Medium pressure sensor Manufacturers

Medium pressure sensors are industrial sensors used to measure pressures in the range of 100~1500kPa and are widely used in hydraulic systems, pneumatic control, industrial automation, energy equipment, process control, etc. The core function is to convert gas or liquid pressure signals in the medium pressure range into standard electrical signals (such as 4~20mA, 0~10V or digital signals), providing accurate data support for system monitoring, regulation and safety protection.

-

Understanding Medium Pressure Sensors A Medium Pressure Sensor is a precision sensing device designed to measure pressure levels that fall between low-pressure and high-pressure ranges. These sensors are widely used in systems where stable, accurate pressure monitoring is essential but extreme pressure resistance is no...

VIEW MORE

-

Pressure sensing is a fundamental capability that bridges the physical and digital worlds, enabling everything from weather forecasting to life-saving medical interventions. Among the various types, the absolute pressure sensor holds a unique and critical position. But what exactly sets it apart? Unlike sensors that me...

VIEW MORE

-

In the rapidly evolving landscape of modern engineering and electronic design, the demand for precise, reliable, and compact sensing solutions is at an all-time high. Among the myriad of technologies available, the MCP Pressure Sensor has emerged as a critical component for a wide array of applications, ranging from in...

VIEW MORE

What Are the Key Advantages of Medium Pressure Sensors in Modern Technology?

Medium pressure sensors have become indispensable in modern industry and consumer electronics, providing precise measurement of fluid and gas pressures in systems ranging from automotive engines to medical devices. Their role is critical for monitoring, control, and safety, ensuring that equipment operates within designated pressure ranges. Unlike low-pressure or micro-pressure sensors, medium pressure sensors are designed to reliably measure pressures typically from 0.1 MPa up to several tens of MPa, offering a balance between sensitivity and durability.

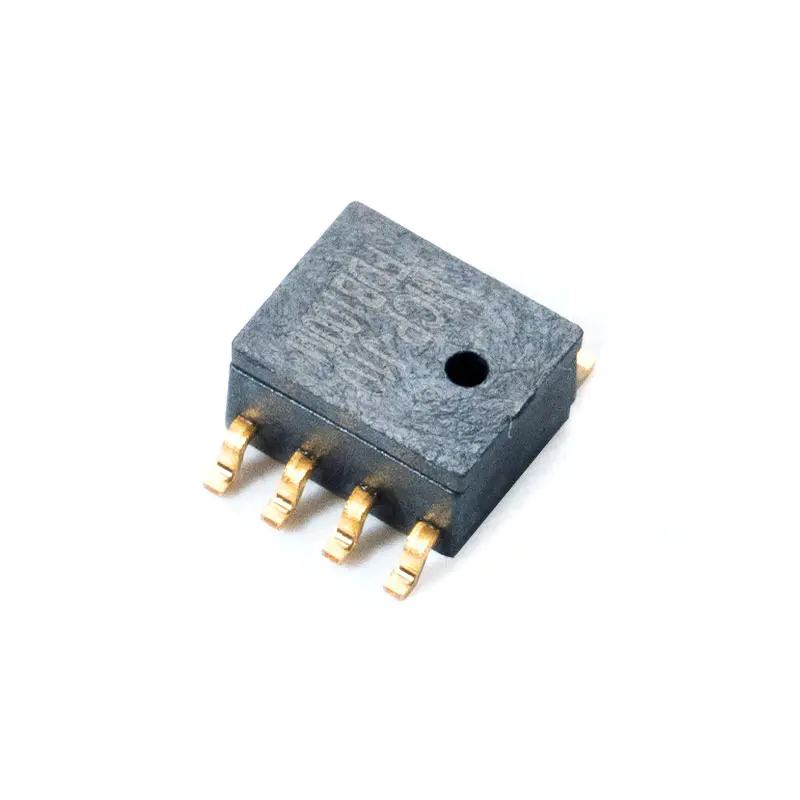

At the core of these sensors, microelectromechanical systems (MEMS) technology enables miniaturized, high-precision components capable of converting pressure variations into electrical signals with minimal error. Wuxi Mems Tech Co., Ltd., specializing in the R&D, production, and sales of MEMS pressure sensors, exemplifies industry-leading practices by providing solutions that combine accuracy, stability, and cost-effectiveness. Their products are widely adopted in sectors including medical, automotive, and consumer electronics, reflecting the versatile nature of medium pressure sensing technology.

Quality Management in Medium Pressure Sensor Production

The foundation of reliable medium pressure sensors is rigorous quality management. Every sensor must undergo comprehensive testing to guarantee performance under varying operational conditions. Wuxi Mems Tech Co., Ltd. enforces ISO-compliant manufacturing standards, conducting zero/full-scale calibration, temperature drift evaluation, and long-term stability testing. MCP-H10 sensors achieve ±1.5% VFSS accuracy, while the MCP/V series maintains ±1.5% to ±2.5% across its models. Such stringent control ensures consistent and accurate output, which is critical for applications like automotive fuel injection systems or medical ventilators, where precise pressure readings directly affect safety and functionality.

Medium pressure sensors are also tested for repeatability and hysteresis to ensure that cyclic pressures do not compromise measurement accuracy. Furthermore, temperature compensation techniques are integrated to minimize error due to environmental fluctuations, making these sensors suitable for both industrial plants with high-temperature variations and portable medical devices exposed to patient body heat.

Manufacturing Capabilities and Process Control

The ability to produce reliable medium pressure sensors at scale depends on advanced manufacturing processes. Wuxi Mems Tech Co., Ltd. operates a 2,000 m² standardized facility, capable of full-process in-house production. From prototyping to mass production, all stages—including packaging, soldering, temperature compensation, and performance calibration—are carefully monitored.

Strict quality control protocols ensure each sensor meets predefined specifications. RoHS compliance guarantees environmentally safe materials, while internal calibration processes maintain accuracy across production batches. Customization is a key differentiator; the company can adapt packaging, pressure range, and output format according to client needs, enabling seamless integration into diverse applications, from industrial automation to consumer electronics.

Technological Innovation and Stability

In medium pressure sensor design, stability is paramount. Material selection, sensor diaphragm design, and packaging architecture are optimized to reduce mechanical stress and thermal effects. By prioritizing stability, Wuxi Mems Tech Co., Ltd. ensures that sensors deliver accurate readings over long service lifetimes, even under high-cycle or high-pressure conditions.

Application-oriented customization further enhances usability. Recognizing that each system has unique mechanical and electrical interfaces, the company provides tailored solutions, including hardware adaptations and firmware calibration, to match specific application requirements. For instance, automotive customers may require sensors with high-frequency response and resistance to vibration, while medical devices demand ultra-clean packaging and low power consumption.

Medium pressure sensors also benefit from technology-driven iterative design. Real-world testing and data analytics guide each development cycle, ensuring that improvements are based on practical evidence rather than theoretical assumptions. This approach ensures that sensors not only meet technical specifications but also address operational challenges faced by end users.

Key Applications of Medium Pressure Sensors

1. Automotive Industry

In vehicles, medium pressure sensors monitor fuel rails, turbocharger boost pressure, and hydraulic braking systems. Accurate pressure data optimizes engine performance, reduces emissions, and enhances safety features like anti-lock braking systems (ABS). The ability to withstand high temperatures and vibrations is critical, emphasizing the need for robust design and precise calibration.

2. Medical Devices

Medium pressure sensors are widely used in ventilators, blood pressure monitoring equipment, and infusion pumps. Accuracy and stability are essential to patient safety. MEMS-based designs offer compact form factors, low power consumption, and rapid response, making them ideal for critical healthcare applications.

3. Industrial Automation

In industrial processes, medium pressure sensors facilitate pneumatic and hydraulic control, ensuring machinery operates within safe pressure ranges. These sensors contribute to energy efficiency, prevent equipment damage, and maintain process consistency in sectors like chemical manufacturing, food processing, and robotics.

4. Consumer Electronics

Emerging applications in consumer devices, such as smart home systems and portable air compressors, leverage medium pressure sensors to monitor environmental conditions and fluid systems. Compact design, reliability, and low-cost production are key for widespread adoption in this market segment.

Advantages of MEMS Medium Pressure Sensors

MEMS-based medium pressure sensors offer multiple advantages over traditional sensing methods:

- High Precision and Linearity: Accurate measurement across a wide pressure range.

- Miniaturization: Compact design enables integration into small-scale devices.

- Low Power Consumption: Essential for battery-powered medical and consumer electronics.

- Fast Response Time: Rapid detection of pressure changes improves system responsiveness.

- Durability and Stability: Designed to withstand mechanical stress, temperature variations, and chemical exposure.

Future Trends in Medium Pressure Sensor Technology

The medium pressure sensor industry is evolving rapidly with several notable trends:

- IoT Integration: Sensors increasingly communicate wirelessly with control systems, enabling real-time monitoring and predictive maintenance.

- Advanced Materials: Development of novel diaphragm materials improves sensitivity and long-term stability.

- Multi-Parameter Sensing: Sensors combining pressure, temperature, and flow measurement reduce component count and simplify system integration.

- Miniaturization and Wearables: Smaller sensors support compact consumer electronics and portable medical devices.

- AI-Driven Calibration: Machine learning algorithms optimize calibration and compensate for environmental drift, enhancing accuracy in dynamic conditions.

These trends indicate that medium pressure sensors will continue to expand their reach across traditional and emerging markets, offering smarter, more reliable, and cost-effective solutions.

Conclusion

In summary, medium pressure sensors are critical components in a wide array of applications, from automotive and medical devices to industrial automation and consumer electronics. As demand for precise and compact sensing solutions grows, medium pressure sensors will continue to evolve, integrating new materials, intelligent calibration, and multi-functional capabilities. Understanding their role, design considerations, and manufacturing processes is essential for engineers, designers, and decision-makers aiming to implement reliable pressure measurement solutions in complex systems.

English

English Français

Français 中文简体

中文简体