Micro/Low pressure/Medium Pressure Sensor Manufacturers

-

Understanding Medium Pressure Sensors A Medium Pressure Sensor is a precision sensing device designed to measure pressure levels that fall between low-pressure and high-pressure ranges. These sensors are widely used in systems where stable, accurate pressure monitoring is essential but extreme pressure resistance is no...

VIEW MORE

-

Pressure sensing is a fundamental capability that bridges the physical and digital worlds, enabling everything from weather forecasting to life-saving medical interventions. Among the various types, the absolute pressure sensor holds a unique and critical position. But what exactly sets it apart? Unlike sensors that me...

VIEW MORE

-

In the rapidly evolving landscape of modern engineering and electronic design, the demand for precise, reliable, and compact sensing solutions is at an all-time high. Among the myriad of technologies available, the MCP Pressure Sensor has emerged as a critical component for a wide array of applications, ranging from in...

VIEW MORE

How Are MEMS Pressure Sensors Shaping Modern Industry Applications and What Makes MCP Sensors Stand Out?

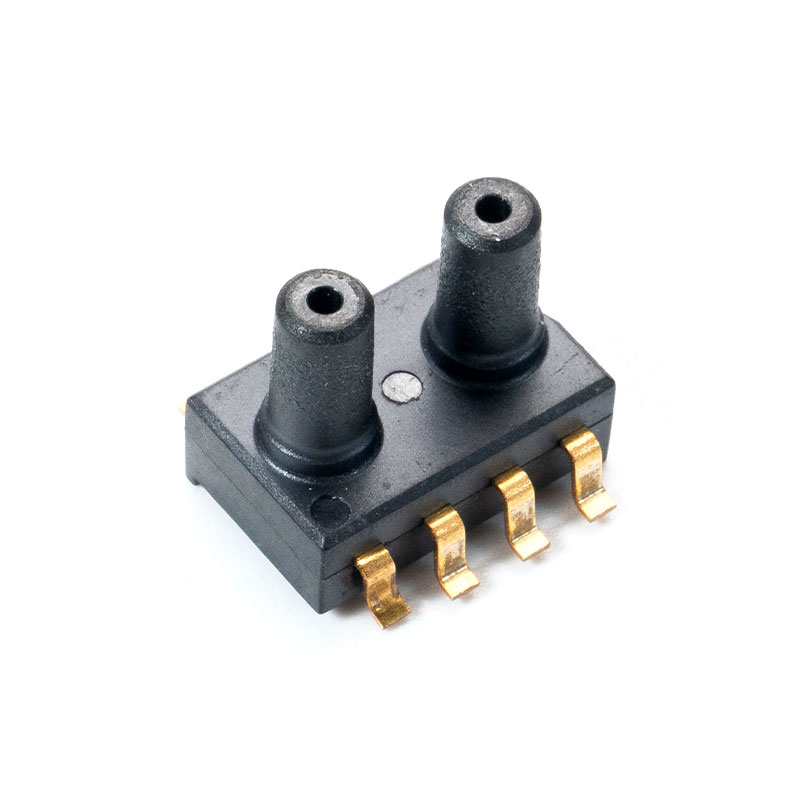

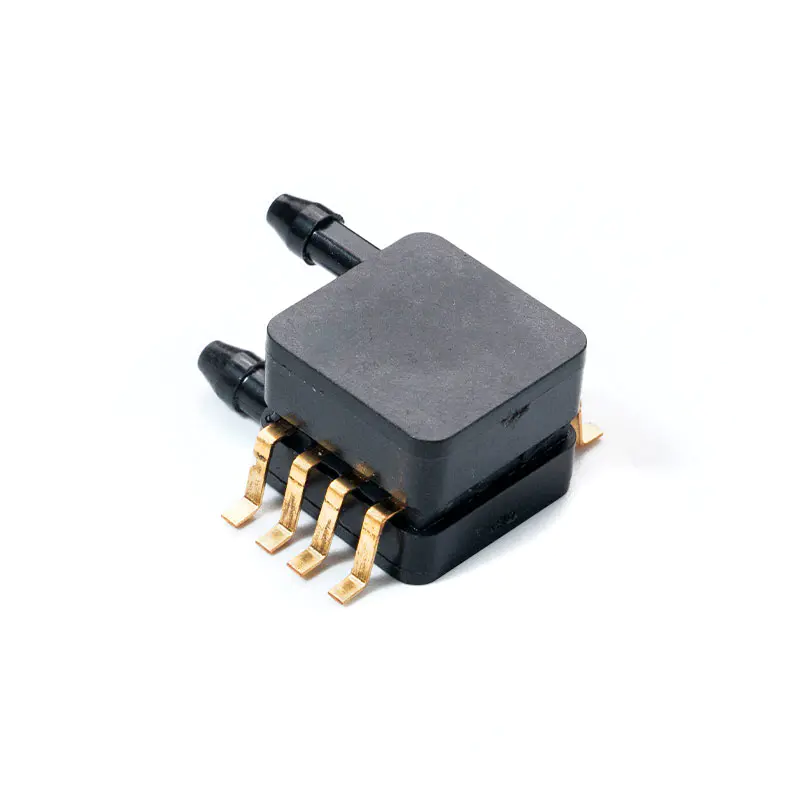

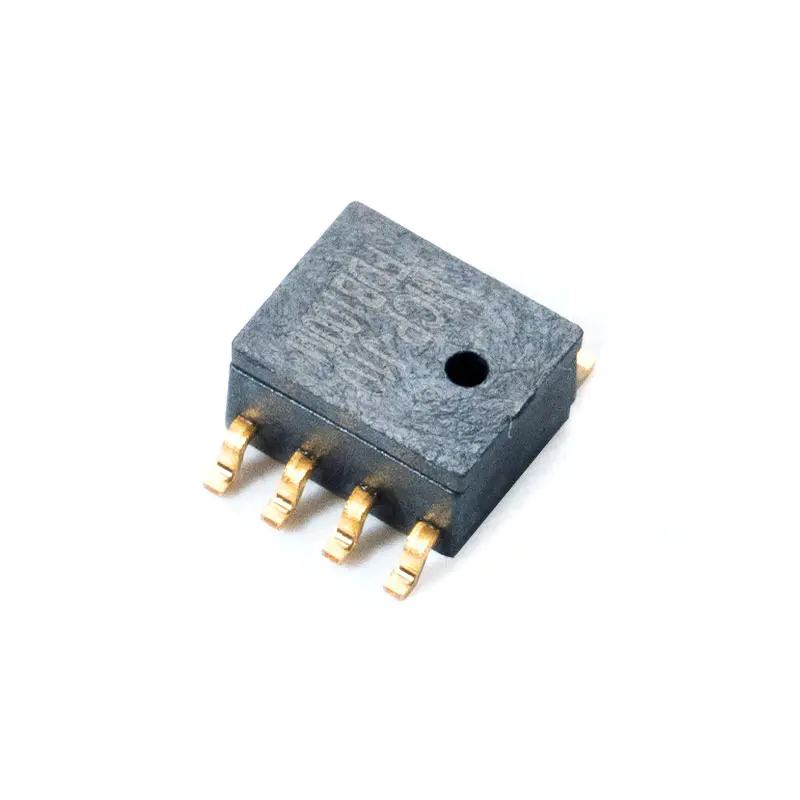

In the rapidly evolving landscape of electronic sensing technologies, MEMS (Micro-Electro-Mechanical Systems) pressure sensors have emerged as pivotal components across medical, automotive, and consumer electronics sectors. Among these, MCP micro pressure sensor, MCP low pressure sensor, and MCP medium pressure sensor have gained significant traction for their precision, reliability, and adaptability. Understanding the technological nuances, manufacturing standards, and application breadth of these sensors is essential for professionals seeking high-performance and cost-effective sensing solutions.

Technological Overview of MEMS Pressure Sensors

MEMS pressure sensors operate by converting mechanical deflection into electrical signals. Their miniature structure enables integration into compact systems without sacrificing sensitivity or stability. Depending on their target application, sensors are categorized based on pressure range:

- MCP Micro Pressure Sensor: Designed for detecting minute pressure variations, often in medical devices, environmental monitoring, or precision instrumentation. These sensors must offer high sensitivity and low noise to ensure accurate measurements at micro-scale pressure levels.

- MCP Low Pressure Sensor: Suited for applications requiring the monitoring of small but slightly larger pressure variations than micro-level sensors. Examples include HVAC systems, pneumatic devices, and low-pressure fluid management in industrial processes.

- MCP Medium Pressure Sensor: Targets applications involving moderate pressure ranges, such as automotive fuel systems, industrial equipment, and consumer appliances. These sensors combine robustness with accuracy to operate reliably under variable conditions.

The core advantage of MEMS technology lies in its ability to deliver high-resolution measurements within compact footprints, enabling integration into systems where traditional sensors would be impractical.

Manufacturing Excellence and Quality Assurance

High-performance MEMS pressure sensors rely not only on innovative design but also on meticulous manufacturing processes. Wuxi Mems Tech Co., Ltd., specializing in MEMS pressure sensor R&D, production, and sales, exemplifies excellence in this domain. Their manufacturing pipeline incorporates the following key practices:

Quality Management: The production process strictly adheres to ISO quality standards. Every sensor undergoes zero/full-scale calibration to verify its operational accuracy. Temperature drift testing ensures reliability across environmental fluctuations, while long-term stability evaluation confirms consistent performance over time. This rigorous approach guarantees batch-to-batch consistency, which is critical for industrial and medical applications.

Manufacturing Capability: Wuxi Mems Tech operates a standardized production line encompassing packaging, soldering, temperature compensation, performance calibration, and full-process quality control. From prototyping to mass production, each stage integrates automated and manual inspections to minimize defects and maximize yield. Such comprehensive in-house capabilities allow for faster development cycles and tailored solutions for diverse industrial needs.

Application Spectrum

MEMS pressure sensors, including MCP series variants, have wide-ranging applications due to their sensitivity, compact size, and robustness:

- Medical Devices: Micro and low-pressure sensors are critical in ventilators, infusion pumps, and non-invasive blood pressure monitors. Accurate measurement of small pressure variations directly impacts patient safety and treatment efficacy.

- Automotive Industry: Medium and low-pressure sensors monitor tire pressure, fuel injection systems, and exhaust gas recirculation. Their precision helps improve vehicle efficiency, emissions control, and safety.

- Consumer Electronics: Sensors enable barometric altimeters in smartphones, wearable devices, and smart home appliances. Micro pressure detection facilitates enhanced user experiences and device reliability.

In all applications, sensor performance must balance sensitivity, stability, and durability. The MCP series achieves this by combining advanced MEMS design with rigorous manufacturing standards.

Advantages of MCP Pressure Sensors

The MCP micro, low, and medium pressure sensors exhibit several intrinsic advantages:

- High Accuracy and Stability: Zero/full-scale calibration and temperature compensation ensure readings remain precise over time and environmental conditions.

- Compact Size: MEMS fabrication techniques allow integration into devices with limited space without sacrificing performance.

- Cost-Effectiveness: Efficient manufacturing and in-house capabilities reduce production costs, making high-performance sensors accessible for large-scale deployment.

- Versatility: The availability of micro, low, and medium pressure ranges allows application across diverse industries, simplifying component sourcing and standardization.

Future Trends and Industry Insights

As industrial automation, smart devices, and medical instrumentation evolve, demand for reliable, compact, and cost-effective pressure sensors is expected to grow. Key trends include:

- Miniaturization: Devices continue to shrink, requiring sensors with smaller footprints without compromising accuracy. MCP micro pressure sensors are particularly relevant in this context.

- IoT Integration: Sensors increasingly interface with wireless and cloud-based monitoring systems, necessitating high stability and low power consumption.

- Advanced Materials and Packaging: Emerging packaging techniques and materials enhance sensor durability, enabling performance under extreme temperatures and corrosive environments.

- Data-Driven Optimization: Continuous calibration and self-monitoring algorithms improve long-term reliability, particularly in automotive and medical applications.

Wuxi Mems Tech Co., Ltd. is well-positioned to address these trends thanks to its R&D capabilities, rigorous quality control, and flexible production lines.

Selection Criteria for MCP Sensors

When selecting an MCP Micro, Low, or Medium Pressure Sensor, key considerations include:

- Pressure Range: Ensure the sensor matches the target operational pressure without saturation or under-measurement.

- Environmental Conditions: Evaluate temperature fluctuations, vibration, and exposure to chemicals that could affect performance.

- Integration Requirements: Assess footprint, electrical interfaces, and compatibility with existing systems.

- Accuracy and Stability Needs: Determine whether long-term stability and minimal drift are critical for the application.

Choosing the correct sensor range and specifications directly affects device reliability and overall system performance.

Summary

MEMS pressure sensors are integral to modern technological applications. By combining rigorous manufacturing, ISO-aligned quality management, and adaptable design, MCP sensors enable engineers and device manufacturers to achieve precise, reliable, and cost-effective sensing solutions.

English

English Français

Français 中文简体

中文简体