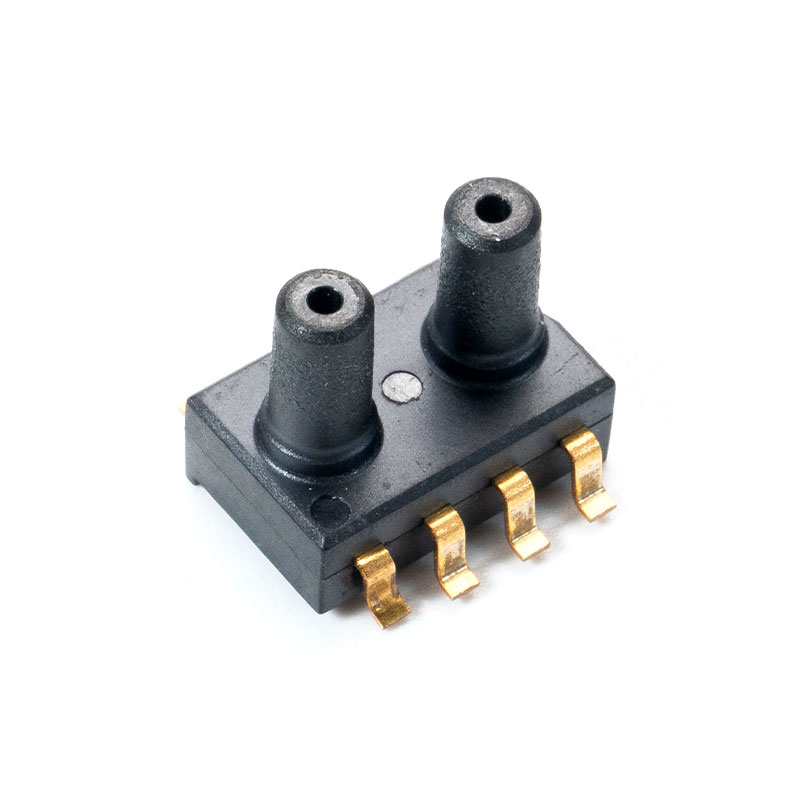

Micro pressure sensor Manufacturers

Micro-pressure sensors are high-precision devices used to detect tiny pressure changes (usually less than 1kPa) and are widely used in fire protection, heating, ventilation and air conditioning (HVAC) and other fields. In the fire protection system, it monitors the residual pressure status of stairwells, antechambers and other areas in real time to ensure that the air pressure in the escape passage meets safety standards and trigger the residual pressure alarm system. In the HVAC field, micro-pressure sensors are used to optimize the efficiency of the ventilation system and adjust the air volume through parameters such as duct pressure and filter pressure difference. The core advantages are high sensitivity, low temperature drift and long-term stability, which can meet the needs of weak pressure monitoring in complex environments.

-

Understanding Medium Pressure Sensors A Medium Pressure Sensor is a precision sensing device designed to measure pressure levels that fall between low-pressure and high-pressure ranges. These sensors are widely used in systems where stable, accurate pressure monitoring is essential but extreme pressure resistance is no...

VIEW MORE

-

Pressure sensing is a fundamental capability that bridges the physical and digital worlds, enabling everything from weather forecasting to life-saving medical interventions. Among the various types, the absolute pressure sensor holds a unique and critical position. But what exactly sets it apart? Unlike sensors that me...

VIEW MORE

-

In the rapidly evolving landscape of modern engineering and electronic design, the demand for precise, reliable, and compact sensing solutions is at an all-time high. Among the myriad of technologies available, the MCP Pressure Sensor has emerged as a critical component for a wide array of applications, ranging from in...

VIEW MORE

Why Micro Pressure Sensors Are Essential for Next-Generation Sensing Technologies?

Micro pressure sensors have emerged as a critical component in modern sensing technologies, providing precise measurement capabilities in applications where traditional sensors cannot meet stringent accuracy, size, and stability requirements. These devices, also referred to as MEMS micro pressure sensors, operate on the principle of detecting minute pressure variations with high sensitivity, making them indispensable in medical, automotive, and consumer electronics sectors. The evolution of micro pressure sensors has not only improved measurement accuracy but has also enabled the development of more compact, energy-efficient, and multifunctional systems.

Fundamentals of Micro Pressure Sensors

A micro pressure sensor typically consists of a sensing element, signal conditioning circuitry, and packaging that protects the device while maintaining its sensitivity. Most micro pressure sensors today rely on MEMS (Micro-Electro-Mechanical Systems) technology, which allows integration of mechanical elements, sensors, and electronics on a silicon substrate. This miniaturization ensures that sensors can detect extremely small pressure variations, often in the range of micro-Pascals to kilo-Pascals, with high precision.

The key working principles include piezoresistive, capacitive, and optical sensing mechanisms:

- Piezoresistive micro pressure sensors detect changes in resistance due to mechanical stress induced by pressure on a diaphragm. They are widely favored for their robustness and ease of integration with electronic circuits.

- Capacitive micro pressure sensors measure changes in capacitance caused by diaphragm displacement under pressure. These sensors offer high resolution and low temperature sensitivity.

- Optical micro pressure sensors rely on variations in light transmission or reflection caused by pressure-induced deformation, providing immunity to electromagnetic interference.

Core Advantages and Industry Impact

The adoption of micro pressure sensors has transformed multiple industries by enabling precise, real-time monitoring and control. Some key advantages include:

High Accuracy and Sensitivity

Micro pressure sensors provide exceptional sensitivity to minute pressure variations. Devices such as the MCP-H10, with ±1.5% VFSS accuracy, demonstrate the ability to deliver stable, repeatable signals even under varying environmental conditions.

Miniaturization and Integration

The small footprint of micro pressure sensors allows integration into compact medical devices, wearable electronics, and automotive systems without compromising performance. This facilitates the design of multifunctional systems that were previously unattainable.

Cost-Effective Performance

Despite their sophisticated functionality, micro pressure sensors are manufactured to provide high performance at competitive prices. Wuxi Mems Tech Co., Ltd. focuses on the research and development of MEMS pressure sensors, fully embodying this philosophy by combining professional R&D, efficient production management, and rigorous testing.

Reliability in Harsh Environments

Modern micro pressure sensors are designed to maintain stability under temperature variations, mechanical stress, and long-term operational use. This reliability makes them suitable for medical monitoring, automotive safety systems, and industrial instrumentation.

Quality Management and Manufacturing Excellence

Ensuring consistent sensor performance starts with stringent quality management. Wuxi Mems Tech Co., Ltd. emphasizes adherence to ISO quality standards throughout the production process. Every micro pressure sensor undergoes:

- Zero/full-scale calibration to ensure baseline and maximum pressure readings are accurate.

- Temperature drift testing to verify performance stability under variable environmental conditions.

- Long-term stability evaluation to guarantee that batch-to-batch variations remain minimal, preserving sensor reliability over its operational life.

These measures ensure that the sensors consistently meet or exceed performance specifications, whether in medical devices or automotive pressure monitoring systems.

Manufacturing Capability and Process Control

The production of micro pressure sensors demands precise control over every stage, from prototyping to mass production. Wuxi Mems Tech Co., Ltd. operates a 2,000 m² standardized facility with comprehensive in-house capabilities, including:

- Packaging and soldering, ensuring device protection without affecting sensitivity.

- Temperature compensation to stabilize output under fluctuating thermal conditions.

- Performance calibration, guaranteeing that output meets design specifications.

- Full-process quality control, minimizing defects and enhancing product reliability.

Furthermore, their production line supports rapid response to customization requests, allowing clients to tailor packaging, pressure range, and output formats according to specific applications.

Applications Across Key Sectors

Medical Industry

In medical devices, micro pressure sensors are crucial for non-invasive blood pressure monitoring, respiratory measurement, and infusion systems. Their miniaturized form factor and high sensitivity allow accurate physiological measurements while maintaining patient comfort.

Automotive Sector

Micro pressure sensors enable precise monitoring of fuel systems, tire pressure, and engine performance. Their integration ensures safer, more efficient vehicle operation while meeting strict regulatory requirements.

Consumer Electronics

Wearable devices and smartphones increasingly rely on micro pressure sensors to track altitude, detect environmental pressure changes, and support health monitoring features. The small size and low power consumption of these sensors are critical for portable applications.

Customization and Market Adaptability

The ability to customize micro pressure sensors enhances their utility across diverse applications. Wuxi Mems Tech Co., Ltd. offers flexible solutions that enable rapid adaptation of sensor designs to meet the following needs:

- Specific pressure ranges, from micro to medium pressures.

- Varied output formats compatible with client systems.

- Specialized packaging for integration into compact or rugged devices.

This adaptability strengthens the competitive advantage of manufacturers and supports innovation in emerging technologies such as autonomous vehicles, advanced medical diagnostics, and smart wearables.

Future Trends and Technological Advancements

The future of micro pressure sensors is driven by continuous advancements in MEMS technology, materials science, and integration techniques. Anticipated trends include:

Enhanced Sensitivity and Accuracy

Ongoing development aims to reduce noise, improve linearity, and expand measurement ranges without increasing device size.

Wireless and IoT Integration

Combining micro pressure sensors with wireless communication enables real-time data collection and analytics for smart devices and industrial monitoring.

Energy Efficiency

Lower power consumption is crucial for wearable and portable applications, extending device longevity while maintaining performance.

Multi-Parameter Sensing

Future sensors may integrate pressure measurement with temperature, humidity, and chemical detection, providing comprehensive environmental insights from a single device.

Conclusion

Micro pressure sensors have become an essential technology for modern industries, providing unmatched precision, miniaturization, and reliability. Their integration into medical devices, automotive systems, and consumer electronics demonstrates their versatility and significance.

English

English Français

Français 中文简体

中文简体