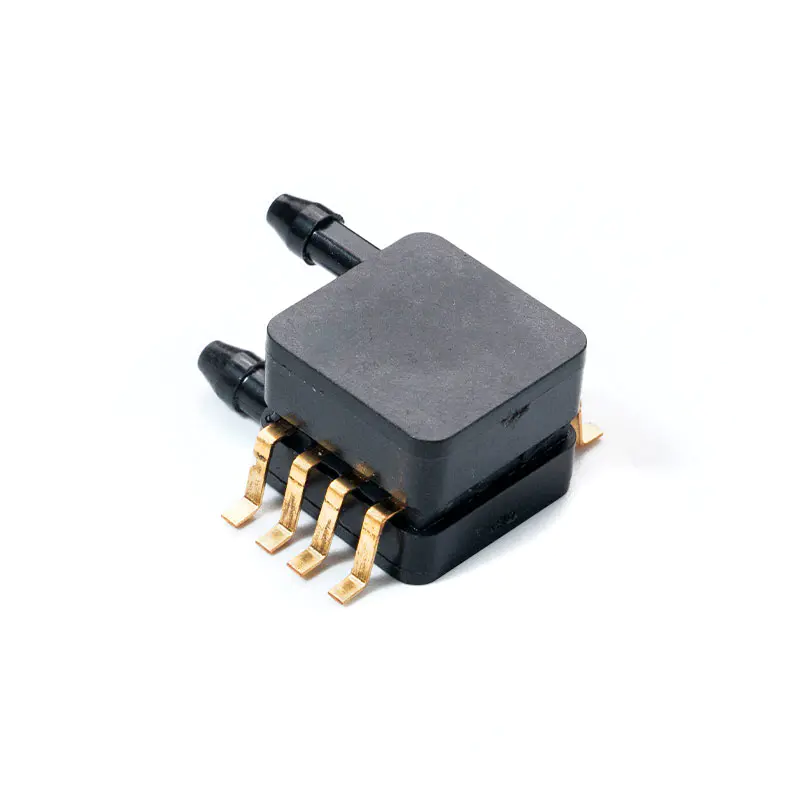

Low pressure sensor Manufacturers

Low-pressure sensors are precision devices used to measure gas or liquid pressure in the range of 1~100kPa, with the characteristics of high sensitivity, low error and stability. Application scenarios include medical ventilators, environmental air pressure monitoring, industrial process control (such as ventilation systems, clean room pressure regulation) and laboratory fluid analysis. Using MEMS (micro-electromechanical systems), strain gauges or capacitive technology, it can accurately capture tiny pressure changes, and some models are also compatible with corrosive media or extreme temperature environments.

-

Understanding Medium Pressure Sensors A Medium Pressure Sensor is a precision sensing device designed to measure pressure levels that fall between low-pressure and high-pressure ranges. These sensors are widely used in systems where stable, accurate pressure monitoring is essential but extreme pressure resistance is no...

VIEW MORE

-

Pressure sensing is a fundamental capability that bridges the physical and digital worlds, enabling everything from weather forecasting to life-saving medical interventions. Among the various types, the absolute pressure sensor holds a unique and critical position. But what exactly sets it apart? Unlike sensors that me...

VIEW MORE

-

In the rapidly evolving landscape of modern engineering and electronic design, the demand for precise, reliable, and compact sensing solutions is at an all-time high. Among the myriad of technologies available, the MCP Pressure Sensor has emerged as a critical component for a wide array of applications, ranging from in...

VIEW MORE

How Can Low Pressure Sensors Transform Precision Measurement Across Industries?

In modern technology-driven industries, accurate pressure measurement has become a critical requirement. Low pressure sensors, designed to detect minimal variations in pressure, play an indispensable role in sectors ranging from medical devices to automotive systems and consumer electronics. These sensors provide precise, reliable, and real-time data that enable optimal system performance, safety, and efficiency.

Overview of Low Pressure Sensors

A low pressure sensor is a device specifically engineered to measure small pressure differentials, typically in the range of a few pascals to several kilopascals. Unlike high-pressure sensors, which monitor robust industrial or hydraulic systems, low pressure sensors are optimized for sensitivity and stability under delicate or fluctuating conditions. This makes them ideal for environments where minor pressure changes can have significant effects on system behavior or product functionality.

The design of a low pressure sensor typically integrates a sensitive diaphragm, a strain gauge, or MEMS (Micro-Electro-Mechanical Systems) technology to convert physical pressure into an electrical signal. MEMS-based low pressure sensors, in particular, have become increasingly prevalent due to their compact size, high precision, low power consumption, and mass production feasibility.

Core Working Principles

Low pressure sensors operate on fundamental principles of mechanical deformation and electrical signal conversion. When external pressure acts on the sensor diaphragm, it causes a measurable deflection. This mechanical deformation is then translated into a corresponding electrical output through piezoresistive, capacitive, or piezoelectric transduction methods.

- Piezoresistive sensors rely on changes in electrical resistance caused by strain in the sensing element.

- Capacitive sensors detect variations in capacitance resulting from diaphragm displacement.

- Piezoelectric sensors generate an electric charge directly proportional to applied pressure.

By combining precision materials and advanced MEMS fabrication techniques, modern low pressure sensors achieve high linearity, minimal hysteresis, and excellent long-term stability, which are essential for critical applications such as medical respiratory devices or automotive engine management systems.

Technological Advancements and Trends

The development of low pressure sensors is closely linked to advancements in MEMS technology, miniaturization, and intelligent sensing systems. Wuxi Mems Tech Co., Ltd. is a company specializing in the research, development, production, and sales of MEMS pressure sensors, fully demonstrating how technology-driven design can improve performance across various application areas.

Key technological trends include:

- Stability-Oriented Design: Stability is prioritized at every stage, from material selection to packaging design and testing. This ensures that sensors deliver accurate and reliable data even under variable environmental conditions.

- Application-Oriented Customization: Recognizing that each system has unique requirements, modern low pressure sensors are designed for application-specific customization. This includes hardware adjustments, software calibration, and interface optimization for seamless integration.

- Data-Driven Development: Iterative design improvements are guided by experimental evidence and engineering data, ensuring practical and reliable solutions that meet real-world demands.

- Modular and Scalable Solutions: Beyond standard sensor offerings, modular development supports rapid system integration and accelerates product launches, providing flexibility for diverse applications.

Applications Across Industries

Medical Sector: Low pressure sensors are integral to medical equipment such as ventilators, infusion pumps, and non-invasive blood pressure monitors. Precise pressure readings ensure patient safety and effective therapeutic outcomes. MEMS-based sensors, with their small footprint and high sensitivity, are particularly suited for portable and wearable medical devices.

Automotive Industry: In automotive applications, low pressure sensors are used in manifold absolute pressure (MAP) sensors, cabin pressure monitoring, and fuel system management. Accurate low-pressure measurement contributes to engine efficiency, emission control, and driver comfort. Sensors must endure temperature variations, vibrations, and harsh environmental conditions, necessitating robust and reliable designs.

Consumer Electronics: Modern consumer devices, including smartphones and wearable technology, often incorporate low pressure sensors for altitude detection, weather monitoring, and environmental sensing. The integration of compact MEMS sensors allows for multifunctional devices without compromising performance.

Industrial and Environmental Monitoring: Low pressure sensors also find applications in HVAC systems, cleanrooms, and laboratory equipment, where maintaining specific pressure differentials is crucial for process control and safety.

Key Performance Metrics

When selecting or designing low pressure sensors, several performance metrics are critical:

- Sensitivity: The ability of the sensor to detect minute changes in pressure. High sensitivity is essential for applications requiring precise measurements.

- Accuracy and Linearity: Accurate conversion of physical pressure to electrical output with minimal deviation across the measurement range.

- Stability and Drift: Long-term performance consistency under varying environmental conditions, including temperature and humidity changes.

- Response Time: Rapid detection of pressure changes to support real-time monitoring and control.

- Compatibility: Ease of integration with existing system interfaces and electronics, often enhanced through modular designs and custom interfaces.

Wuxi Mems Tech Co., Ltd. emphasizes comprehensive quality control, rigorous packaging, and extensive testing to ensure that each sensor meets these key performance standards while remaining cost-effective.

Advantages of MEMS-Based Low Pressure Sensors

MEMS technology offers several advantages over traditional low pressure sensing approaches:

- Miniaturization allows for compact designs suitable for portable or wearable devices.

- Low power consumption enhances energy efficiency, particularly in battery-powered applications.

- High reproducibility and scalability support mass production with consistent quality.

- Enhanced integration with digital systems enables smart sensing solutions and advanced data analytics.

These advantages make MEMS-based low pressure sensors a preferred choice across medical, automotive, and consumer electronics sectors.

One-Stop Technical Support and Customization

Successful deployment of low pressure sensors requires more than just high-quality hardware. Technical support throughout the development and integration process is crucial. Wuxi Mems Tech Co., Ltd. offers comprehensive guidance, from model selection to interface debugging, ensuring that sensor solutions are effectively tailored to system-specific requirements. By providing one-stop technical support and modular development options, manufacturers can accelerate time-to-market while maintaining optimal performance.

Conclusion

Low pressure sensors serve as the backbone of precision measurement across multiple industries. From ensuring patient safety in medical devices to optimizing engine performance in vehicles and enhancing the functionality of consumer electronics, these sensors provide critical insights that enable smarter, more reliable systems.

English

English Français

Français 中文简体

中文简体