MCP Pressure Sensor for Ventilators: What Are the Critical Requirements?

Date:2025-12-03

- 1 The Vital Role of Pressure Sensing in Modern Ventilator Systems

- 2 Understanding Ventilator Pressure Sensing Points

- 3 Key Specifications for Medical-Grade MCP Pressure Sensors

- 4 Ensuring Reliability and Safety in Critical Care

- 5 Compliance and Manufacturing Requirements

- 6 Disposable vs. Reusable Design Considerations

- 7 Ventilator Sensor Selection Checklist

- 8 FAQ

- 8.1 What is the typical lifespan requirement for MCP sensors in continuous-use ventilators?

- 8.2 How does condensation affect pressure sensor accuracy in ventilator circuits?

- 8.3 Can the same MCP sensor be used for both invasive and non-invasive ventilation?

- 8.4 What redundancy approaches are recommended for critical ventilator pressure monitoring?

- 8.5 How are MCP sensors validated for use with oxygen-rich environments?

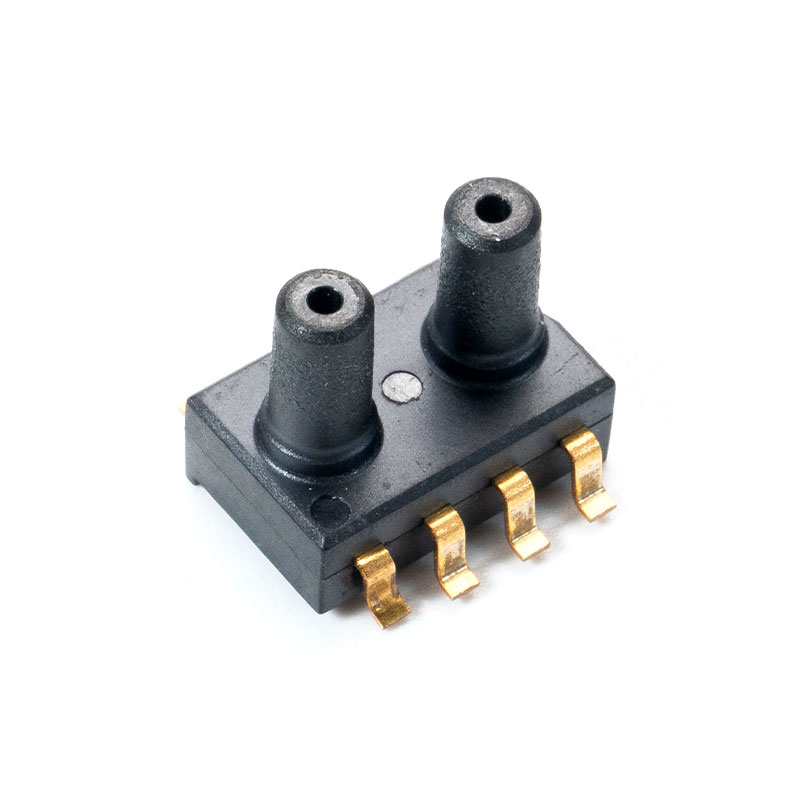

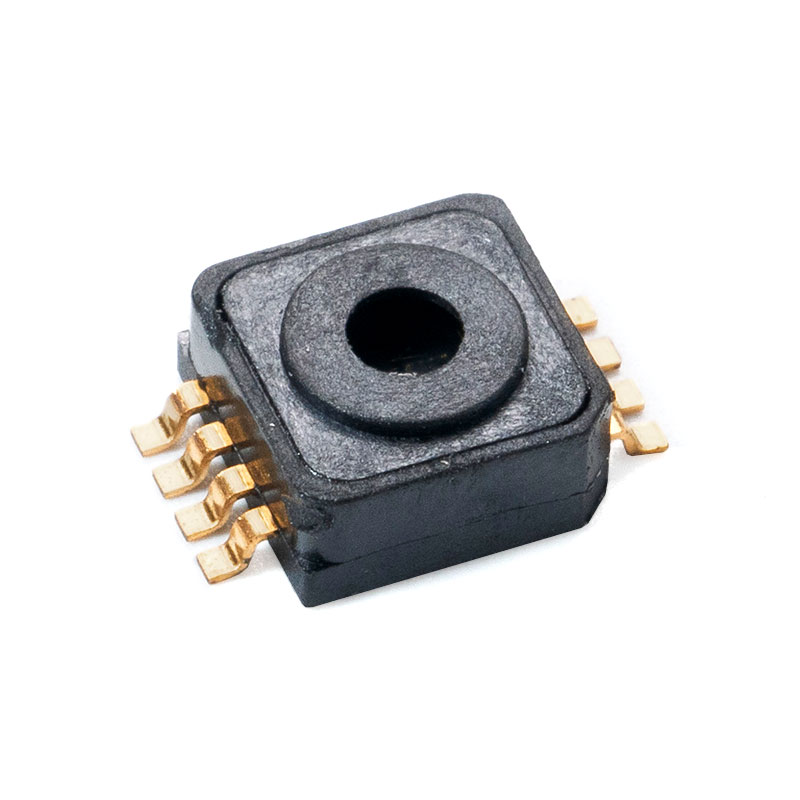

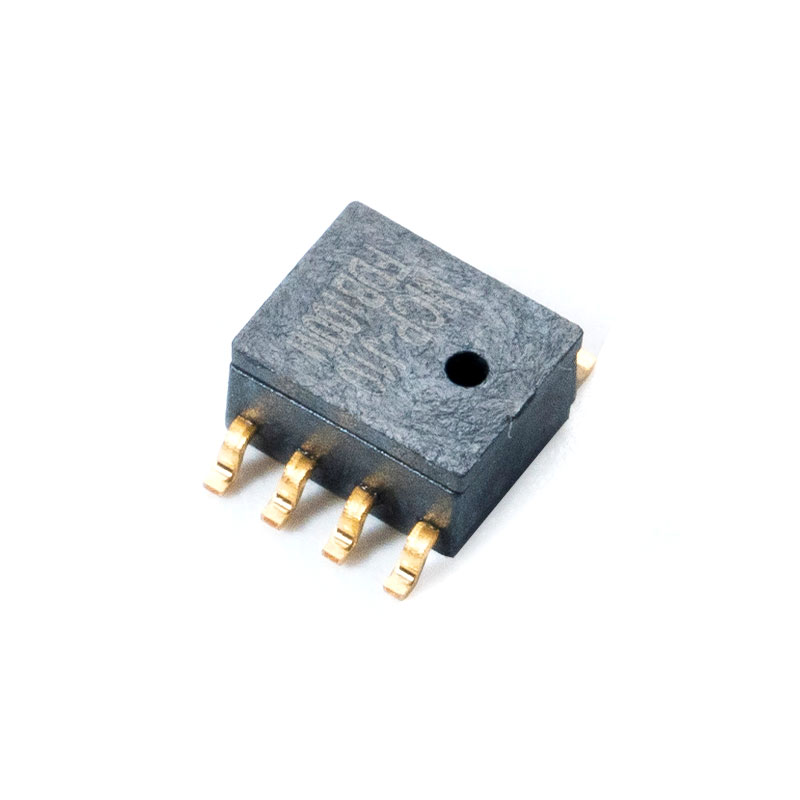

Selecting the right pressure sensing solution for medical ventilators requires understanding both technical specifications and clinical requirements. This guide examines the critical factors for implementing MCP Pressure Sensor For Medical ventilators to ensure reliability, accuracy, and regulatory compliance in life-support applications.

The Vital Role of Pressure Sensing in Modern Ventilator Systems

Pressure monitoring serves as the fundamental feedback mechanism in mechanical ventilation, ensuring precise delivery of therapeutic air mixtures while preventing patient lung injury. Modern ventilators employ multiple MCP pressure sensor for ventilator applications at strategic points to monitor airway pressure, calculate tidal volume, and detect patient breathing efforts. The consequence of sensor failure in this context extends beyond device malfunction to potential patient harm, making reliability the paramount concern in sensor selection and system design. These sensors must maintain accuracy while exposed to challenging conditions including humidified gases, temperature variations, and continuous pressure cycling.

Understanding Ventilator Pressure Sensing Points

The placement of pressure sensors within a ventilator system dictates their specific performance requirements and operational challenges. Each monitoring location serves a distinct clinical purpose with unique engineering considerations.

Airway Pressure Monitoring

Proximal airway pressure sensors measure pressure delivered directly to the patient's lungs, providing primary feedback for ventilation control and safety limits. These sensors must handle challenging environmental conditions while maintaining accuracy.

- Measures inspiratory and expiratory pressures at patient connection point

- Critical for pressure-controlled ventilation modes and safety monitoring

- Requires robust compensation for temperature and humidity variations

Flow Sensing and Volume Calculation

Differential pressure sensors enable precise measurement of gas flow, which integrates to determine tidal volume. This application demands exceptional stability and minimal hysteresis.

- Differential pressure measurement across fixed flow resistance

- Enables calculation of inspired and expired tidal volumes

- Requires high resolution at low pressure differentials

Oxygen Source Pressure Monitoring

Upstream pressure monitoring ensures adequate oxygen supply and detects line pressure issues before patient impact. These sensors operate at higher pressures than airway sensors.

- Monitors medical gas supply pressure (typically 345-620 kPa)

- Provides early warning of supply system issues

- Higher pressure range capability required

Key Specifications for Medical-Grade MCP Pressure Sensors

Beyond standard industrial requirements, medical ventilator applications demand exceptional performance across specific parameters that directly impact patient care.

Accuracy and Long-Term Stability Requirements

Ventilator applications require total error band specifications that include combined effects of nonlinearity, hysteresis, and thermal errors. Typical medical grade MCP pressure sensor specifications should guarantee better than 1% total error band across the operating range. Long-term stability becomes critical for maintaining calibration throughout the device service life without compromising patient safety.

Fast Response Time for Patient Synchronization

Modern ventilation modes require rapid sensor response to detect patient-initiated breaths. A properly specified MCP Pressure Sensor For Medical ventilators must achieve step response times under 2 milliseconds to accurately capture inspiratory effort, enabling timely ventilator response that improves patient-ventilator synchrony.

- Rapid detection of patient inspiratory effort

- Enables responsive pressure support delivery

- Minimizes work of breathing during assisted ventilation

Biocompatibility and Material Safety Standards

For sensors exposed to breathing gases, compliance with ISO 18562 for biocompatibility evaluation of breathing gas pathways is mandatory. This standard addresses risks from particle release and leachable substances that could contaminate the breathing circuit.

Ensuring Reliability and Safety in Critical Care

Ventilator sensors must demonstrate fault-tolerant design and predictable failure modes to meet the safety standards expected in critical care environments. The principles defining a high reliability MCP pressure sensor for patient monitoring apply with greater stringency in life-support applications.

Design for Fault Tolerance and Fail-Safe Operation

Medical-grade MCP sensors should incorporate design features that ensure predictable failure modes. These include redundant sensing elements, built-in self-test capabilities, and output behaviors that clearly indicate fault conditions to the ventilator monitoring system.

EMI/EMC Performance in Hospital Environments

Hospital environments contain numerous potential sources of electromagnetic interference. A properly designed high reliability MCP pressure sensor for patient monitoring must demonstrate immunity to RF fields and electrostatic discharge per IEC 60601-1-2, ensuring uninterrupted operation despite environmental interference.

Testing Under Simulated Clinical Conditions

Beyond standard environmental testing, ventilator-bound sensors should undergo validation under conditions simulating clinical use, including exposure to disinfectants and accelerated life cycling representing years of continuous operation.

Compliance and Manufacturing Requirements

The regulatory framework governing medical devices imposes specific requirements on component selection and supplier management extending beyond technical specifications.

Medical Quality Standards and Documentation

When evaluating an ISO 13485 MCP pressure sensor manufacturer, verify their quality management system includes comprehensive design controls, risk management, and thorough documentation practices. The manufacturer should provide device history records and support regulatory submissions with detailed technical documentation.

Supply Chain Traceability and Consistency

Medical device manufacturers require complete traceability of critical components, necessitating sensors supplied with unique lot identifiers and certificates of conformity. Consistent performance across production lots prevents recalibration needs with each component shipment.

Disposable vs. Reusable Design Considerations

The growing emphasis on infection control has driven increased adoption of single-use medical devices, creating distinct sensor requirements.

| Consideration | Reusable Sensors | Disposable Sensors |

| Sterilization Compatibility | Must withstand repeated sterilization cycles | Single-use eliminates sterilization requirement |

| Cost Structure | Higher initial cost with long service life | Lower per-unit cost with no reprocessing |

| Performance Requirements | Proven long-term stability and drift characteristics | Calibration stability for single procedure |

| Regulatory Pathway | Component of durable medical equipment | Part of single-use device submission |

The development of disposable medical pressure sensor MCP technology represents significant engineering innovation in cost-optimized manufacturing while maintaining clinical accuracy. These sensors eliminate cross-contamination risks while simplifying ventilator design through compact, single-patient-use packages.

Ventilator Sensor Selection Checklist

Use this comprehensive checklist to evaluate potential MCP pressure sensor for ventilator applications during design and sourcing.

- Does total error band specification include all combined error sources?

- Has the sensor been validated for humidified gases and condensation?

- Can the manufacturer provide EMI/EMC test results per IEC 60601-1-2?

- Are material declarations and biocompatibility test reports available?

- Does the manufacturer maintain ISO 13485 certification with design controls?

- What failure mode analysis and fault detection capabilities are implemented?

- Can the supplier ensure lot-to-lot consistency with full traceability?

FAQ

What is the typical lifespan requirement for MCP sensors in continuous-use ventilators?

Ventilators used in critical care typically require sensor lifespans exceeding 5-10 years of continuous operation, representing millions of breathing cycles. Medical-grade MCP Pressure Sensor For Medical applications should demonstrate long-term drift specifications maintaining accuracy throughout this service life. Manufacturers validate this through accelerated life testing simulating years of operation under realistic environmental and pressure cycling conditions.

How does condensation affect pressure sensor accuracy in ventilator circuits?

Condensation presents significant challenges as water droplets can block pressure ports or create measurement artifacts. Medical MCP pressure sensor for ventilator applications incorporate specialized hydrophobic filters or membrane systems that allow air pressure transmission while blocking liquid water. Signal processing should include algorithms to detect and compensate for minor temperature effects caused by water evaporation at the pressure port.

Can the same MCP sensor be used for both invasive and non-invasive ventilation?

While technically possible, optimal performance typically requires different sensor specifications. Invasive ventilation demands higher accuracy at lower pressures and faster response times for patient-triggered modes. Non-invasive ventilation often involves dealing with larger leaks and more variable pressure conditions. Many manufacturers select different medical grade MCP pressure sensor specifications for these distinct clinical applications to optimize performance and cost-effectiveness.

What redundancy approaches are recommended for critical ventilator pressure monitoring?

For mission-critical pressure measurements like airway pressure, redundant sensing implementations are common. Approaches include dual independent sensors with continuous cross-comparison, primary sensors with lower-accuracy backups for fault detection, and differential configurations providing inherent redundancy. The specific approach depends on the ventilator safety classification and risk analysis, with more robust redundancy required for life-supporting functions.

How are MCP sensors validated for use with oxygen-rich environments?

Sensors for medical oxygen undergo rigorous material compatibility testing and cleanroom assembly processes. Validation includes material testing per ISO 15001 for oxygen compatibility, particle counting of exhaust gases to ensure cleanliness, and specialized packaging procedures to prevent hydrocarbon contamination. These measures ensure the MCP Pressure Sensor For Medical oxygen applications does not introduce ignition risks or contaminants into the breathing gas stream.

Recommended Articles

English

English Français

Français 中文简体

中文简体