MCP Absolute/Gauge/Differential Pressure Sensor Manufacturers

-

Understanding Medium Pressure Sensors A Medium Pressure Sensor is a precision sensing device designed to measure pressure levels that fall between low-pressure and high-pressure ranges. These sensors are widely used in systems where stable, accurate pressure monitoring is essential but extreme pressure resistance is no...

VIEW MORE

-

Pressure sensing is a fundamental capability that bridges the physical and digital worlds, enabling everything from weather forecasting to life-saving medical interventions. Among the various types, the absolute pressure sensor holds a unique and critical position. But what exactly sets it apart? Unlike sensors that me...

VIEW MORE

-

In the rapidly evolving landscape of modern engineering and electronic design, the demand for precise, reliable, and compact sensing solutions is at an all-time high. Among the myriad of technologies available, the MCP Pressure Sensor has emerged as a critical component for a wide array of applications, ranging from in...

VIEW MORE

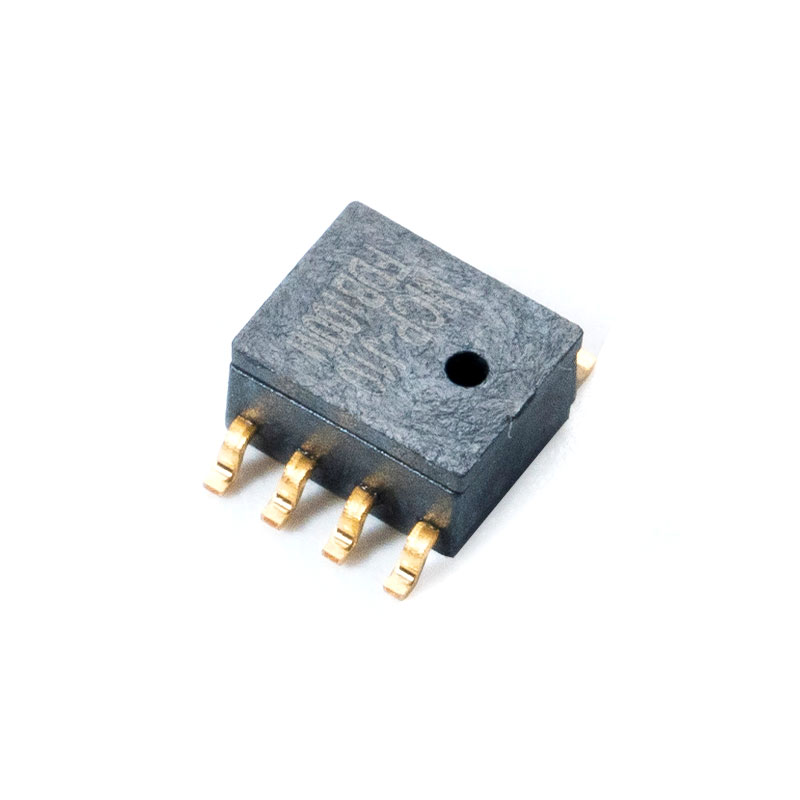

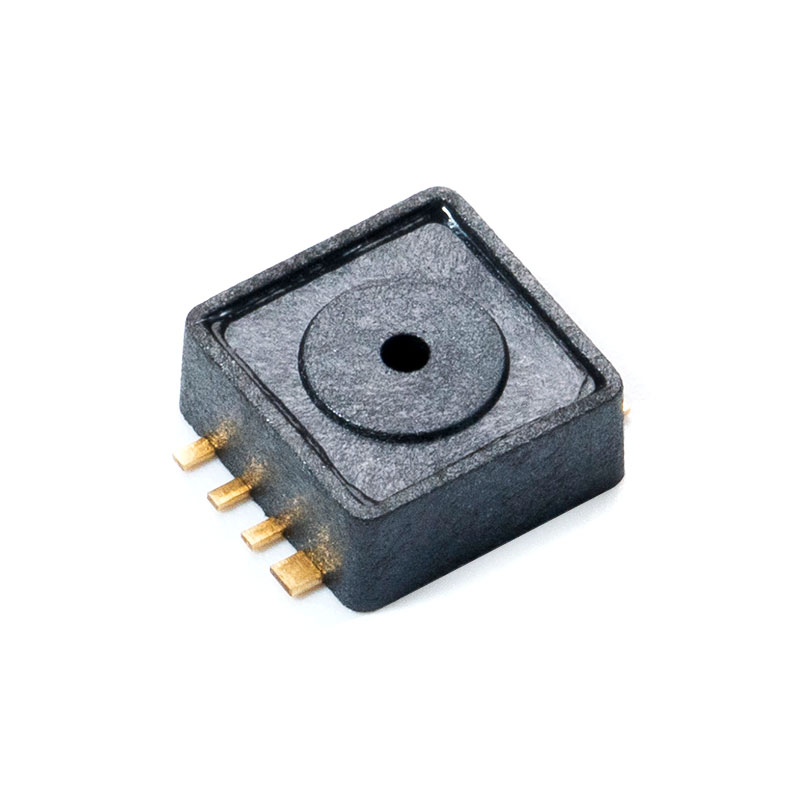

Understanding MCP Absolute, Gauge, and Differential Pressure Sensors: Key Differences and Applications

Wuxi Mems Tech Co., Ltd., founded in 2011 and located in Wuxi National Hi-tech District—China's hub for IoT innovation—specializes in the research, development, production, and sales of MEMS pressure sensors. With professional expertise, advanced manufacturing systems, and strict quality control, the company provides high-performance and cost-effective pressure sensing solutions for industries such as medical, automotive, and consumer electronics.

What Are MCP Pressure Sensors?

MCP pressure sensors are microelectromechanical devices designed to measure pressure in absolute, gauge, or differential modes. They are a critical component in modern automation, control, and monitoring systems. These sensors convert pressure changes into electrical signals that can be easily processed by control units or monitoring systems.

Types of MCP Pressure Sensors

- Absolute Pressure Sensors (MCP Absolute): Measure pressure relative to a perfect vacuum. They are often used in environments where atmospheric pressure variation must be eliminated, such as aerospace, weather monitoring, and vacuum systems.

- Gauge Pressure Sensors (MCP Gauge): Measure pressure relative to ambient atmospheric pressure. These are common in automotive tire pressure monitoring, HVAC systems, and fluid control applications.

- Differential Pressure Sensors (MCP Differential): Measure the difference between two pressure points. They are widely used in filtration systems, air flow measurement, and industrial process control.

Key Differences Between MCP Absolute, Gauge, and Differential Sensors

| Sensor Type | Reference Pressure | Typical Applications | Advantages |

|---|---|---|---|

| Absolute | Vacuum (0 Pa) | Altitude measurement, aerospace, vacuum packaging | Unaffected by atmospheric pressure changes |

| Gauge | Ambient atmosphere | Automotive tire pressure, water pumps, industrial tanks | Ideal for comparing system pressure to the environment |

| Differential | Two separate pressure points | Air flow, filters, HVAC systems, process control | High precision in flow and level measurement |

Applications of MCP Pressure Sensors

1. Medical Equipment

In medical systems, MCP sensors are used for precise pressure control in ventilators, infusion pumps, and blood pressure monitoring. Their compact size and accuracy make them ideal for medical-grade devices.

2. Automotive Industry

MCP sensors play a vital role in modern vehicles—monitoring tire pressure, engine air intake, and oil systems. The high stability and thermal resistance of MEMS-based sensors ensure reliable performance under extreme conditions.

3. Consumer Electronics

In smartphones, wearables, and smart home devices, MCP sensors enable barometric altimeters, weather detection, and air pressure adjustments. Their low power consumption supports energy-efficient applications.

4. Industrial Automation

In automation systems, MCP differential pressure sensors provide feedback for flow control, HVAC systems, and process monitoring. Their precision supports the optimization of energy usage and system safety.

Why Choose Wuxi Mems Tech Co., Ltd.

- Advanced MEMS Technology: Developed through years of R&D, ensuring consistent accuracy and sensitivity.

- Wide Product Range: From MCP absolute to differential pressure sensors for diverse applications.

- High Reliability: Each sensor undergoes rigorous testing for stability and durability in various environments.

- Cost-Effective Solutions: Competitive pricing without compromising performance or quality.

Conclusion

MCP Absolute, Gauge, and Differential Pressure Sensors each serve specific roles across industries requiring accurate and stable pressure measurement. As a professional manufacturer, Wuxi Mems Tech Co., Ltd. continues to deliver innovative MEMS-based pressure sensors that meet global standards in performance, precision, and reliability—empowering industries from medical to automotive to embrace smarter sensing technologies.

Frequently Asked Questions (FAQ)

1. What is the main difference between an absolute and a gauge pressure sensor?

An absolute pressure sensor measures pressure relative to a perfect vacuum, while a gauge pressure sensor measures pressure relative to the surrounding atmospheric pressure. Absolute sensors are ideal for altitude and vacuum applications, while gauge sensors are used in systems like HVAC and automotive monitoring.

2. Where are MCP differential pressure sensors most commonly used?

MCP differential pressure sensors are mainly used in industrial automation, HVAC systems, filter monitoring, and air flow measurement. They are essential for detecting small pressure variations between two environments or pipelines.

3. How does MEMS technology improve MCP pressure sensor performance?

MEMS (Micro-Electro-Mechanical Systems) technology allows sensors to be smaller, more precise, and more energy-efficient. It enhances long-term stability, reduces drift, and ensures reliable measurement under varying environmental conditions.

4. Can MCP pressure sensors be customized for specific industrial applications?

Yes, Wuxi Mems Tech Co., Ltd. offers customization options to meet specific measurement ranges, pressure interfaces, and electrical outputs, allowing integration into specialized systems across different industries.

5. What factors should be considered when choosing an MCP pressure sensor?

Key factors include pressure range, medium compatibility, temperature tolerance, accuracy requirements, and the type of reference pressure (absolute, gauge, or differential). Selecting the right model ensures accurate and reliable performance for your application.

English

English Français

Français 中文简体

中文简体