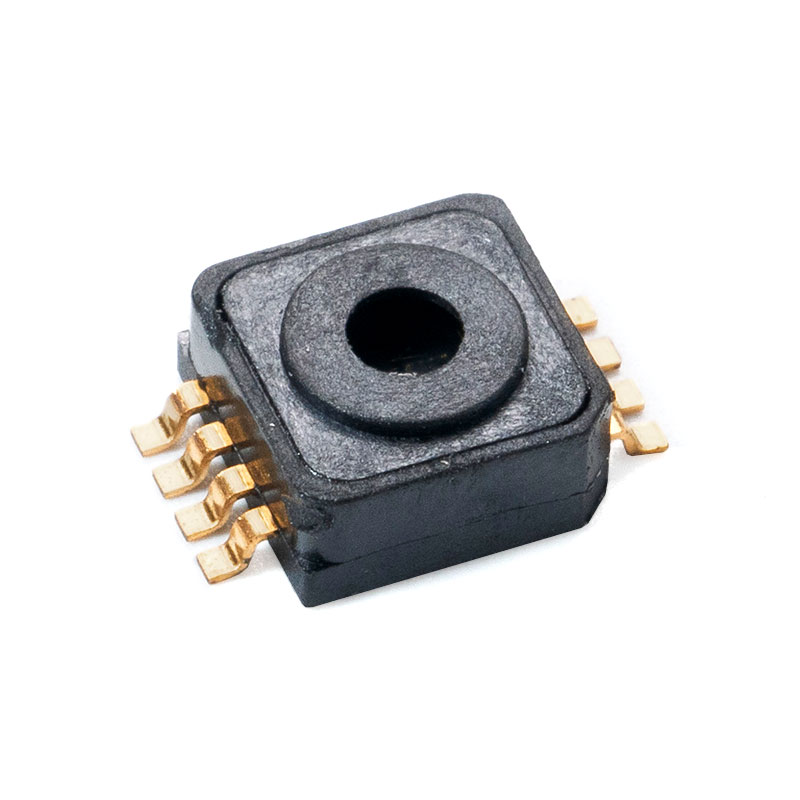

Miniaturization is a prerequisite for modern medical and portable technologies. In environments such as high-altitude clinics or emergency transport aircraft, a MEMS-based miniature absolute pressure sensor for medical devices provides the necessary sensitivity for respiratory monitoring without the bulk of traditional mechanical bellows. MemsTech utilizes precision silicon etching to create micro-scale diaphragms that respond to minute pressure changes in milliseconds, ensuring that ventilators and oxygen concentrators maintain consistent delivery regardless of the cabin's effective altitude.

According to the latest technical report by the International Organization for Standardization (ISO) regarding medical electrical equipment, the integration of MEMS-level sensing is now the benchmark for achieving the high-frequency sampling required in modern neonatal and critical care ventilation systems. This shift towards atomic-level precision ensures that medical professionals can rely on absolute data points in variable pressure environments.

3. Performance in Extreme Conditions: Vacuum and Corrosion

Industrial processes located in mountainous regions or specialized high-altitude labs require instrumentation that ignores the thin exterior air. Utilizing a high-accuracy absolute pressure sensor for industrial vacuum systems allows manufacturers to maintain consistent vacuum levels in semiconductor or pharmaceutical lines, independent of local barometric shifts. Furthermore, for outdoor chemical monitoring at high elevations, a corrosion-resistant absolute pressure sensor for chemical processing is vital. MemsTech employs specialized gel-filling and protective coatings to shield the sensitive MEMS die from oxidative stress and low-temperature condensation often found in alpine industrial zones.

4. IoT Integration and Digital Signal Integrity

The modernization of the "Wuxi National Hi-tech District" philosophy involves transitioning from analog signals to robust digital data. Selecting a digital absolute pressure sensor with I2C/SPI interface for IoT is critical for high-altitude remote monitoring where signal attenuation and electromagnetic interference (EMI) are prevalent. Digital communication ensures that the data reaching the cloud or the flight controller is identical to the data captured by the sensor diaphragm, enabling low-power, long-range sensing nodes for smart city and environmental research.

Recent market data from the 2024-2025 Global IoT Sensor Analysis by Mordor Intelligence indicates that digital interfaces like I2C and SPI have surpassed analog outputs in the industrial sector, now representing over 65% of new sensor deployments. This trend is driven by the need for multi-sensor fusion and real-time compensation in complex autonomous systems.

Source: Global Sensor Market - Growth, Trends, and Forecasts (2024-2029)

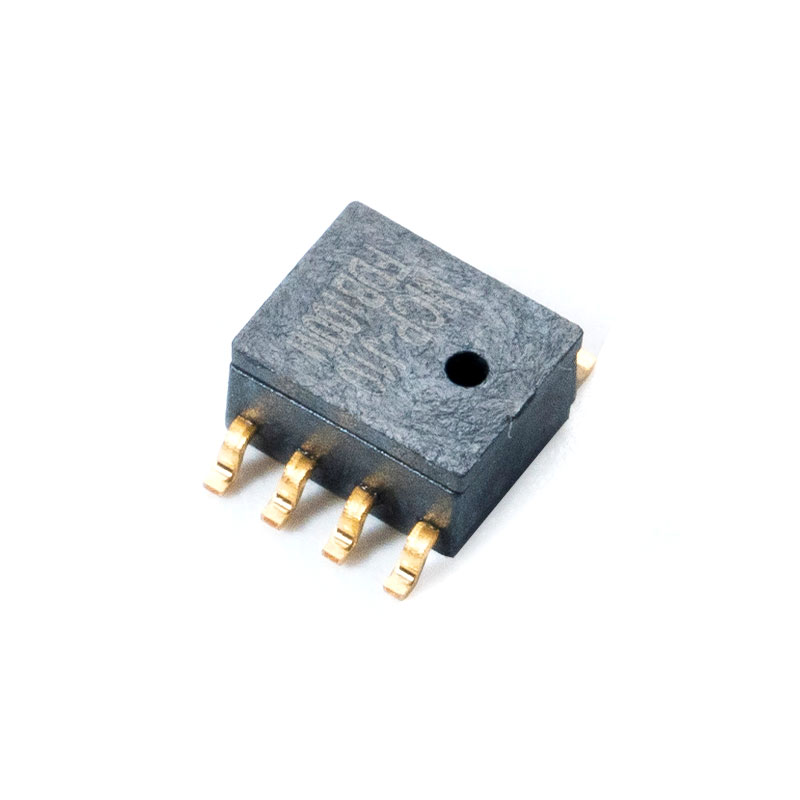

5. MemsTech Manufacturing and Testing Excellence

MemsTech prides itself on a rigorous lifecycle management process that includes:

- Professional Development: Leveraging high-tier MEMS fabrication facilities.

- Scientific Production Management: Ensuring every batch meets stringent automotive and medical standards.

- Rigorous Packaging and Testing: Simulating high-altitude and vacuum conditions to verify sensor calibration.

- Competitive Pricing: Delivering high-performance, cost-effective solutions for global B2B procurement.

Conclusion: The Only Standard for Elevation

For engineers and B2B buyers, the Absolute Pressure Sensor is not just an alternative; it is the only reliable standard for applications where the atmosphere is a variable. MemsTech continues to push the boundaries of MEMS technology, ensuring that our partners in medical, automotive, and consumer electronics sectors have the precision they need, even in the thinnest air.

Frequently Asked Questions (FAQ)

- Q1: Why can't I just use a gauge sensor and subtract the atmospheric pressure?

A: While possible via software, it introduces two sources of error and requires a second barometer. An absolute sensor provides a cleaner, faster hardware-level solution. - Q2: How does altitude affect the lifespan of a pressure sensor?

A: Standard sensors may suffer from seal fatigue. MemsTech’s absolute sensors use wafer-level bonding to ensure the vacuum reference remains hermetic for over a decade. - Q3: Are digital I2C sensors difficult to calibrate at high altitudes?

A: No, our digital sensors are factory-calibrated against a primary vacuum standard, meaning they provide accurate absolute data immediately upon integration. - Q4: Is the corrosion-resistant coating necessary for high-altitude drones?

A: Yes, as drones often pass through clouds or mist, condensation can lead to corrosion. Our gel-protected sensors are designed for these specific outdoor challenges. - Q5: What is the maximum altitude MemsTech sensors can measure?

A: Our sensors are designed to operate from deep vacuum up to standard atmospheric pressure, making them suitable for near-space applications and high-altitude avionics.

Recommended Articles

English

English Français

Français 中文简体

中文简体